Efficient error-free logistics even in large spaces

A 4-storey automatic storage unit, 13 mobile racks and 420 containers of more than 4 tonnes, for storing and handling goods of all sizes.

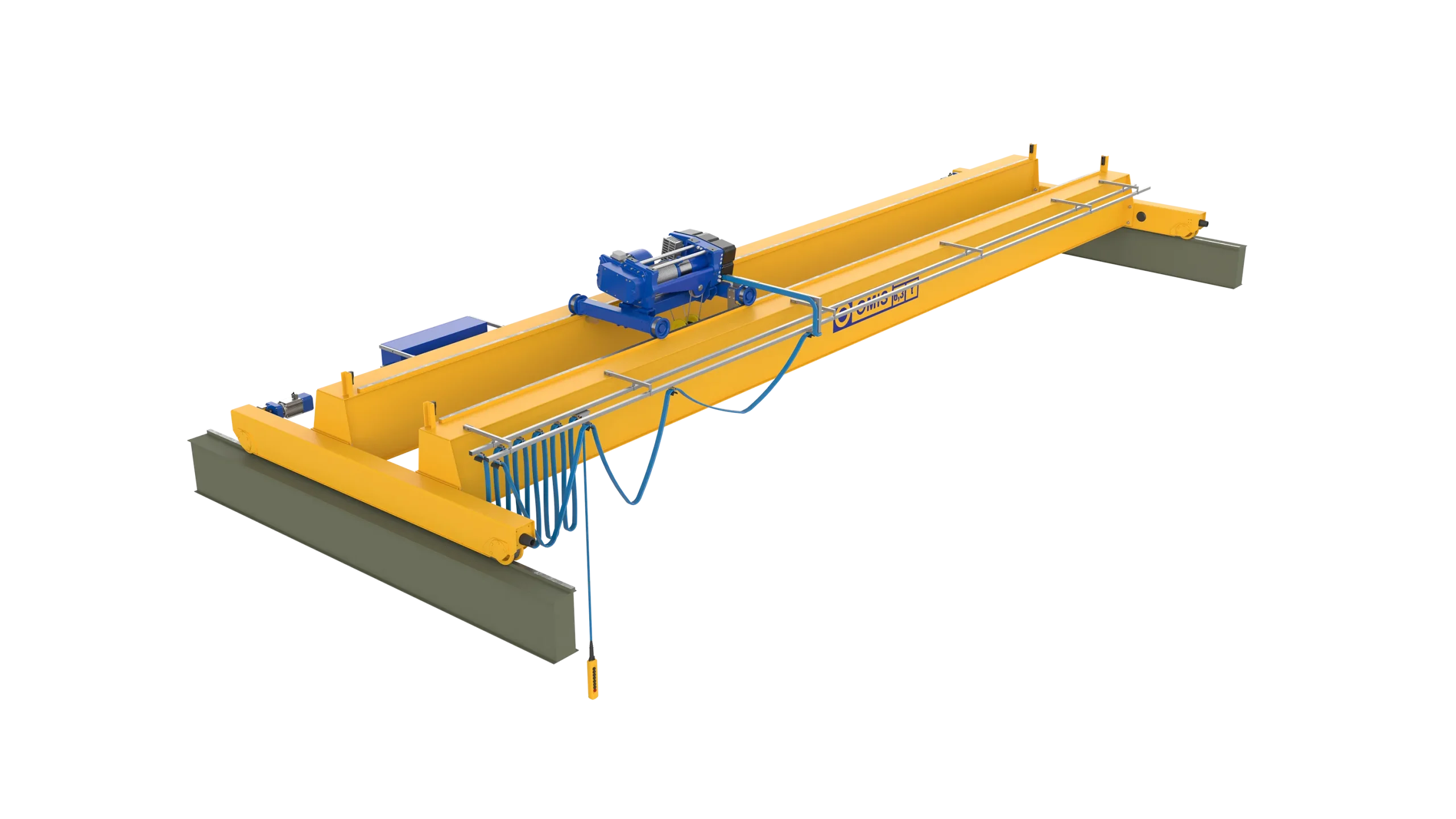

A long-lasting partnership, trust that does not disappoint. Berti Macchine Agricole has been relying on OMIS for more than twenty years to lift materials and products safely and efficiently, with the certainty of receiving excellent service even after purchase, thanks to careful assistance throughout the entire service life of the equipment. The company’s new requirement was to concentrate the warehouse in a single location, using optimised logistics, in a large building with a height of 13 metres and the need for large capacities. The installation of an automatic overhead crane, combined with a mobile racking system, was a winning choice that allowed the optimisation of space, making picking operations more accurate and error-free.

Two interconnected shuttles and accurate automatic tracking.

13 mobile racks, 4 storeys high, 420 4.5 tonne containers: this was not an easy challenge, nor one you encounter every day. A great deal of effort went into the engineering design to achieve a fundamental asset for improving warehouse efficiency and internal logistics. The handling of goods, carefully planned, is tracked at every stage of the production cycle and strategically optimised to store and handle material of all weights and sizes, making the most of the available space. Objects are identified using vision systems, sensors and optical readers that accurately recognise the type and quantity of parts to be moved. The addition of two shuttles interconnected to the system allows for accurate and fully automated loading and unloading of material within the departments. A truly “successful” system, with a total capacity of 1,800 tonnes, which among other things allows a certain “ecological” saving by drastically reducing the number of trucks at work.