Seleziona un prodotto e individua versione, stile e optional, per configurare il sistema OMIS più adatto ai tuoi bisogni.

Metodo produttivo

Ricerca, tecnologia, esperienza.

Così costruiamo l’eccellenza.

Ricerca costante e

Lean Production

Produciamo bene perché pensiamo e organizziamo i processi in modo corretto. Siamo costantemente focalizzati sul miglioramento del prodotto che aumenti il suo valore per il cliente e sulla riduzione degli sprechi. Dalla Lean Production al Lean Thinking: una filosofia che si diffonde a tutti i livelli e in ogni ufficio del gruppo.

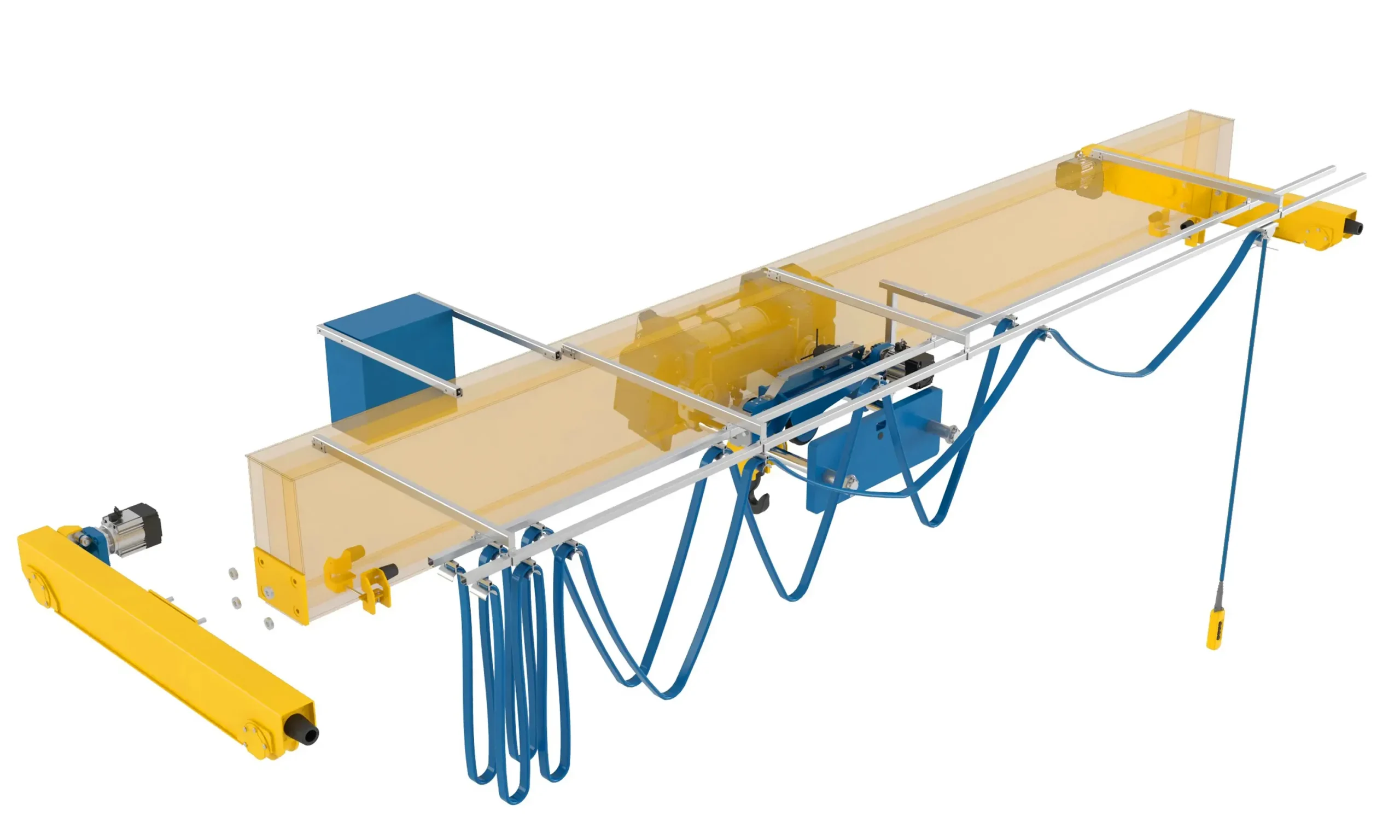

Strumenti all’avanguardia,

in ciascuna fase

Aggiornamento tecnologico e innovazione continui caratterizzano anche i macchinari destinati a singole fasi produttive o di rifinitura: stazioni di saldatura robotizzate, macchine di taglio al plasma, tunnel di verniciatura, forni di asciugatura, centri di lavoro, torni a controllo numerico, dentatrici e rettifiche, serviti anche da caricatori automatici.

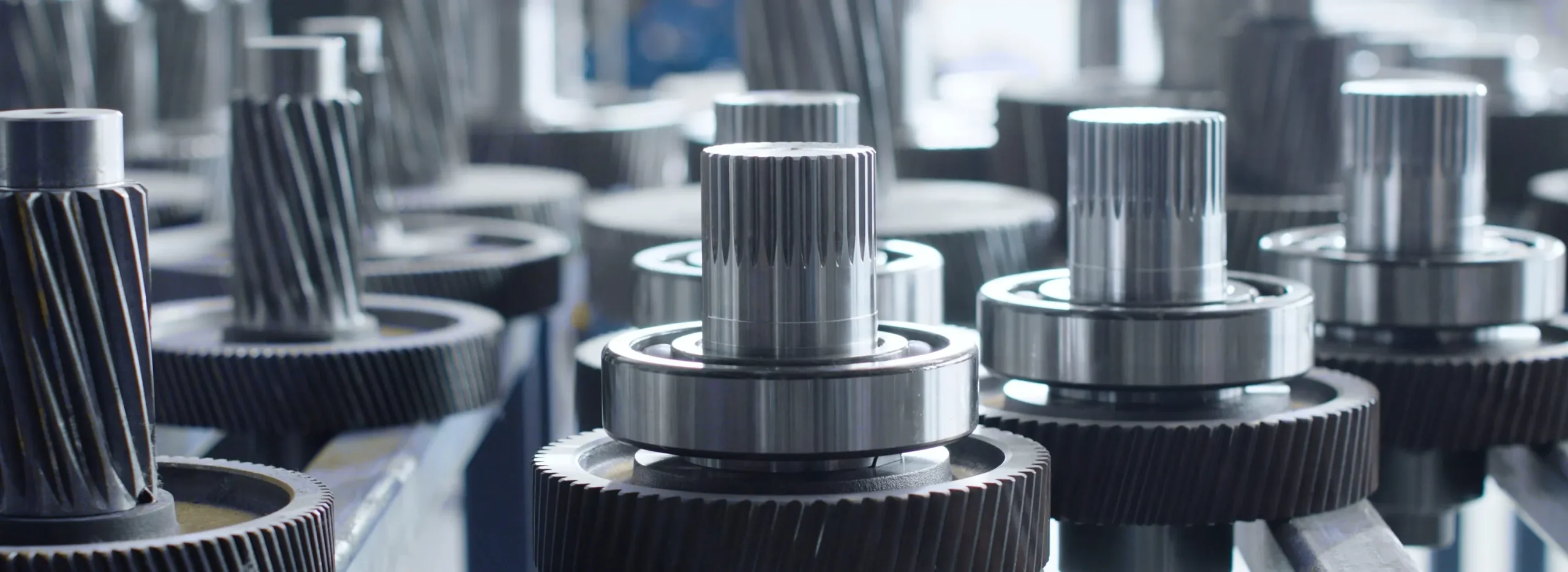

Finiture e lavorazioni

semi-artigianali

Nella precisione portata fino al dettaglio, nella cura estrema delle finiture, niente può sostituire l’esperienza e le capacità delle persone di OMIS. Un patrimonio umano e tecnico prezioso, perfettamente integrato e coordinato con il ricorso a soluzioni industriali futuristiche.

Nati per innovare.

Cresciuti per innalzare valori.

OMIS è un produttore di eccellenza, un partner sicuro e affidabile, un gruppo che ricerca e pratica responsabilità e sostenibilità. Tecnologia, dialogo, solidi principi e sguardo rivolto al futuro alimentano strategie, approccio industriale, consapevolezza ambientale.

Configuratore OMIS.

Scegli le caratteristiche della soluzione perfetta per te.

OMIS informa e risponde.

Risposte pronte, consigli utili, consulenza e comunicazioni efficaci e veloci. Cerca l’argomento di tuo interesse e scopri le spiegazioni offerte alle domande più frequenti dei nostri clienti.

Ciascun progetto è un testimonial.

Un intervento multiplo che risponde alle necessità dettate dall’aumento di superficie e dalla nascita di una intera nuova linea produttiva. Leader nella spianatura e nel taglio di lamiere in acciaio al carbonio, da coils laminati a caldo, fin dal 1980, con un altissimo grado di specializzazione che riesce a soddisfare ogni minima esigenza dei propri clienti, Sidastico ha stabilito una…

Nexteel è un nuovo progetto del trentino FAE Group. Un’azienda giovane, che eccelle nella progettazione e costruzione di macchinari e prodotti destinati alla carpenteria medio-pesante, con un approccio innovativo ai processi e uno sguardo tecnologico decisamente rivolto al futuro. Oltre a laser in fibra, attrezzature robotizzate e centri verticali lo stabilimento ha sviluppato un efficiente settore logistico interno per la…

Un carroponte da 80 tonnellate ad altissimo grado di automazione per movimentare le bobine e garantire sicurezza e precisione, ogni giorno. Un edificio industriale grande e particolare, con esigenze fuori dall’ordinario, da attrezzare con un carroponte bitrave progettato ad hoc. Sfida accettata e vinta da OMIS, al fianco di Pro-gest, il colosso italiano della carta riciclata. Lo stabilimento in questione…

OMIS World

Dalle emergenze alla formazione,

capillari e tempestivi.

Dal pronto intervento alla manutenzione programmata, fino all’ammodernamento tecnologico: ci prendiamo cura del tuo impianto a 360 gradi.

Il tuo impianto è importante e deve funzionare perfettamente, a lungo. Studiamo e organizziamo fin nei dettagli le soluzioni migliori per prendercene cura. OMIS ha le competenze e l’esperienza per assicurarsi gli impianti durino nel tempo, preservando le condizioni operative in cui si trovavano nel primo giorno d’uso.