From consulting to engineering and commissioning, OMIS works closely with customers. Given the critical working conditions for machines and operators, the prior sharing of the analysis is fundamental for better operational results. Bespoke crane design and optimised handling lead to highly customised and efficient solutions.

OMIS technology and strength, the frontier of waste handling.

Reliable, powerful, precise, able to operate at high speeds, without interruption, for long periods. And always perfectly suited to the function and structure of use, because they are designed, manufactured and tested according to specific customer requirements.

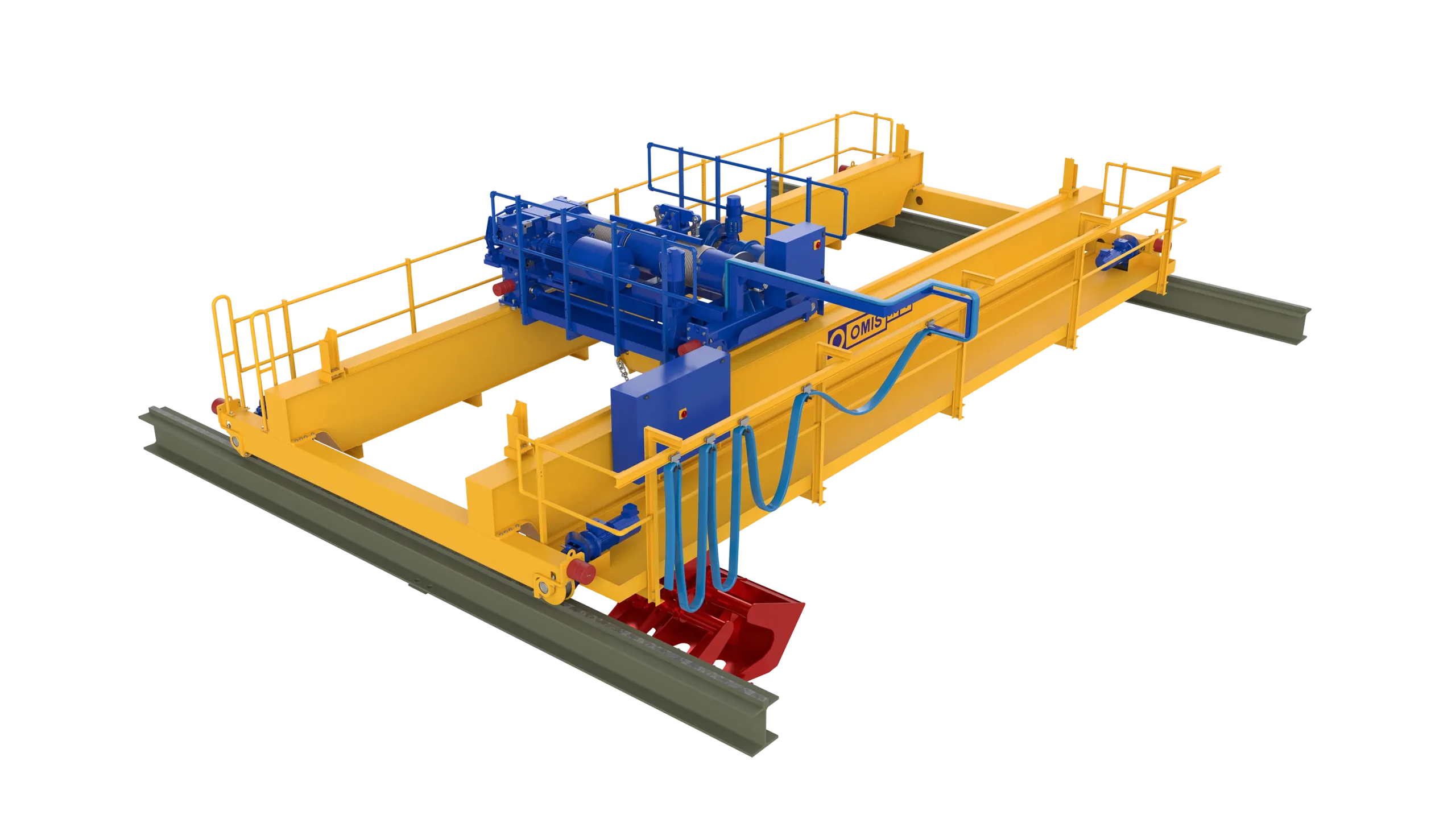

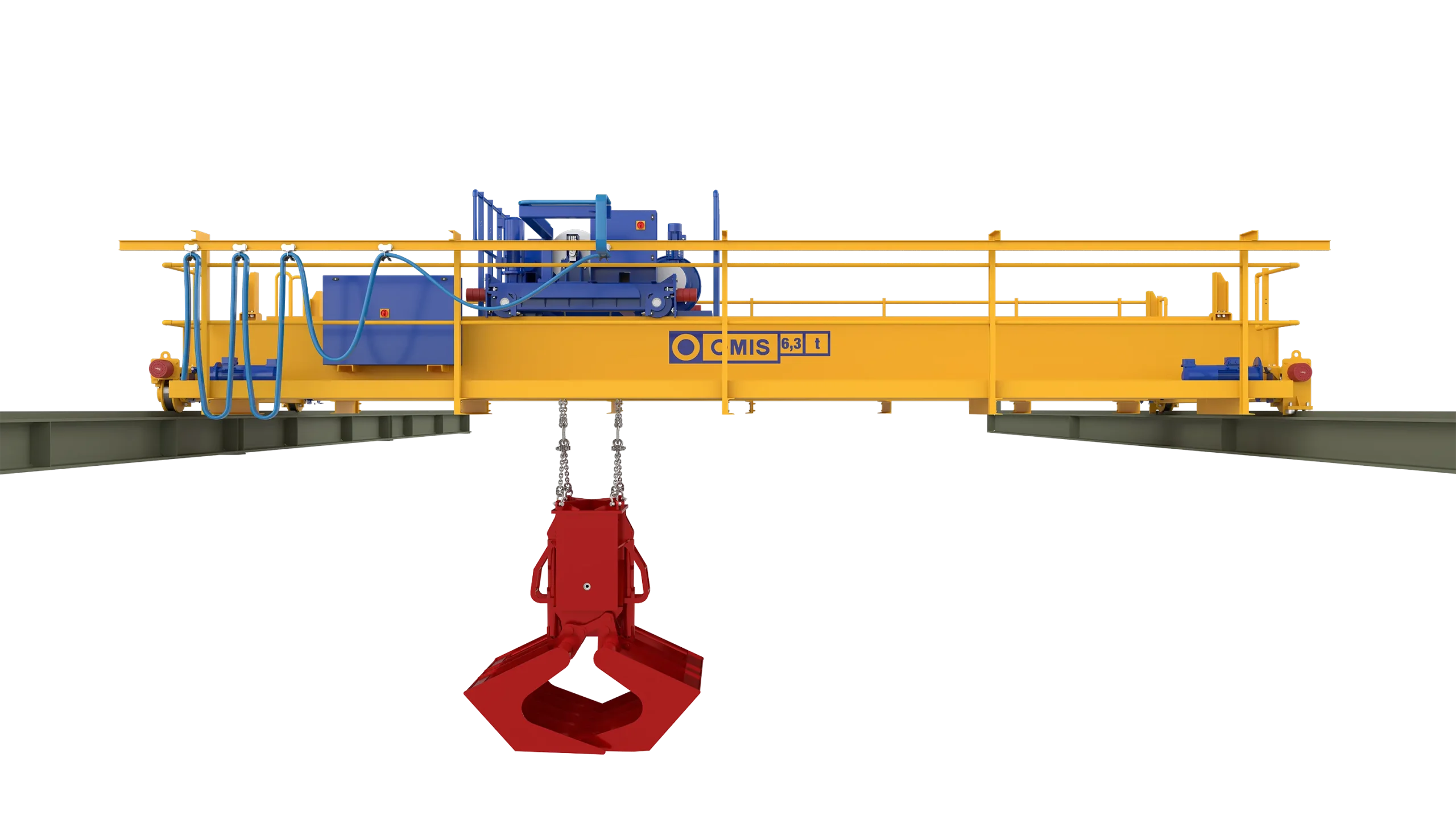

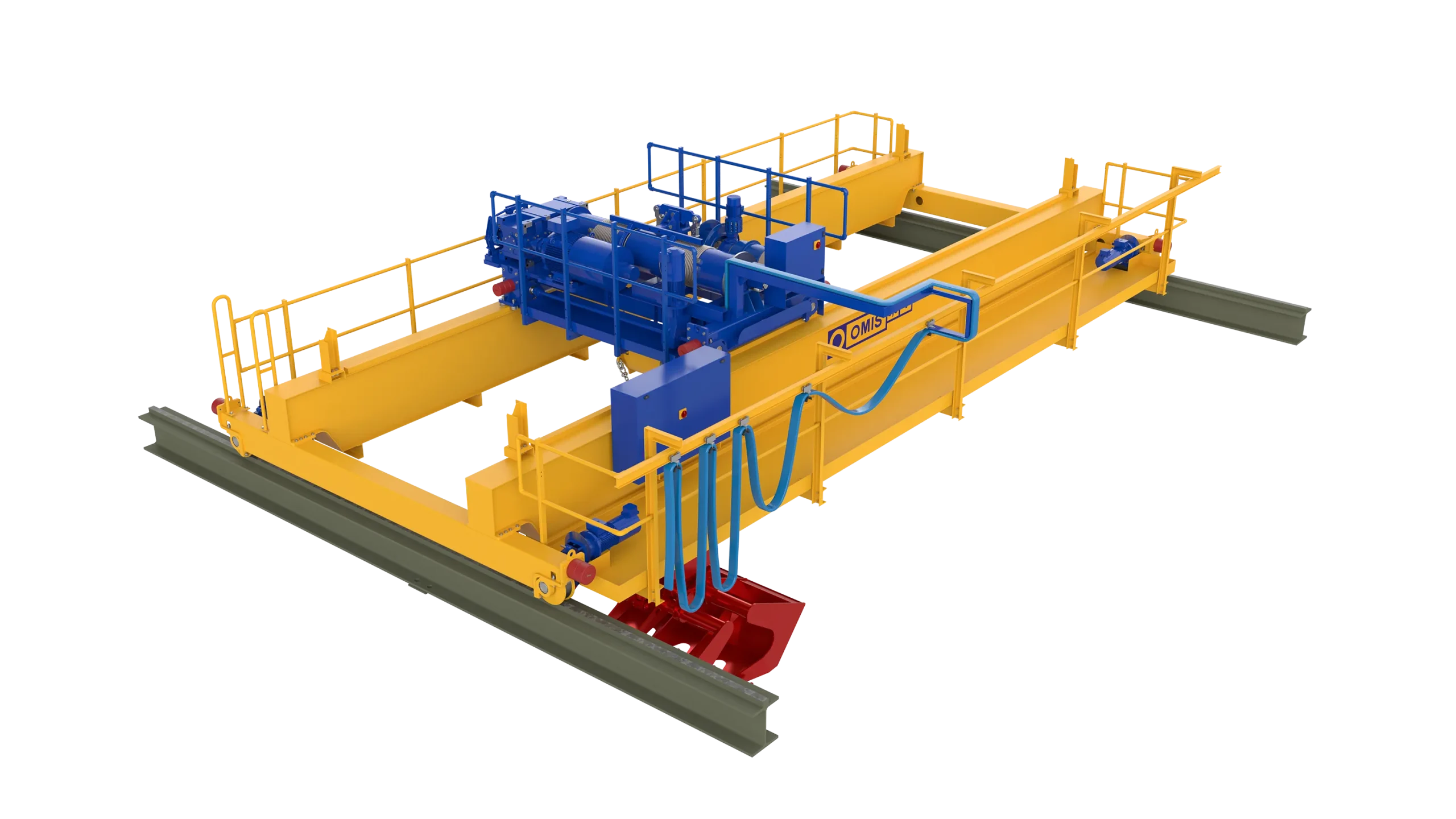

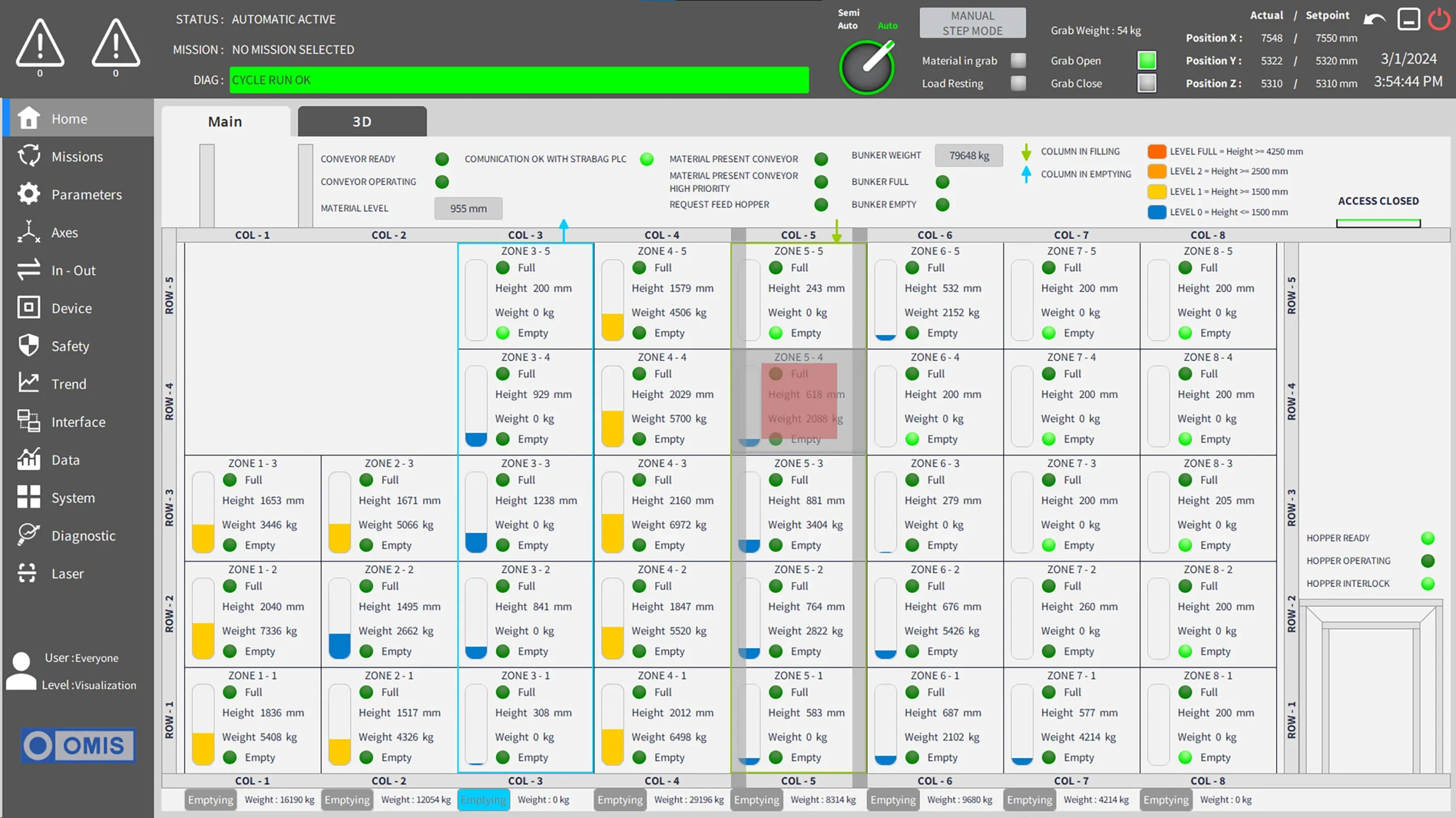

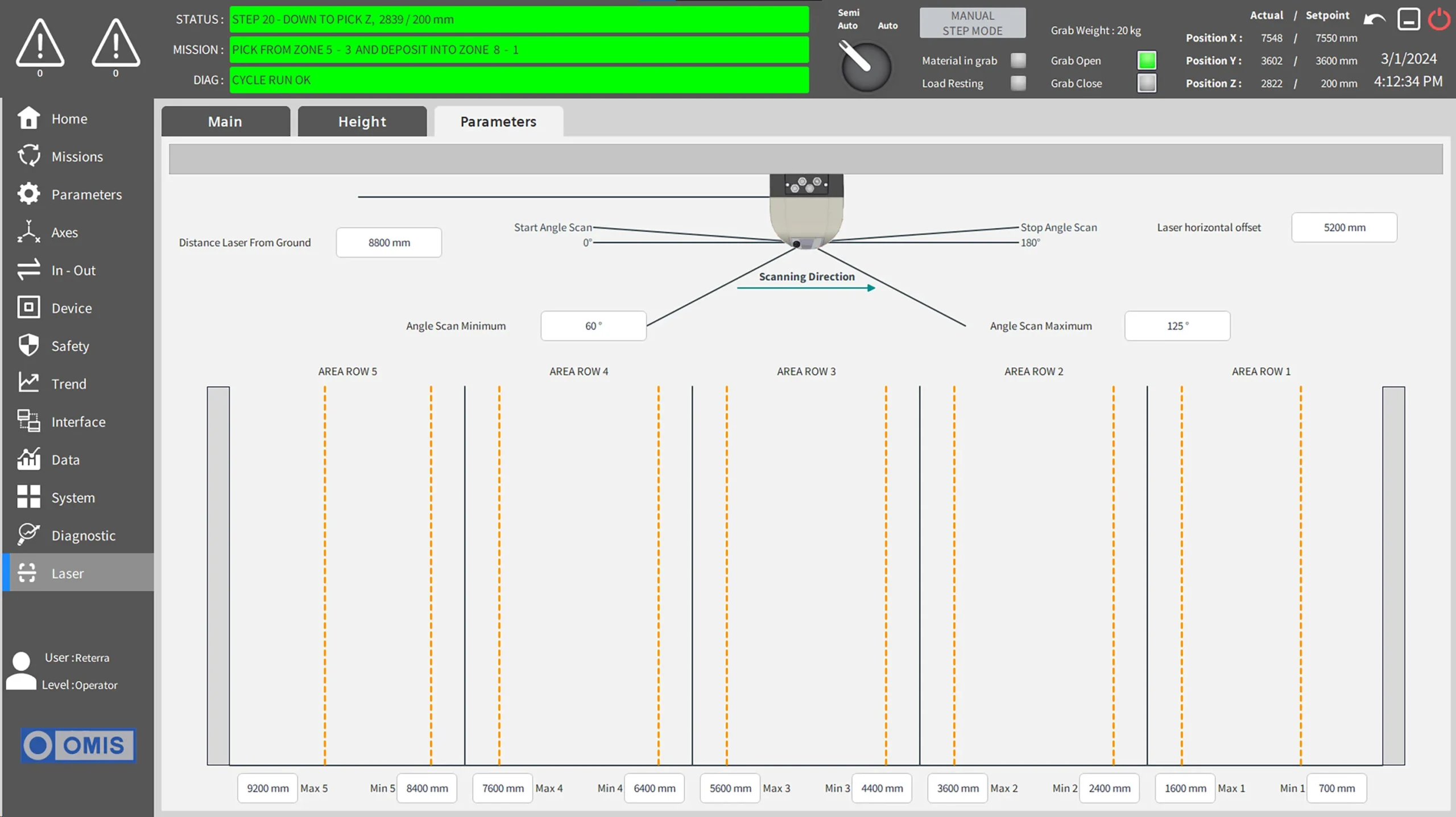

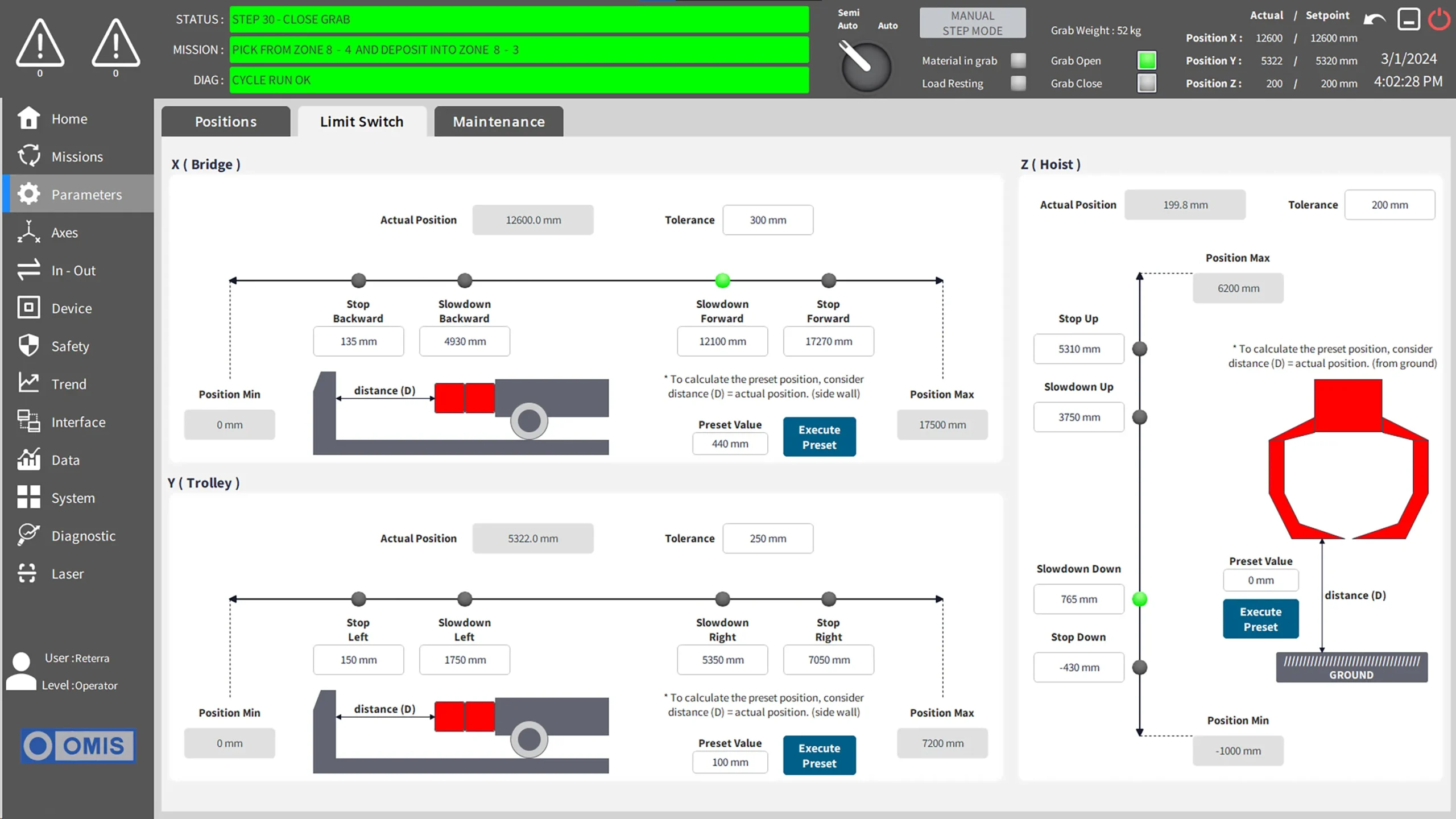

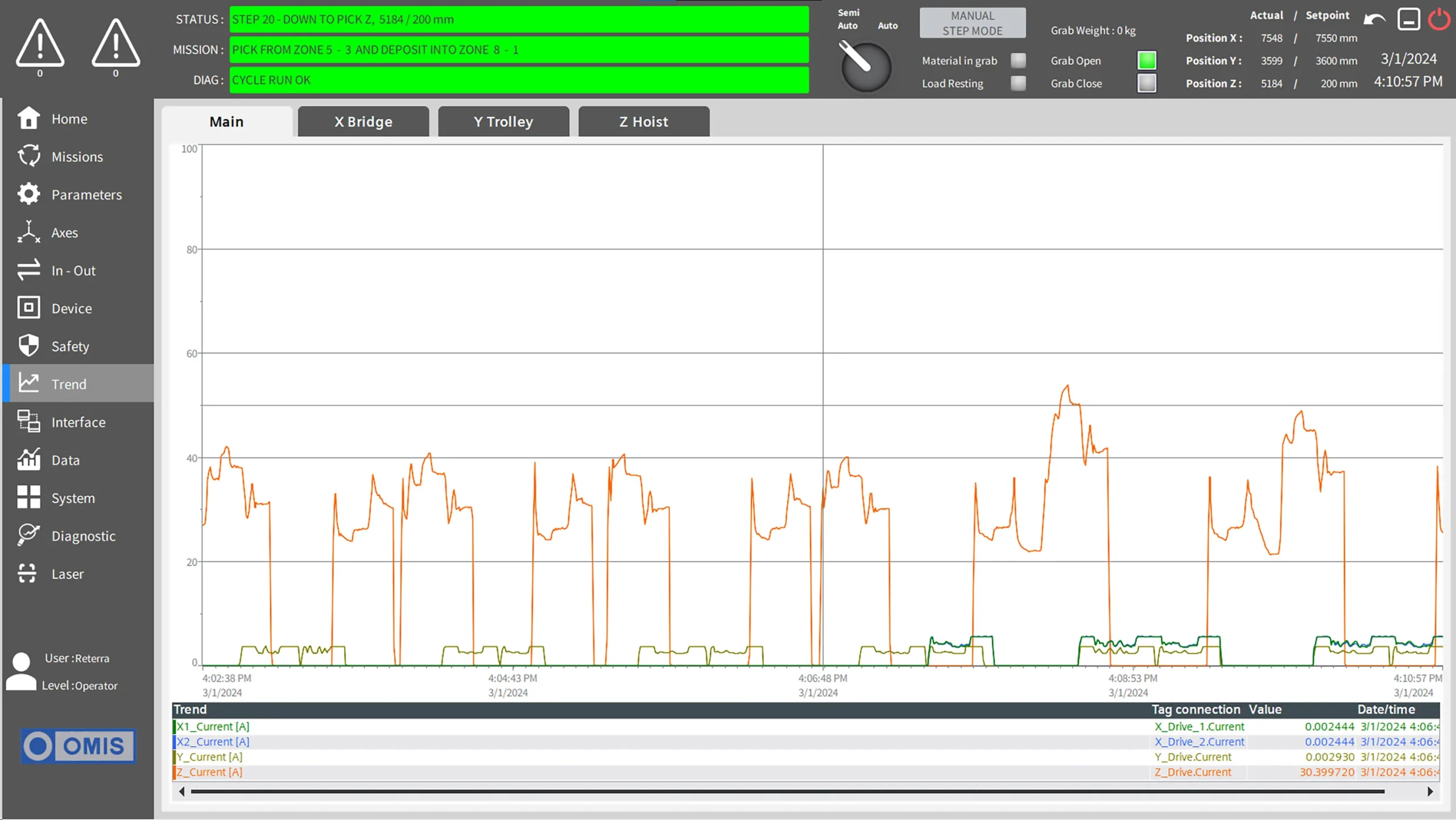

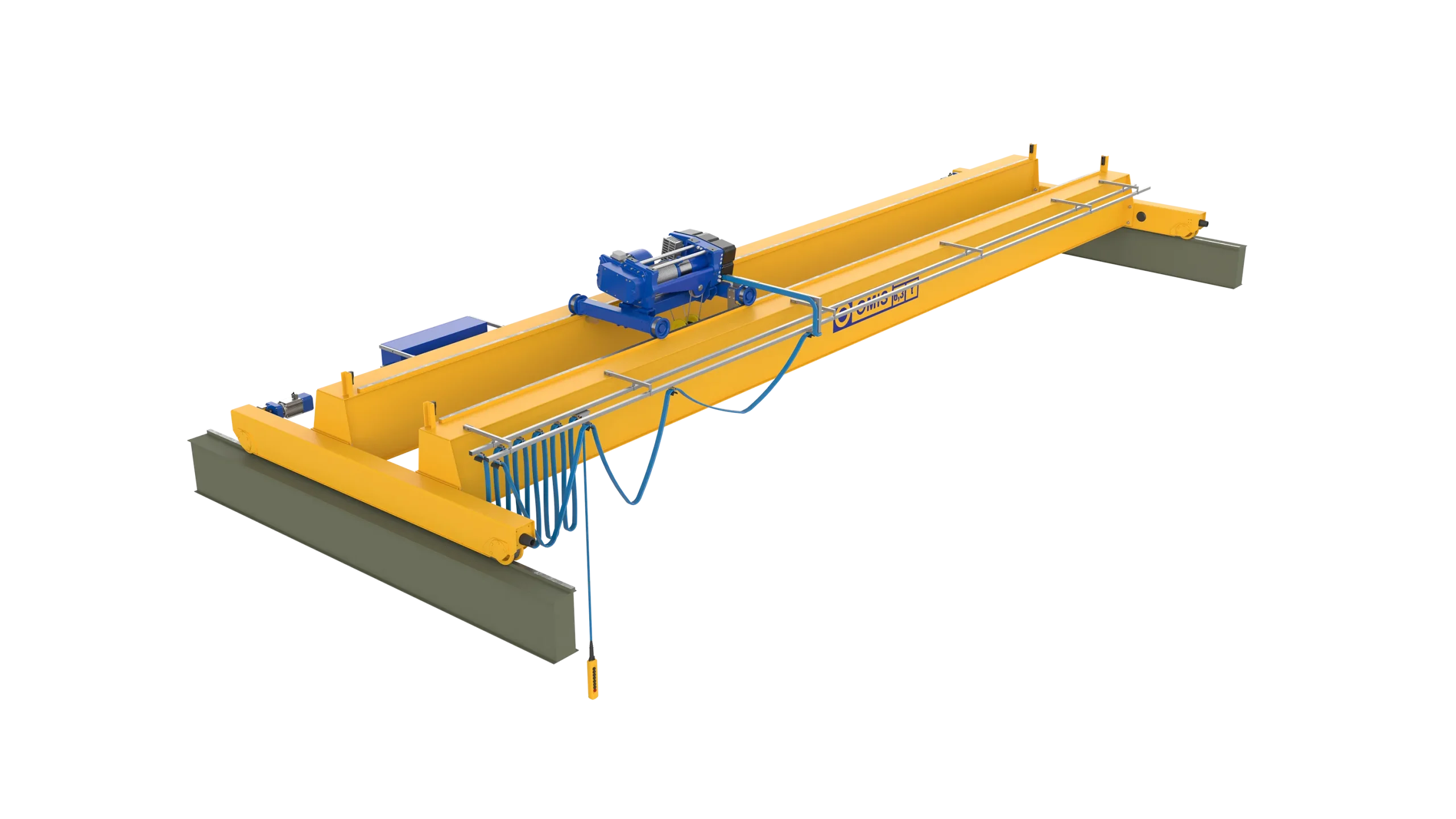

OMIS double-girder overhead cranes for waste handling meet the toughest tests dictated by an extreme working environment with maximum effectiveness, thanks to top-quality components and an advanced smart automation system: state-of-the-art technology, from control and command via safety PLCs, to supervision with specially developed HMIs, to interfacing with management systems and SCADA.

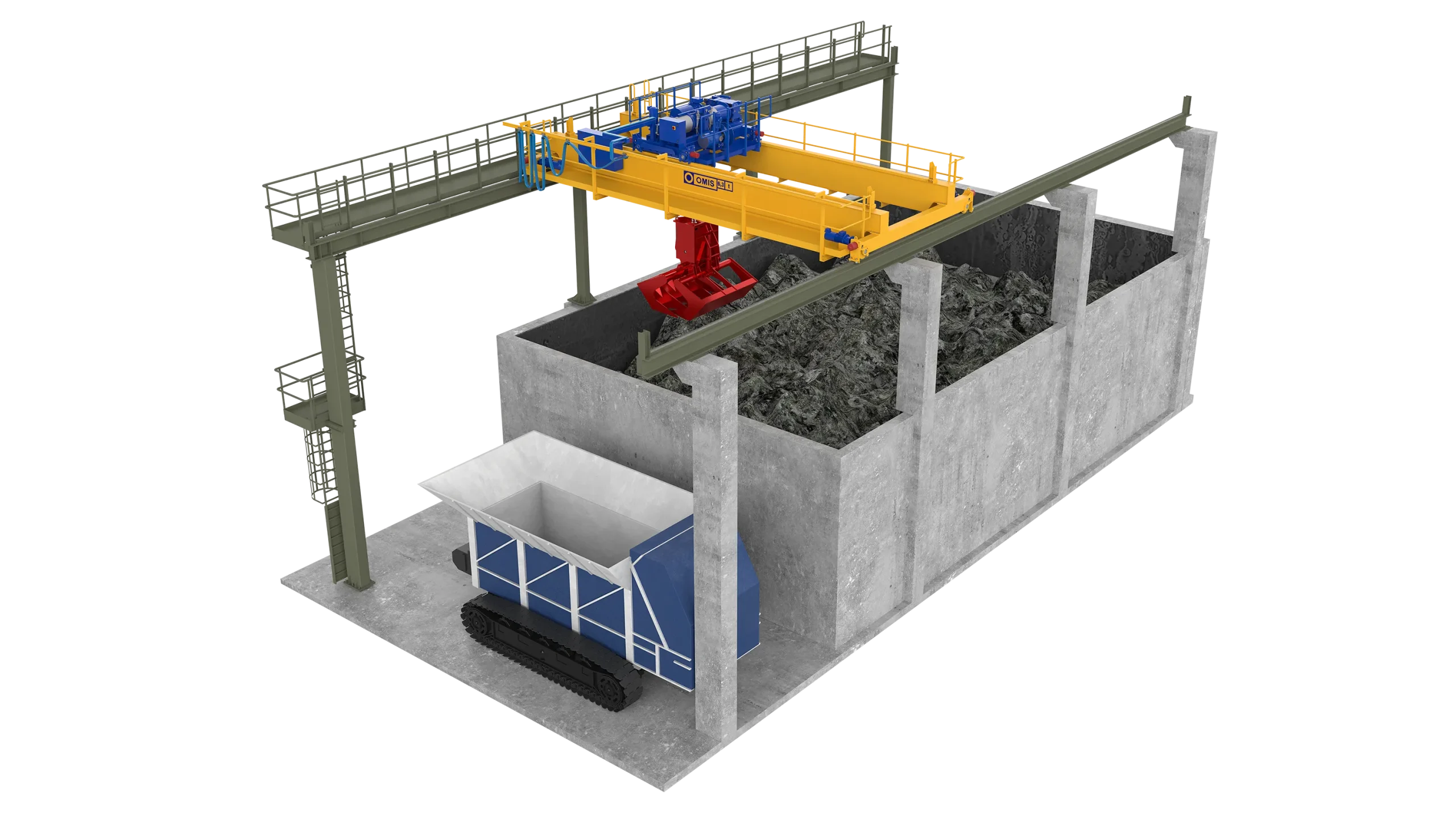

We manufacture automatic cranes for handling organic or multi-material waste, for organic waste treatment systems, for energy production plants from wood chips and BIOMASS in general, and for MSW disposal plants such as incinerators and waste-to-energy plants.

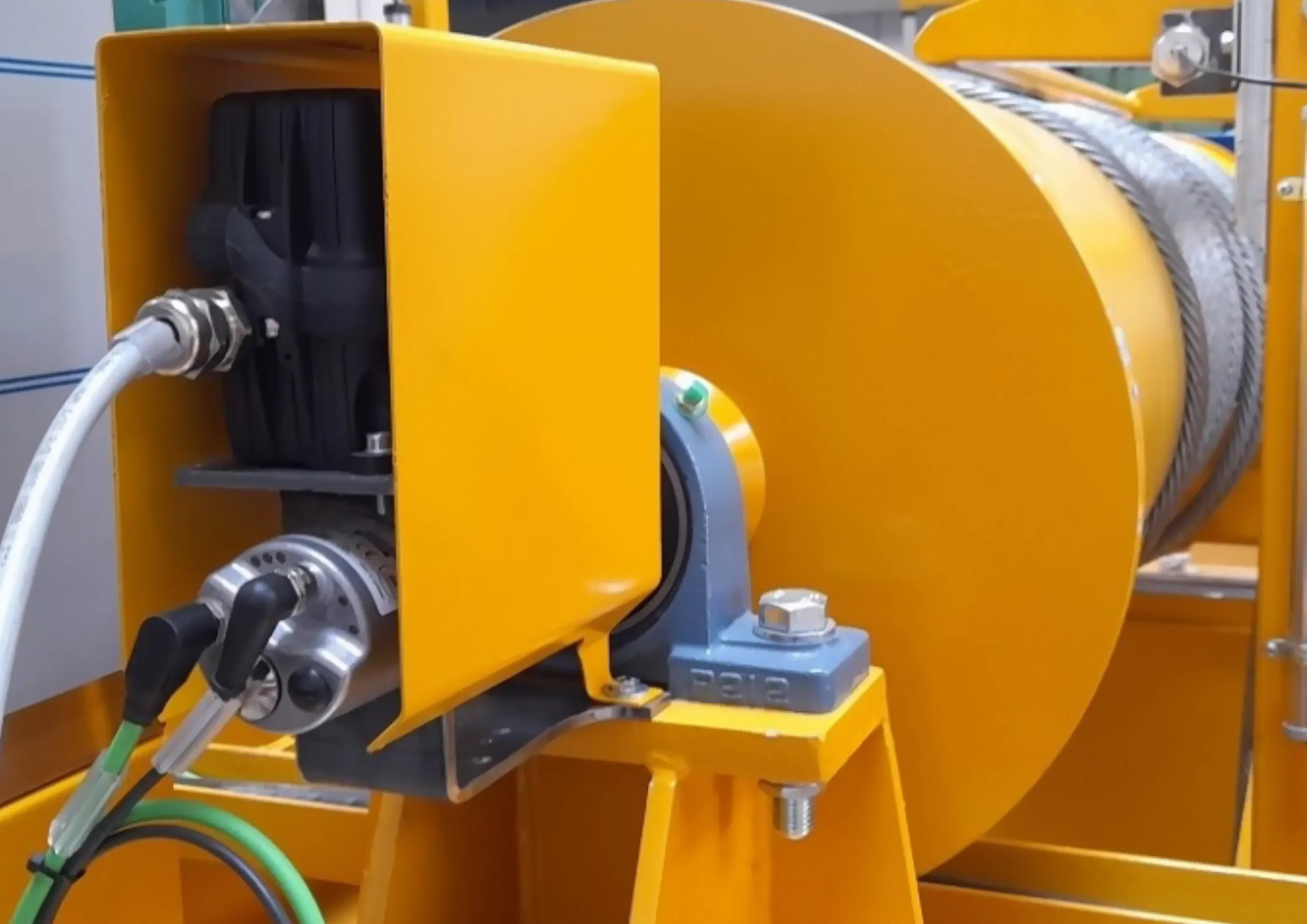

In plants for the disposal and recycling of waste with organic content, efficiency, accuracy and process safety are a must. Here, dirt, heat and humidity define an aggressive environment, which demands the use of handling systems with the highest requirements, down to the last detail. Continuous cycles and highly aggressive environments require the selection of high quality components and very precise and generous mechanical, electrical and structural designs.

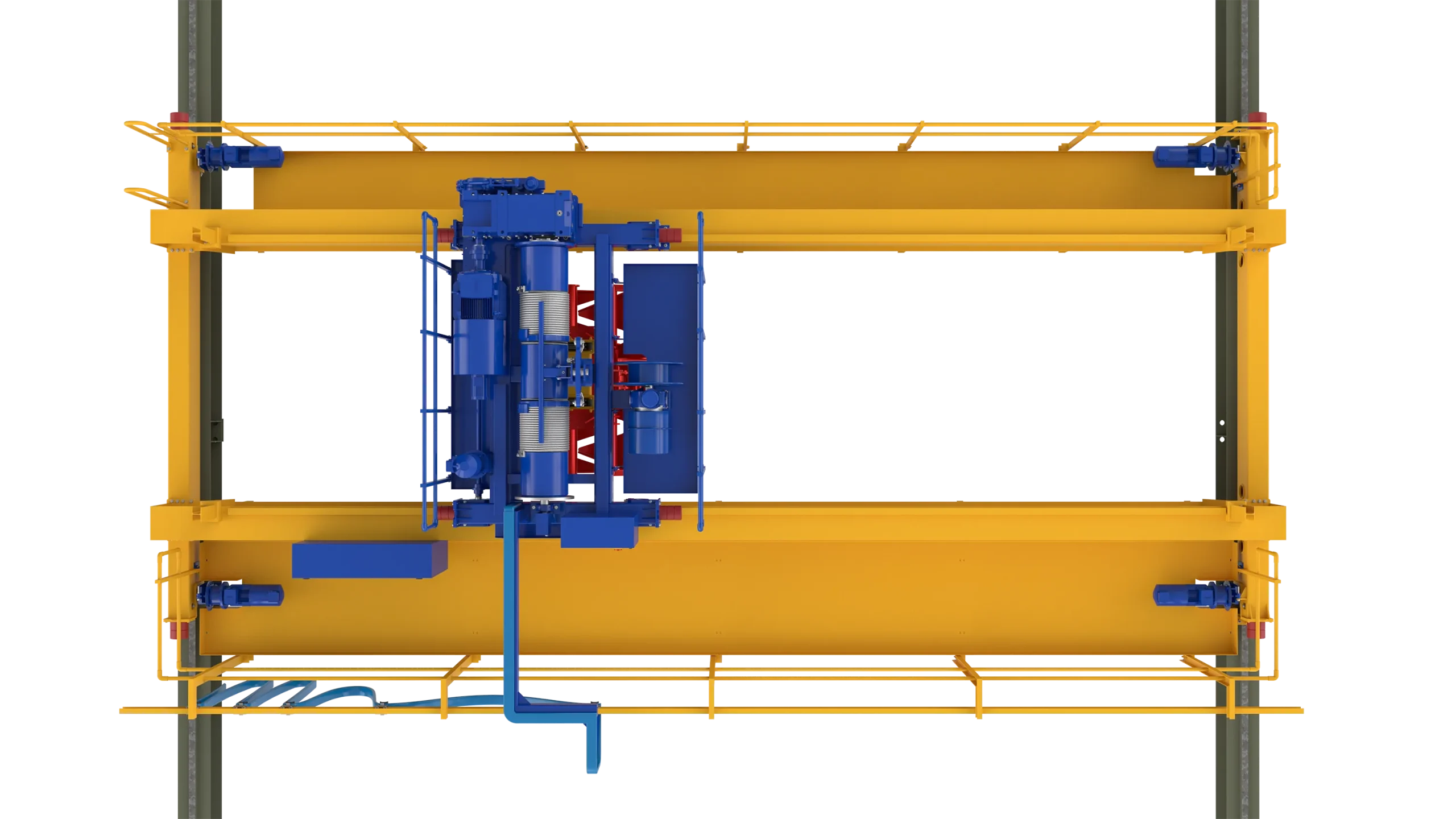

OMIS meets all the needs of the industry in the most efficient way by providing systems with a load capacity of up to 40 tonnes and a span of up to 20 metres, equipped with an OMIS double-reeved open barrel hoist with a swivel gripper. This ensures maintenance work in high humidity conditions, the replacement of rollers and other continuous machine components, the transport of machine parts and service and maintenance work in all working areas.

Automation and customised design minimise human intervention in hazardous conditions and enable the equipment to cope with any specific operating situation.

The cranes operate 24/7, guaranteeing the continuity and reliability of incineration and composting processes and excellent performance in picking, handling, mixing and feeding waste-to-energy plants.

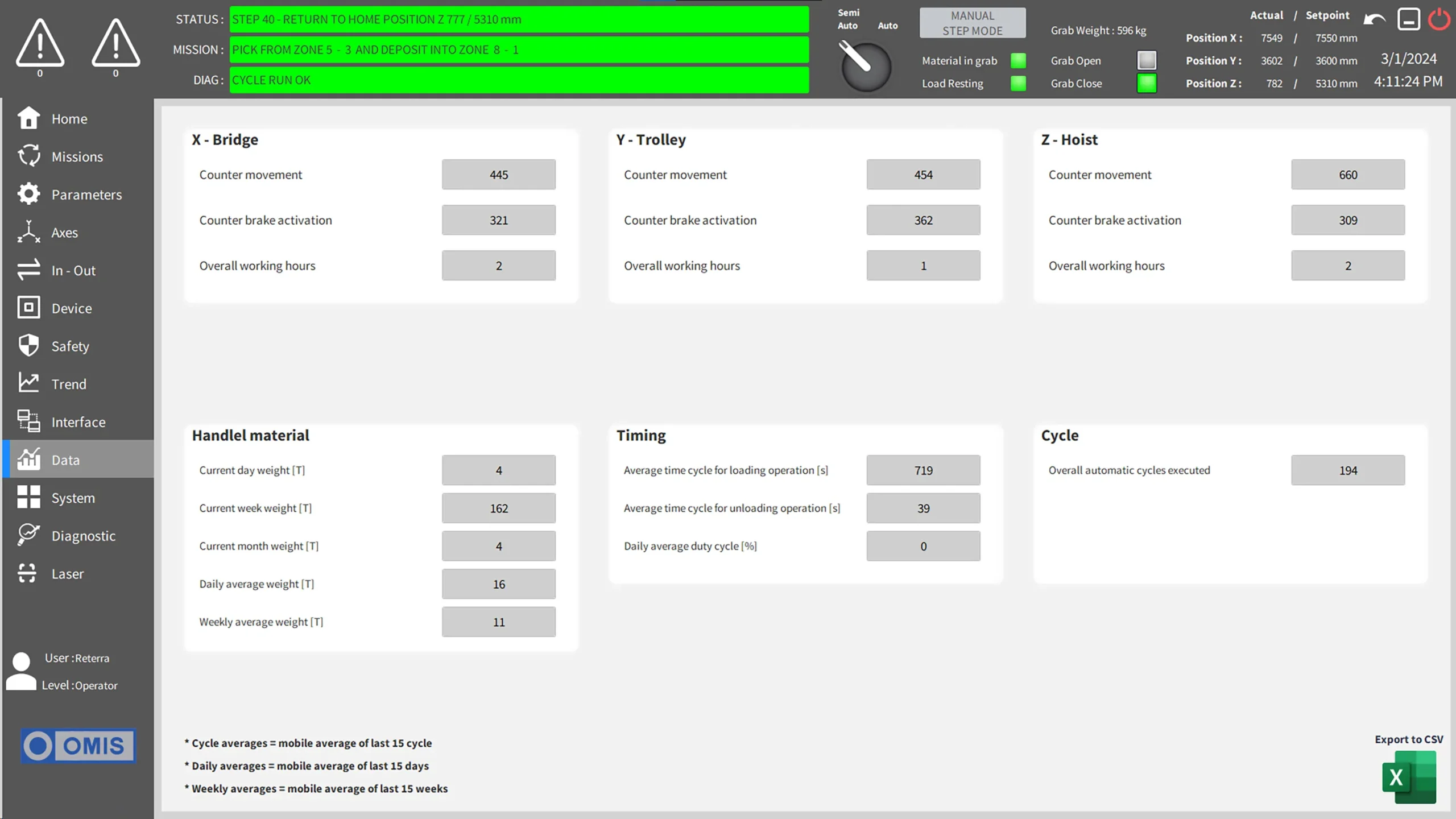

Initial sizing and cycle times are studied and designed with the utmost care, to ensure high and constant productivity with minimum maintenance and thus secure the return on investment.

Particular attention is paid to maintenance issues: the use of easily accessible and replaceable mechanical parts and an open-type electrical design logic allow easy preventive maintenance, rapid intervention and reduced operating costs.

Benefits

Know how

Precision

Integrated oscillation control systems enable fast and precise bucket movement, helping to avoid costly damage to the equipment. They also minimise load sway and increase control during positioning, thus reducing cycle times.

Safety

The smart automation system allows you to select full or semi-automation. Positioning the load thus becomes safe and easy: collisions are avoided, the operator is less fatigued and the risk of failure is reduced. Monitoring systems allow the process to be controlled from the operator’s workstation or from a central control room away from the waste pit.

Automation

Different automation modes precisely meet different operational requirements, optimising processes and the safety of people and equipment, and increasing productivity.

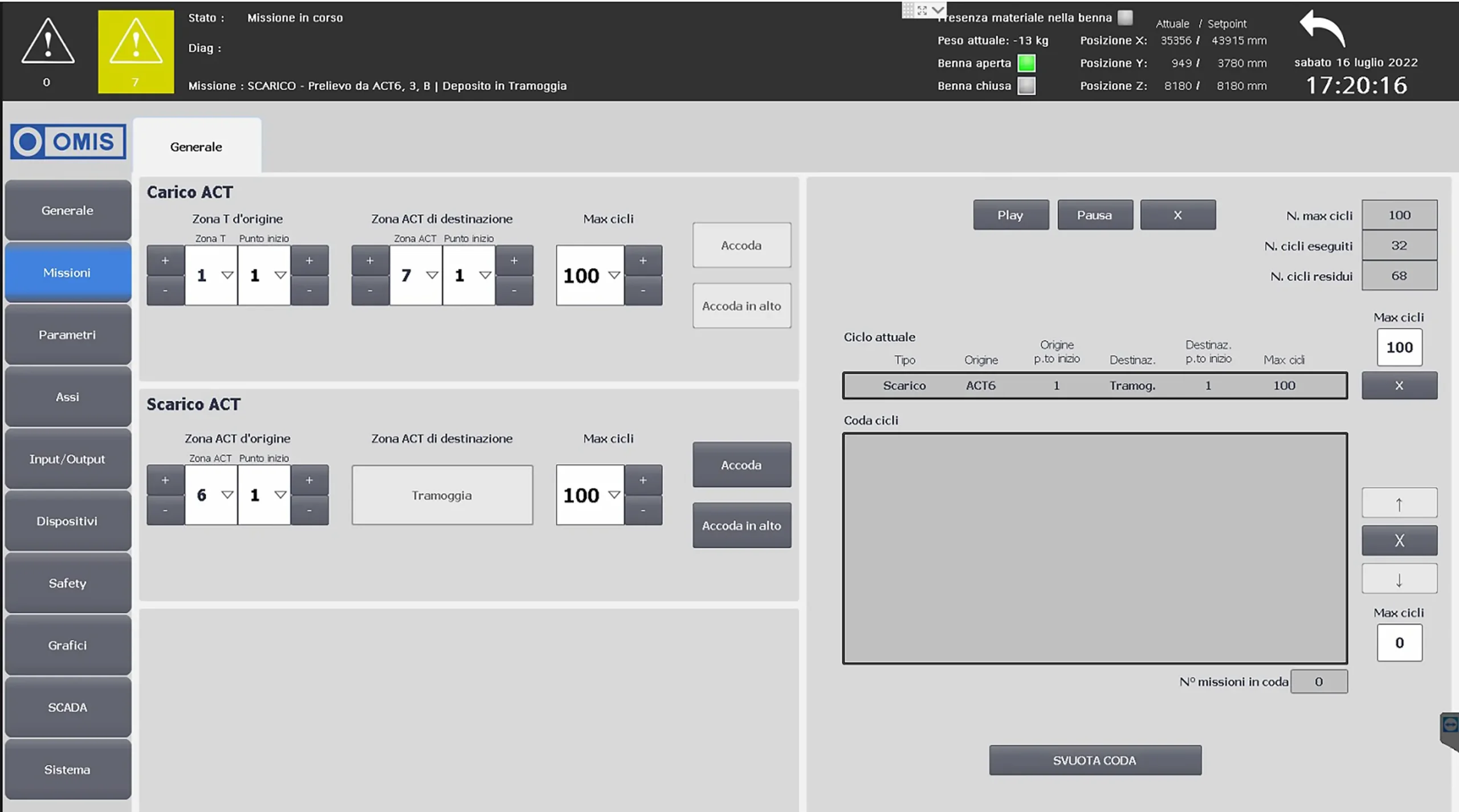

Mission list mode: the crane cyclically carries out the missions set by the operator.

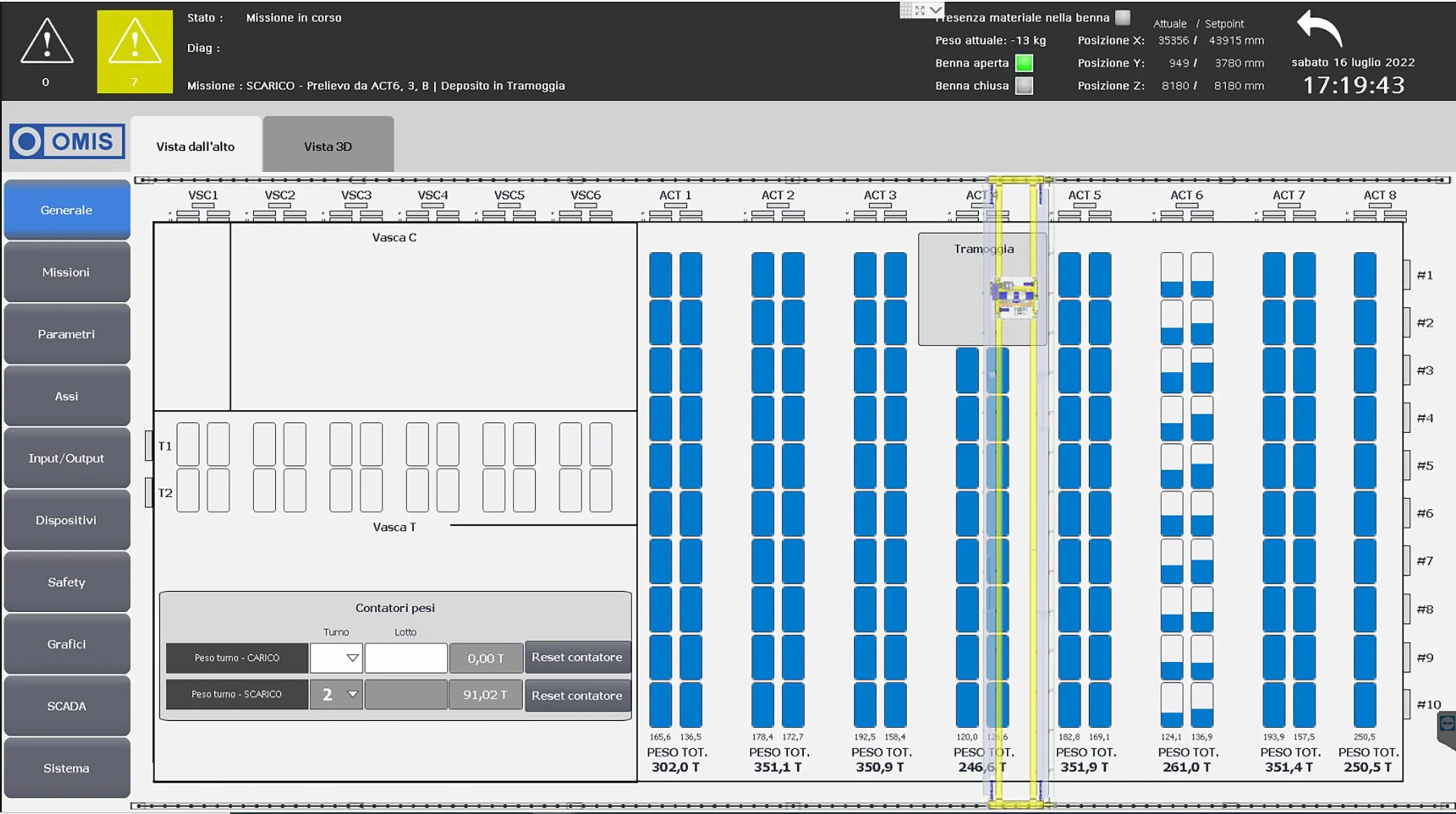

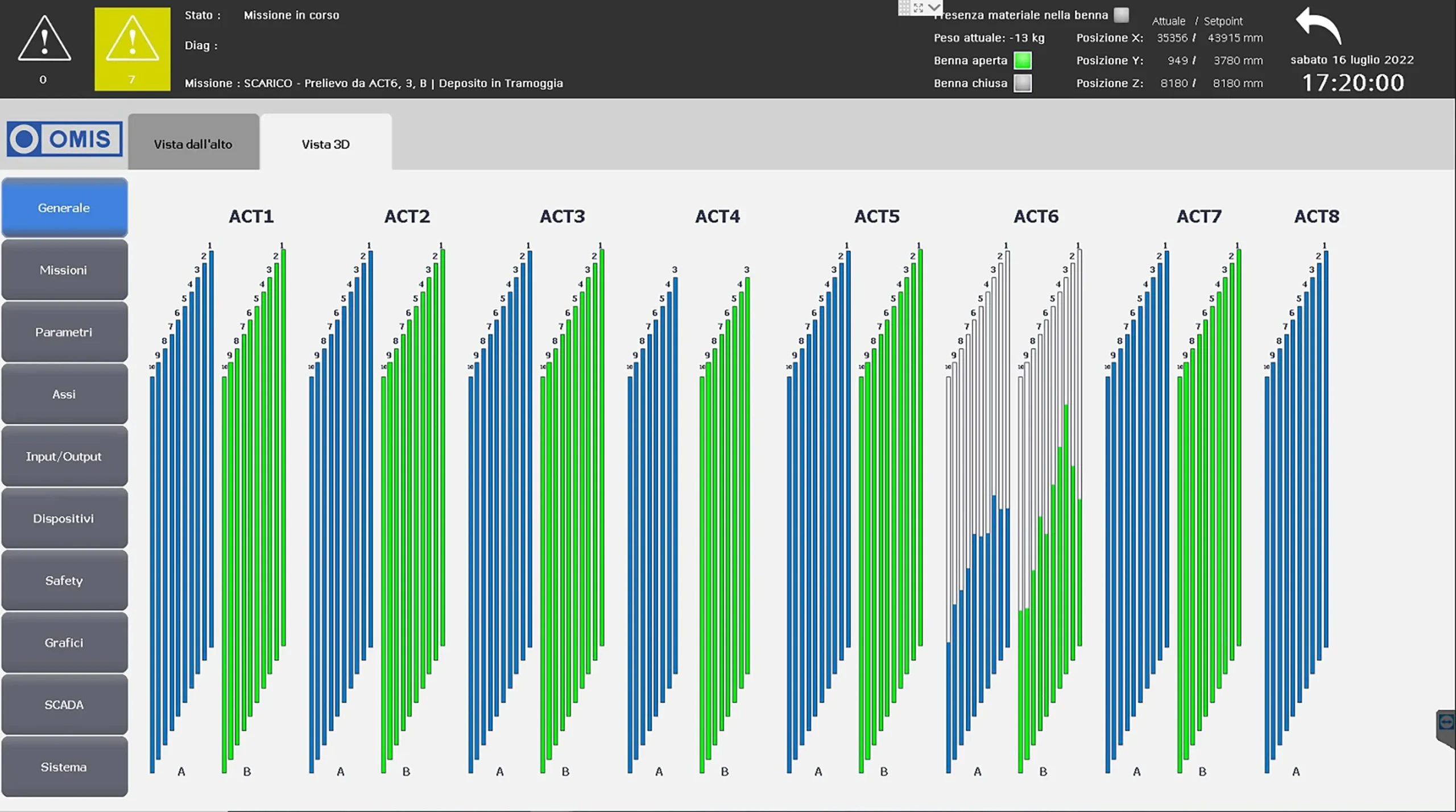

Full-automatic mode: the crane, using sensors and a special interface, detects the presence and quantity of the material below it, foreseeing and executing in continuous mode, without the need for instructions, levelling inside the bunker, or supply to hoppers, shredders, furnaces.

Technology / Software

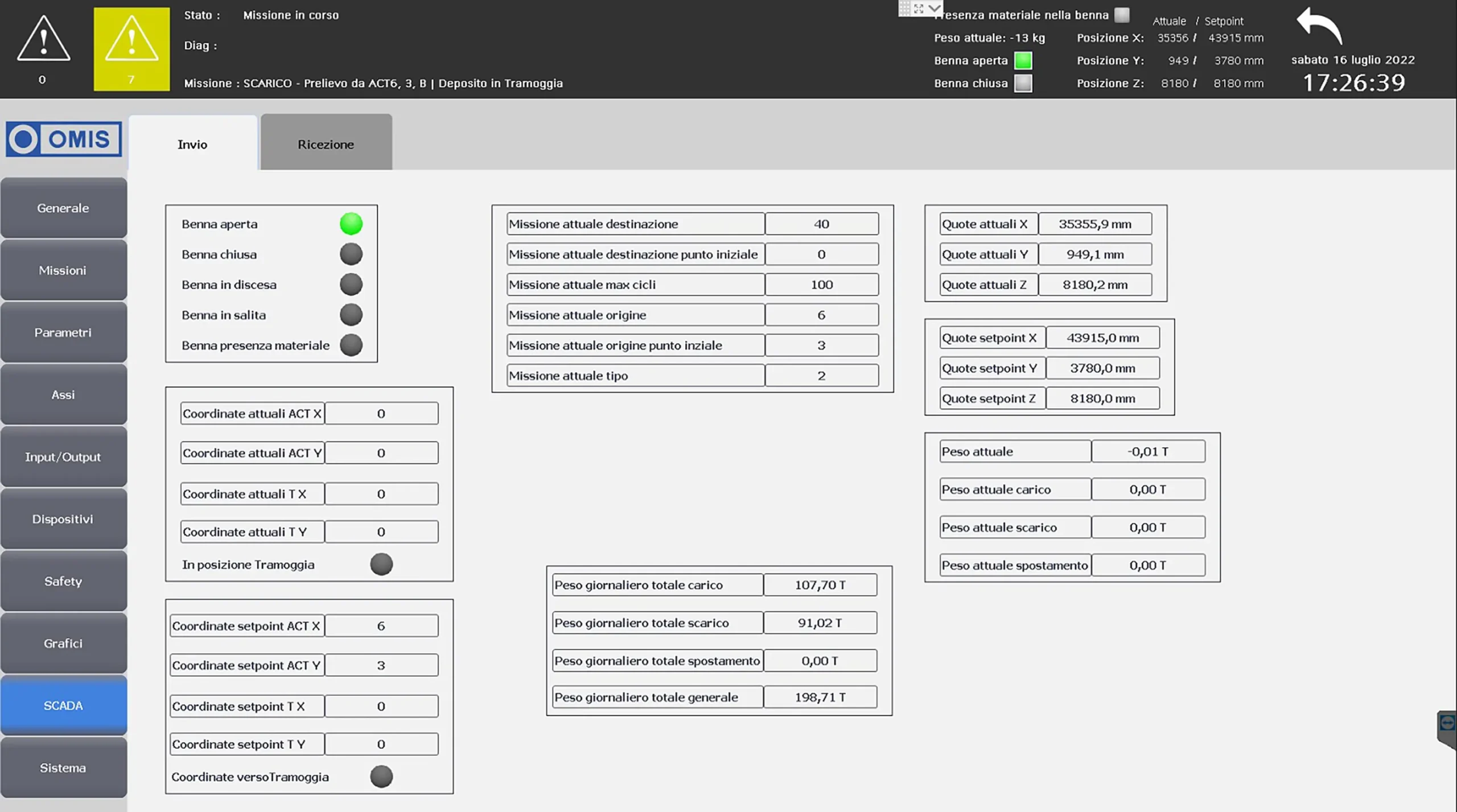

Automation solutions include control and command via the latest generation safety PLCs and supervision via specially developed HMIs, facilitating mission setting, diagnostics, parameterisation and event logging. The system can also interface with management and SCADA systems in the plant to share information on operation.

Monitoring

Dedicated storage strategies ensure that waste is continuously tracked and moved to the treatment lines. Monitoring tools verify processes and plant status, providing a simple and easily understood overview.

Low consumption

If required, special technical measures can keep energy consumption low. The power regenerated by individual movements can be used by the remaining crane motors, while the excess power is fed back into the grid. This results in significant energy savings compared to what is consumed by a standard overhead crane.

Non stop 24/7

Most disposal and recycling plants operate in a continuous cycle. Cranes, therefore, have to operate without breaks. The right machine, supported by a capable maintenance provider, minimises unplanned downtime and ensures efficient and safe operations. Cranes can be fully customised to meet the specific needs of each customer.

Components and services

Picture Gallery

Born to innovate.

Raised to increase values.

OMIS is a manufacturer of excellence, a safe and reliable partner, a group that seeks and practices responsibility and sustainability. Technology, dialogue, sound principles and a forward-looking outlook fuel strategies, industrial approach and environmental awareness.