The paint colour can be customised to meet specific needs, design or branding requirements.

125kg

5000kg

10m

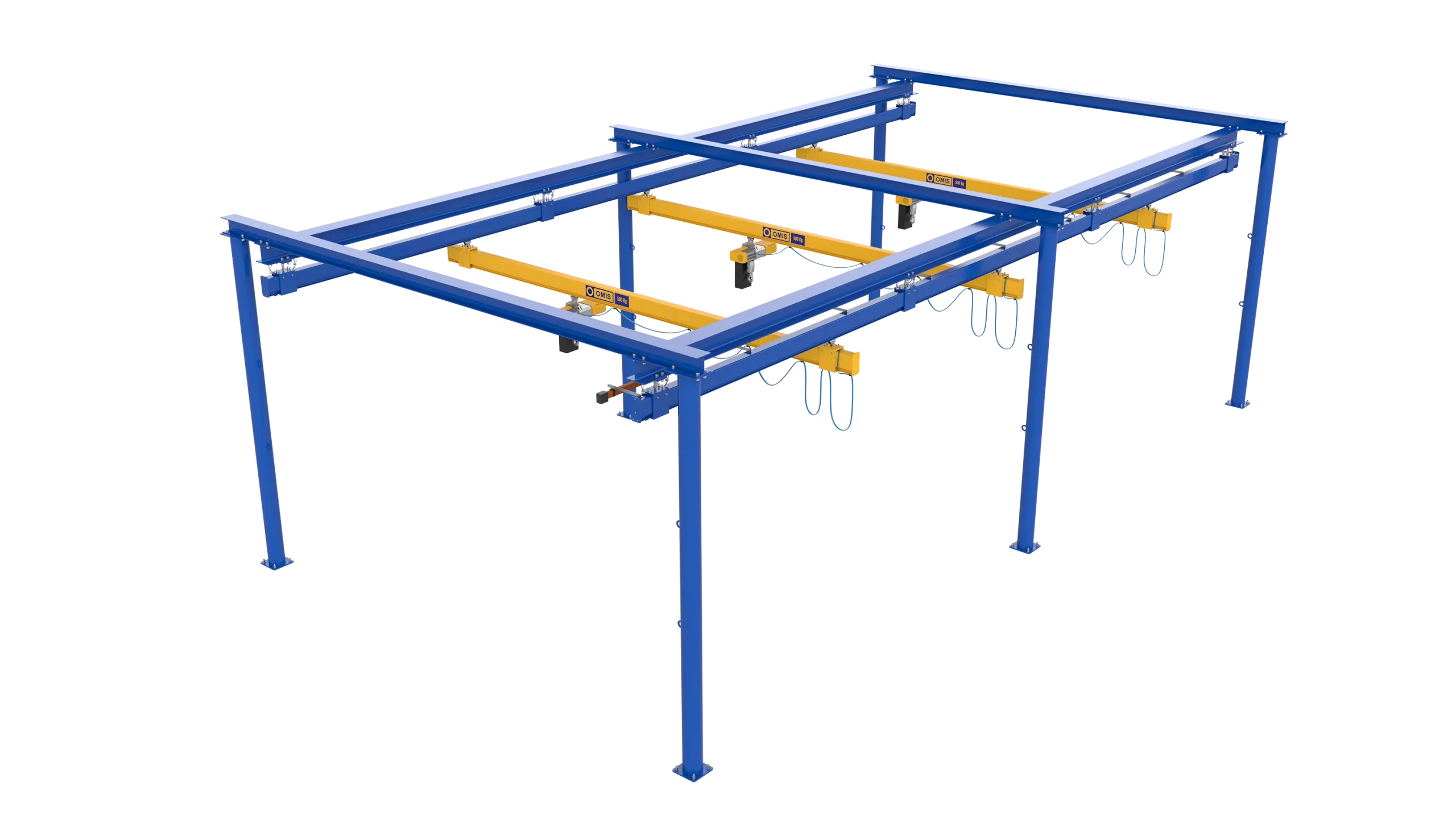

Powered suspended systems with capacity up to 5000 kg

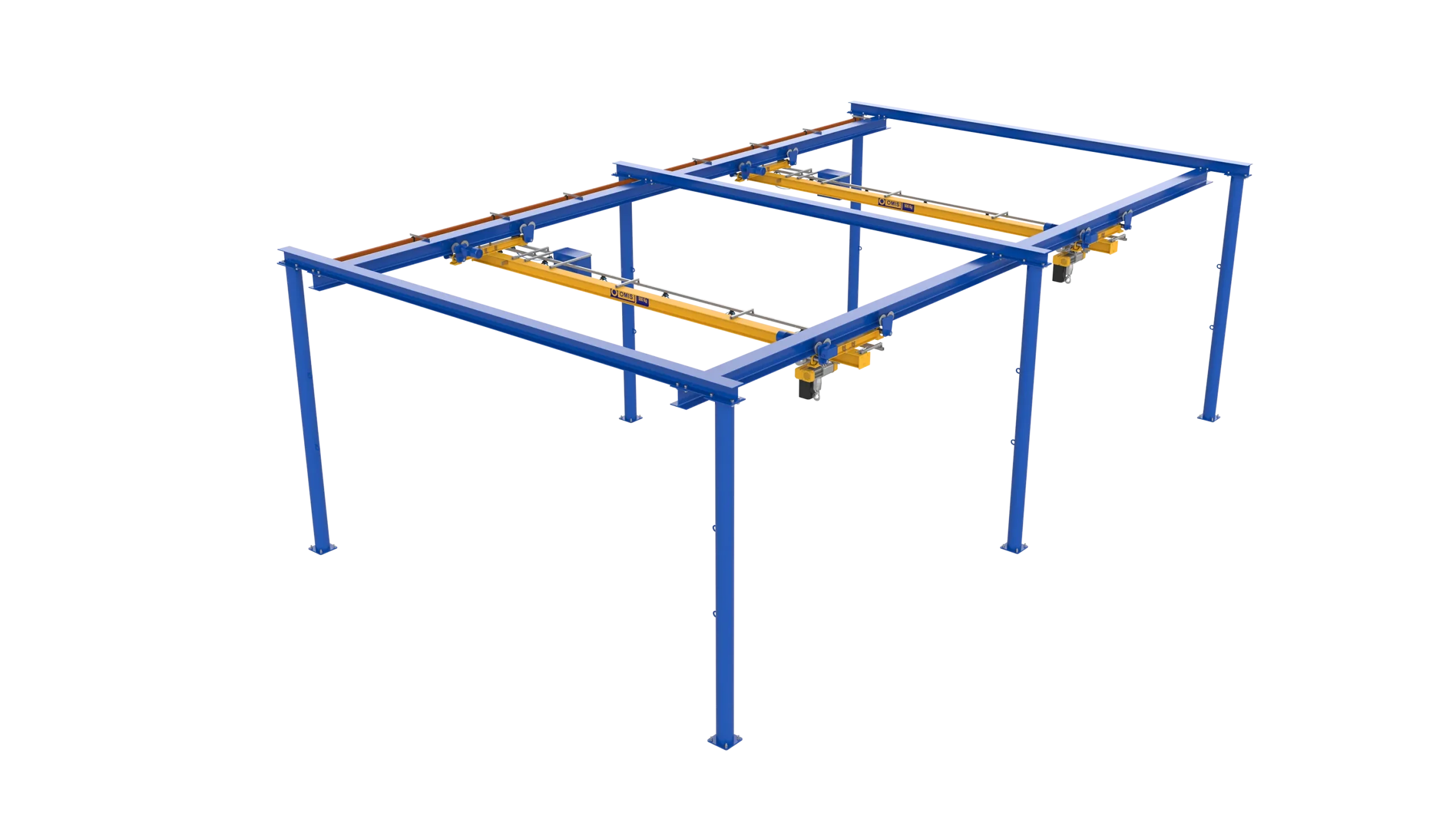

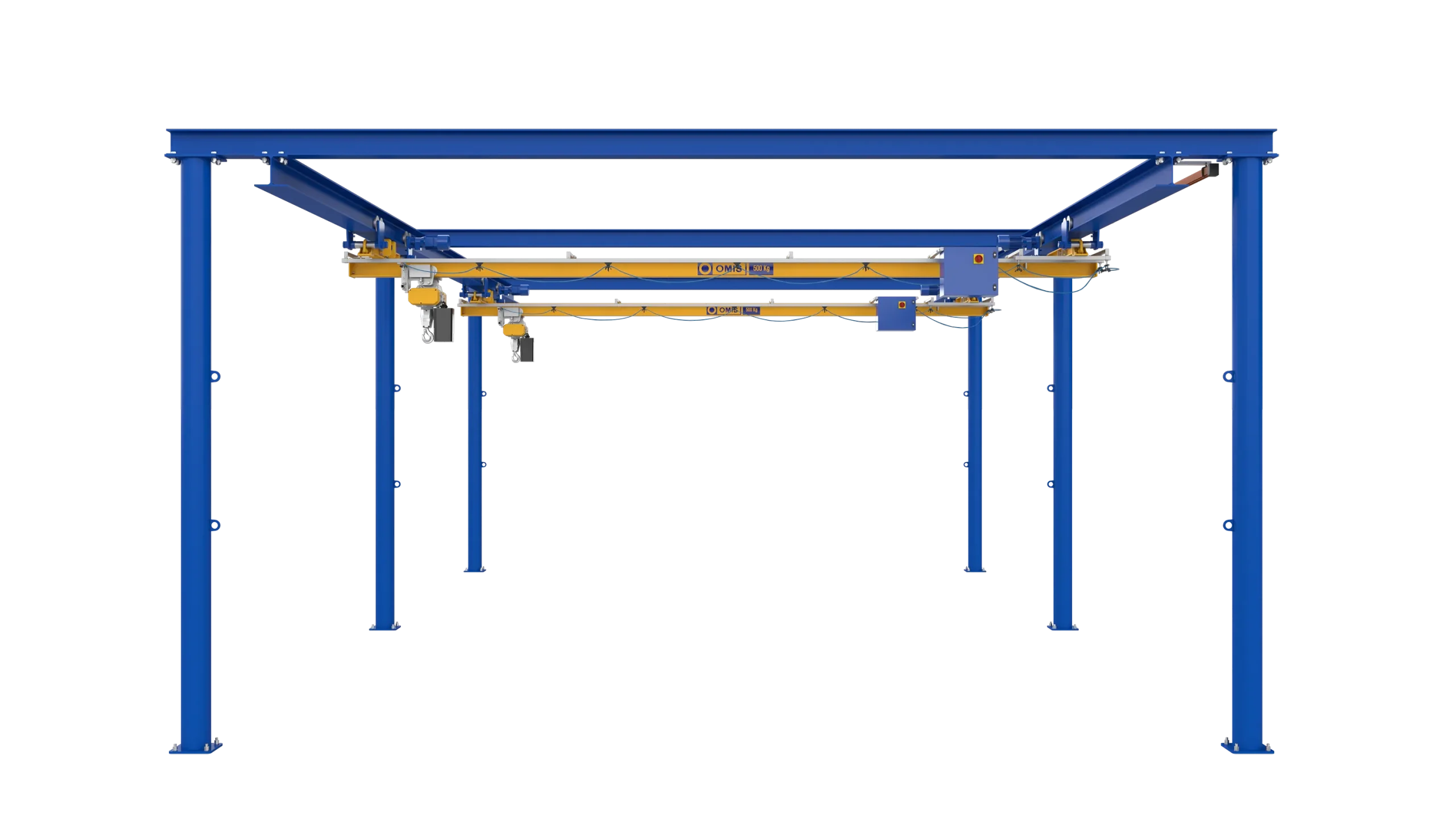

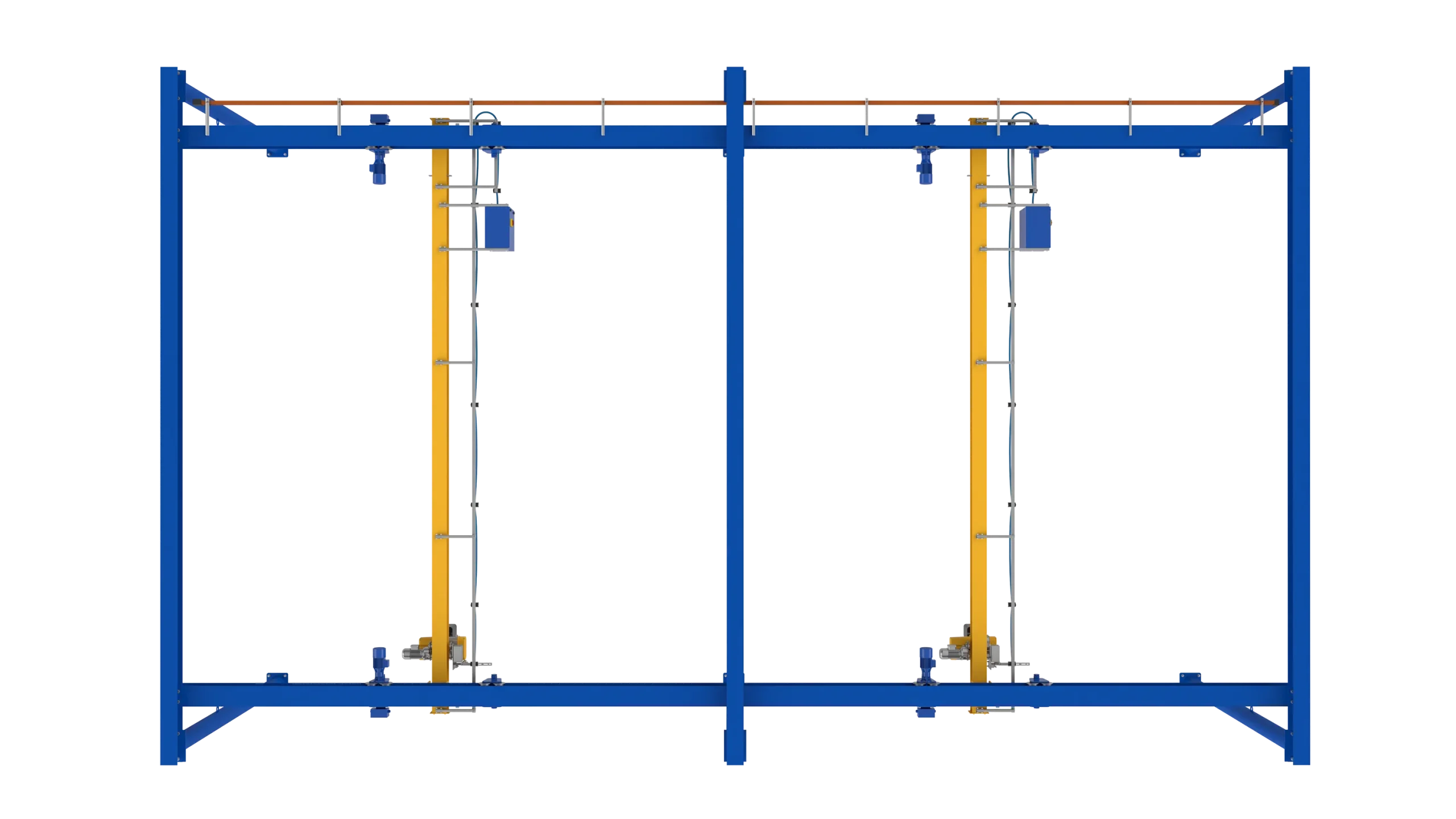

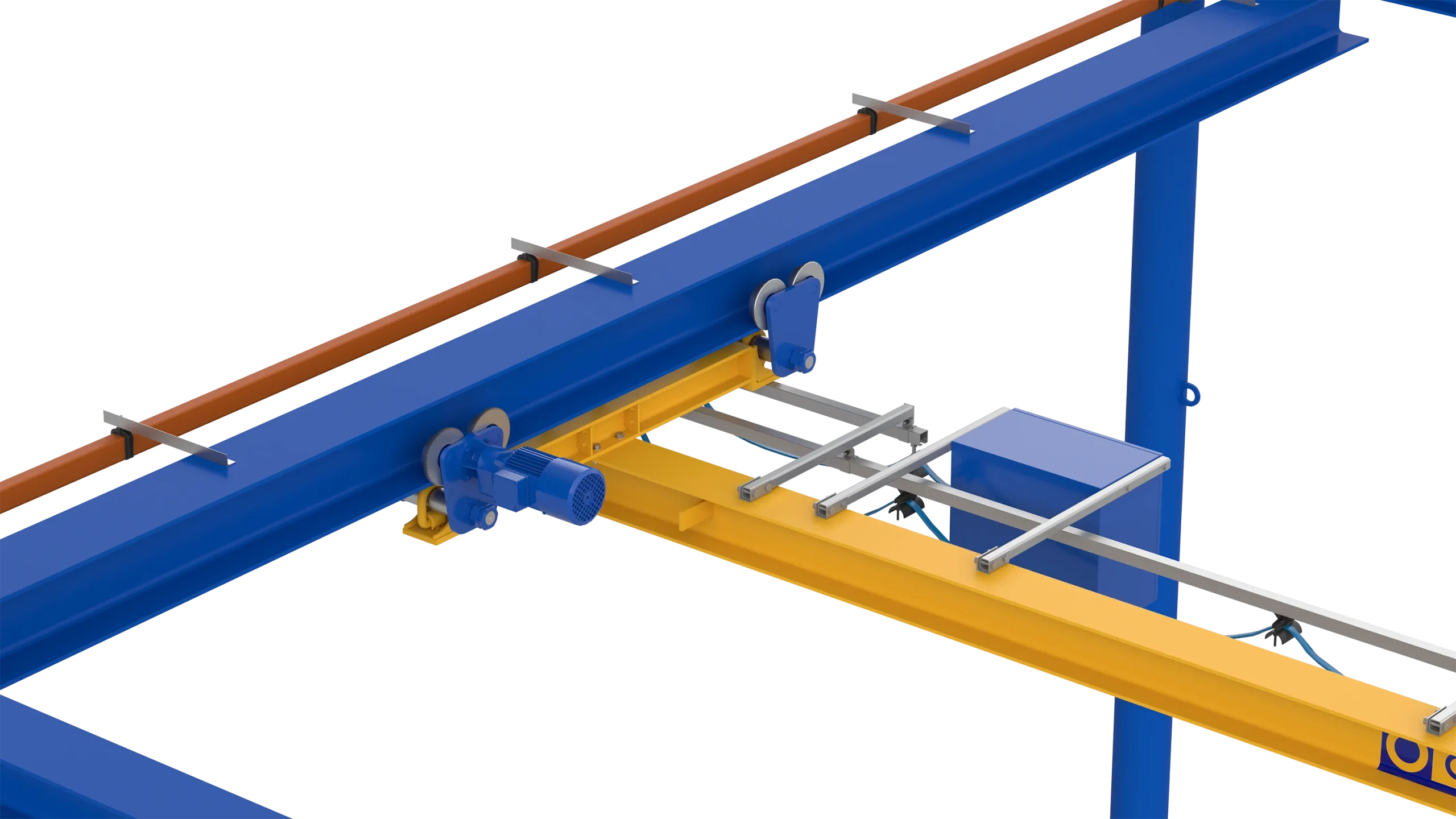

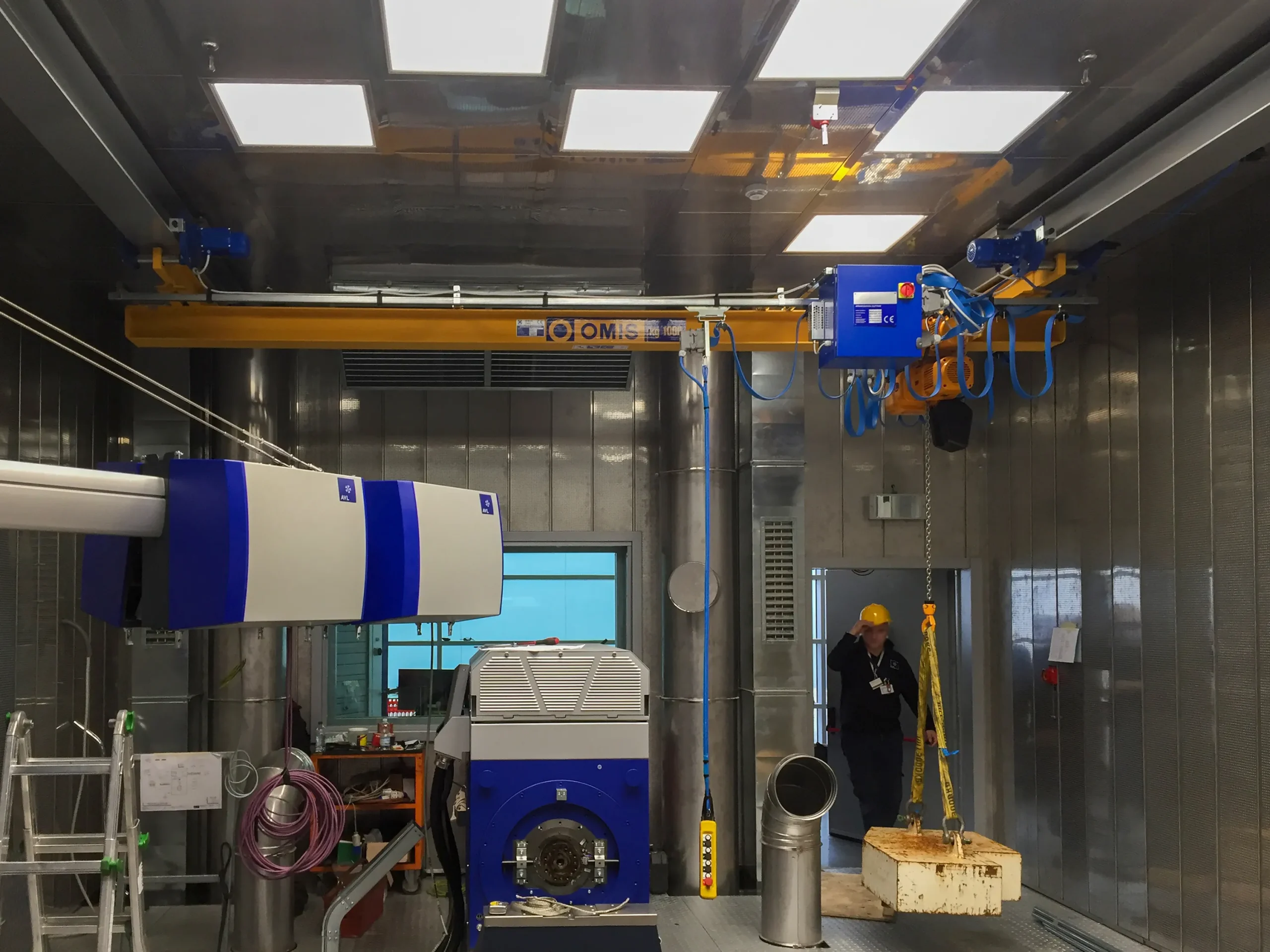

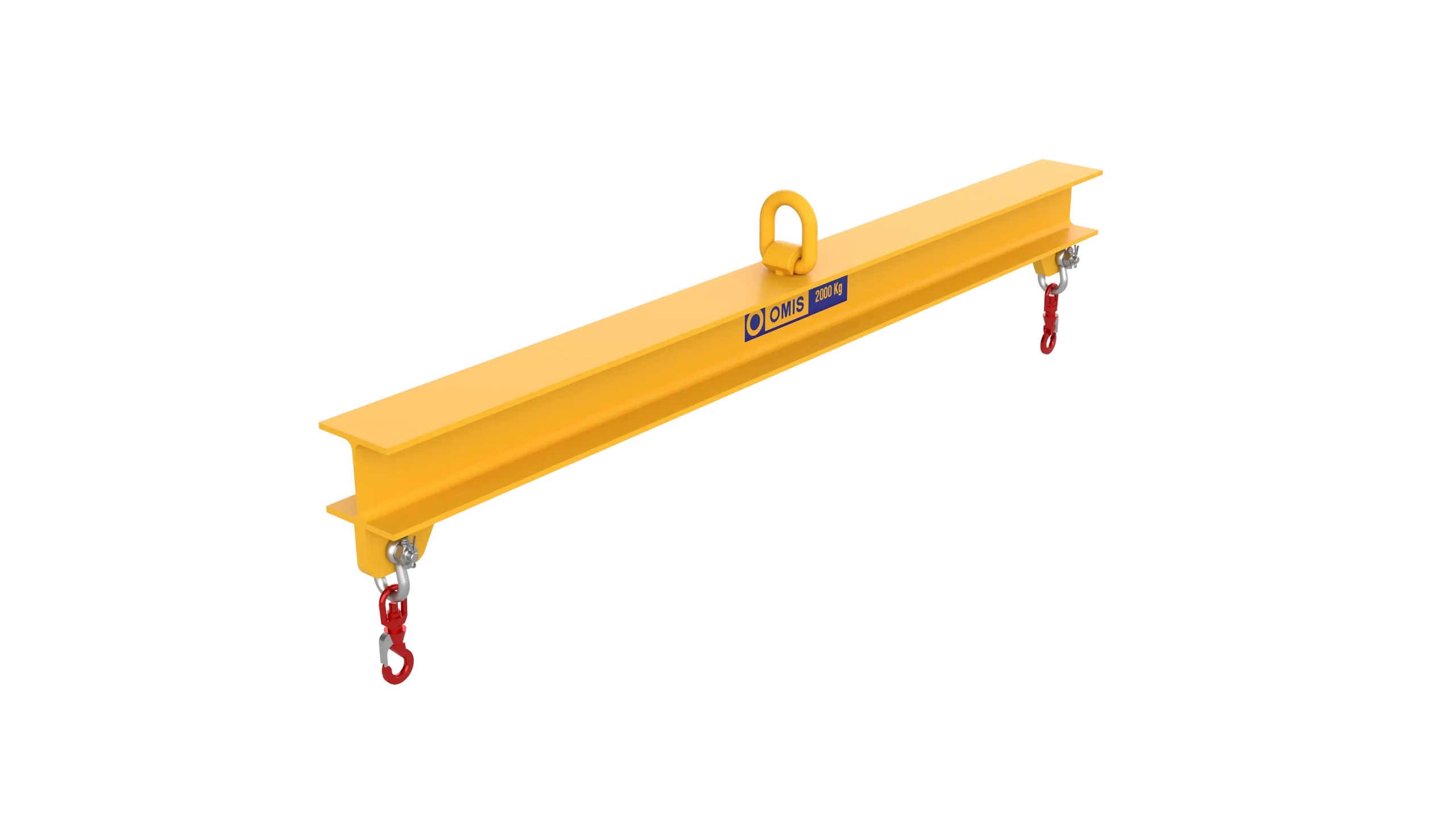

OMIS designs and manufactures suspended lifting systems with laminated I-beam runways for powered sliding of the bridge. The crane is powered along the overhead runways, thus leaving the floor area free and available for production activities.

The single-girder suspended system is designed to move goods within a production plant or on assembly lines. The powered suspended electric crane lifts loads vertically and moves them sideways and lengthways using the trolley and the powered end carriages of the bridge. The great advantage of this type of lifting equipment for daily productivity is precisely the ability to operate effectively and precisely, in extreme safety, without interfering with the ordinary and extraordinary work of employees and machinery within the perimeter of the production unit, facilitating efficiency and saving time and space.

Advantages of the powered suspended crane

Custom paintwork

Custom metal support structures

On request, custom metal support structures or custom solutions can be designed, ensuring that each specific requirement is met with precision and quality.

Box girder runways

In the case of high load capacities, box girder runways can be designed and constructed on request for greater reliability. These structures offer superior strength and resistance to deformation under heavy loads, ensuring greater stability and durability.

Inverter-controlled sliding and travel

The inverter-controlled sliding and travel system ensures smooth and precise movements, optimising control and operational efficiency.

Radio control or independent push-button strip

The system with radio control or independent push-button strip provides versatile and intuitive control, improving safety and efficiency in operations. Ideal for dynamic environments, it allows smooth operation and adaptability to different needs.

Picture Gallery

OMIS Service

Emergency response and scheduled maintenance. Repairs, upgrades, modifications and checks aimed at assessing residual life.

Born to innovate.

Raised to increase values.

OMIS is a manufacturer of excellence, a safe and reliable partner, a group that seeks and practices responsibility and sustainability. Technology, dialogue, sound principles and a forward-looking outlook fuel strategies, industrial approach and environmental awareness.