The paint colour can be customised to meet specific needs, design or branding requirements.

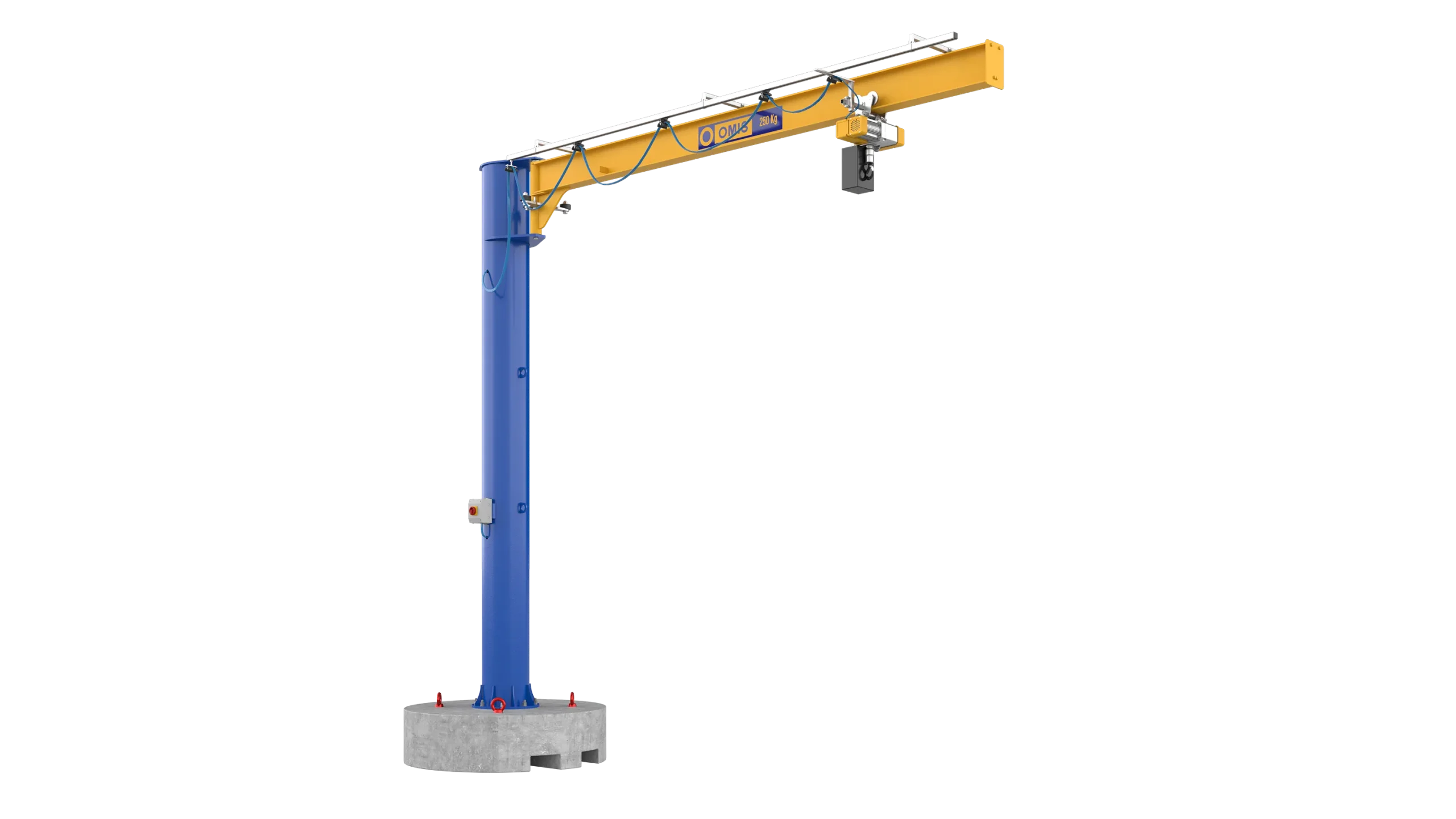

500kg

6m

270°

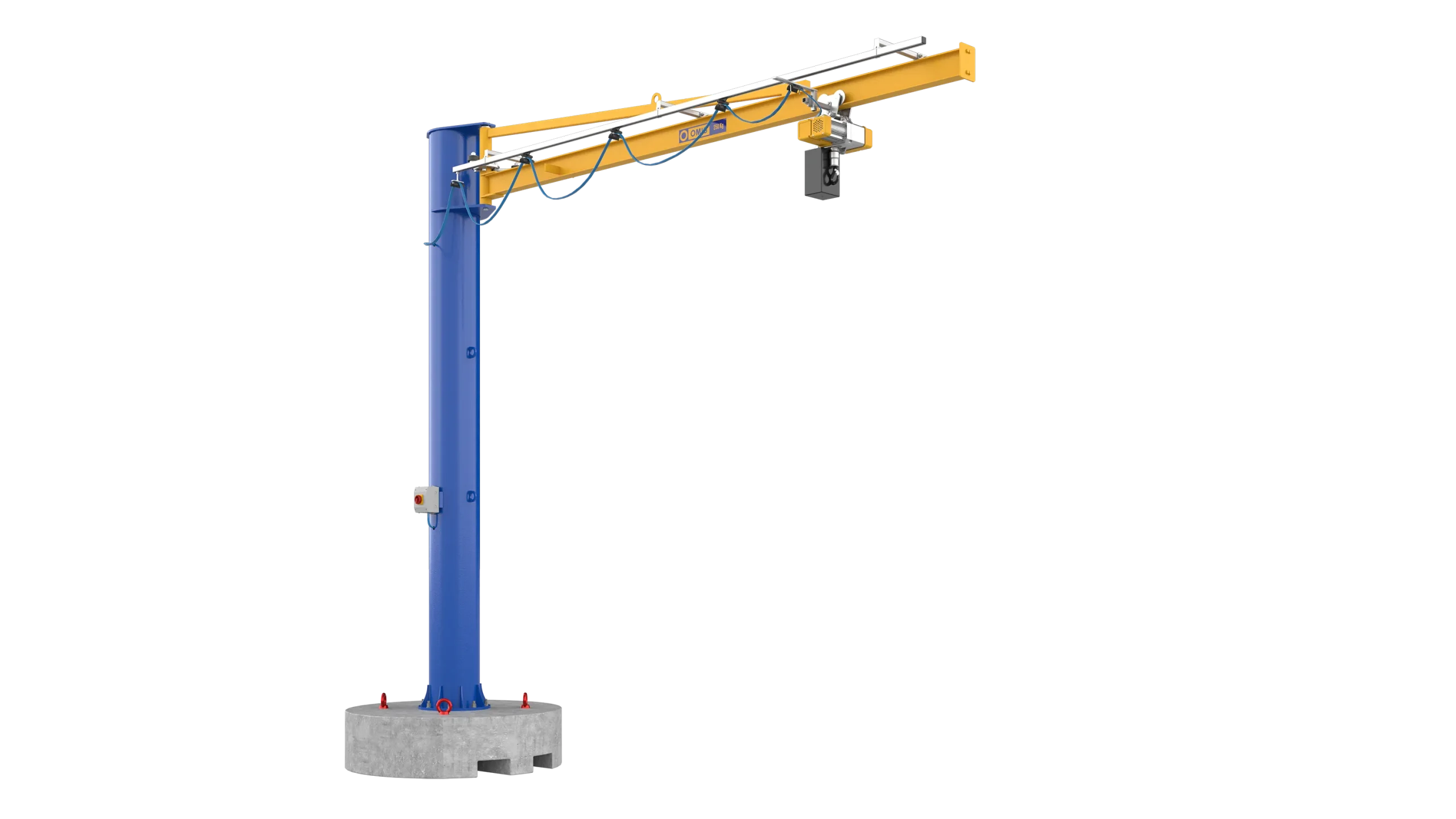

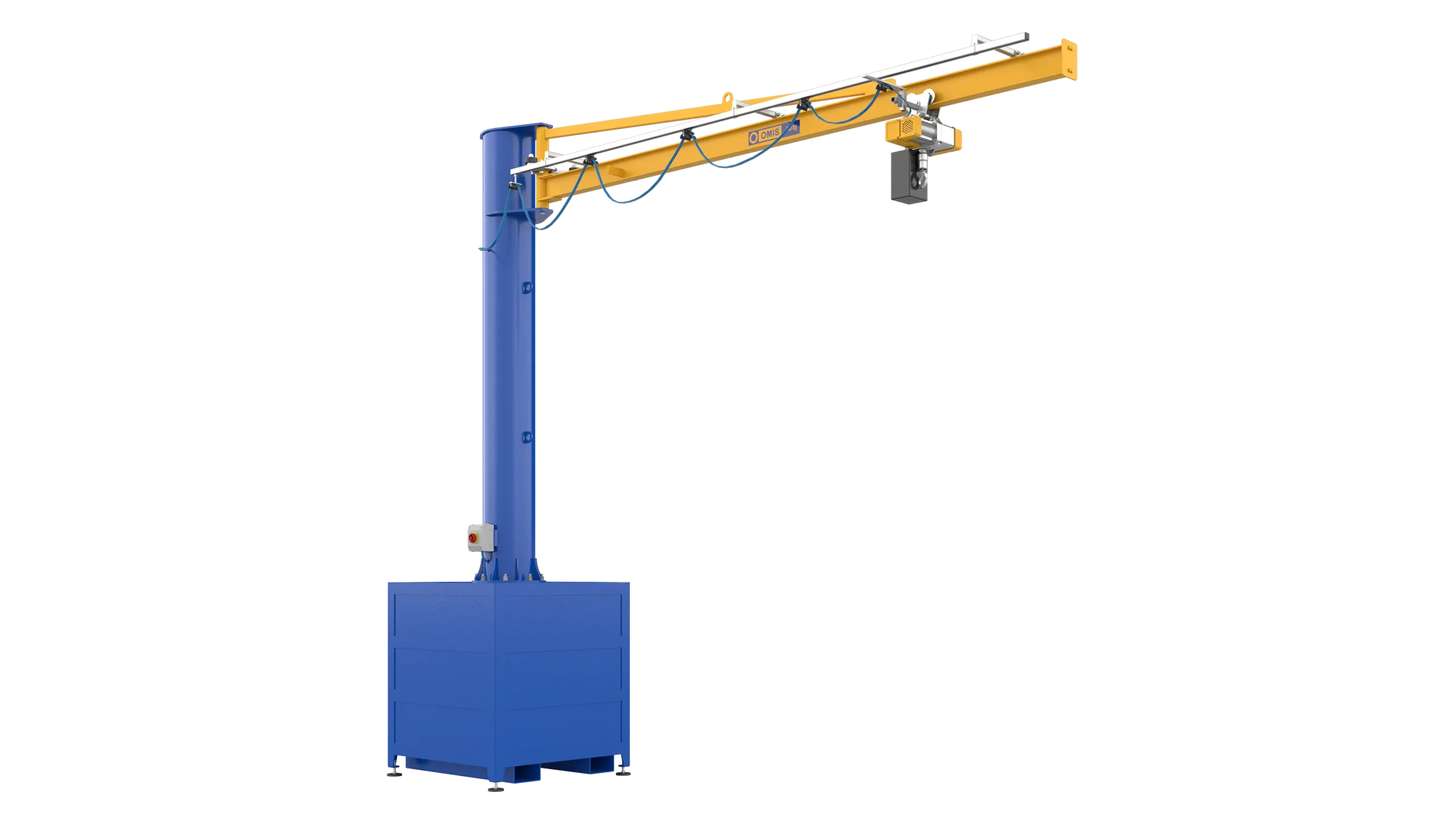

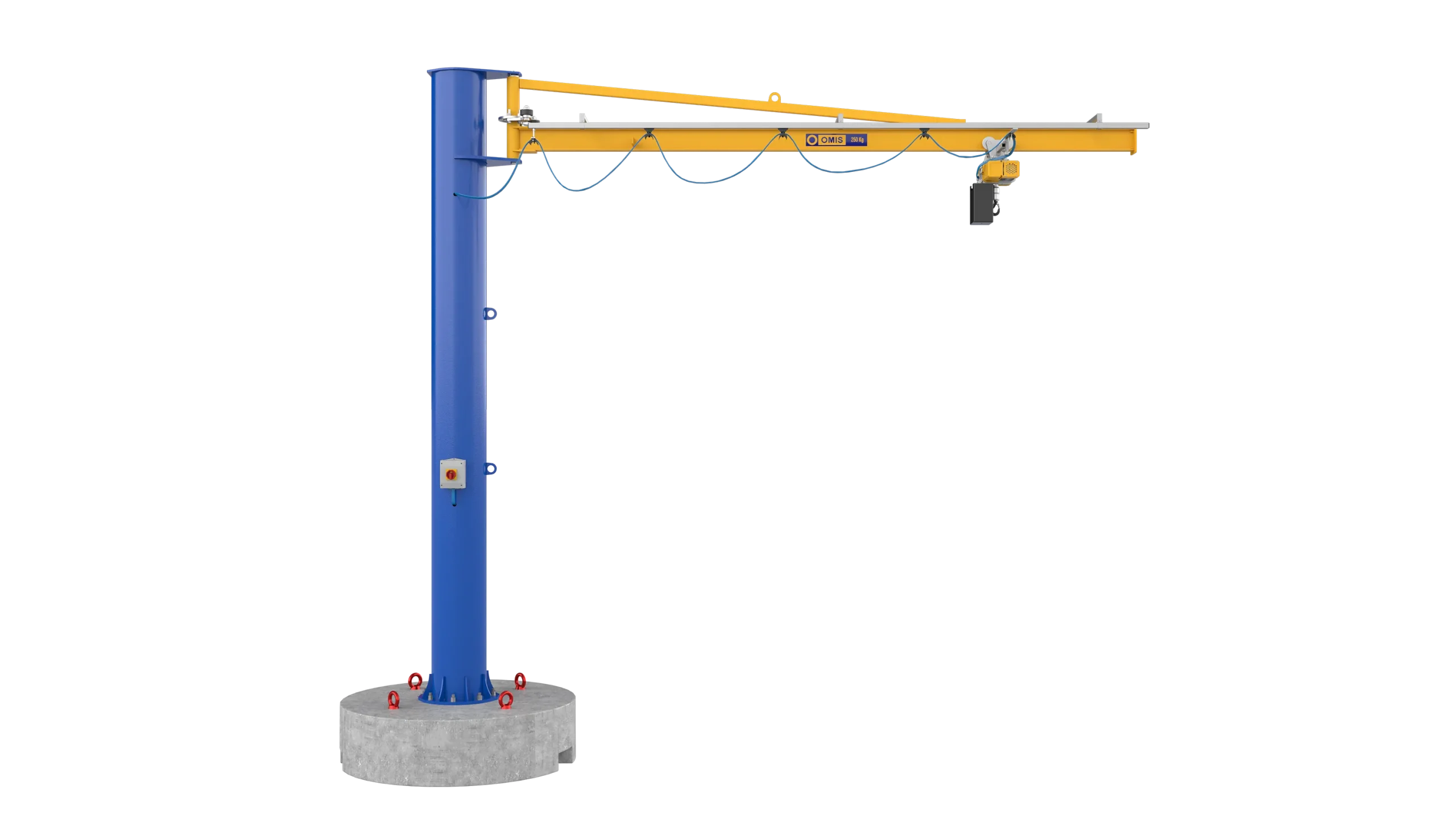

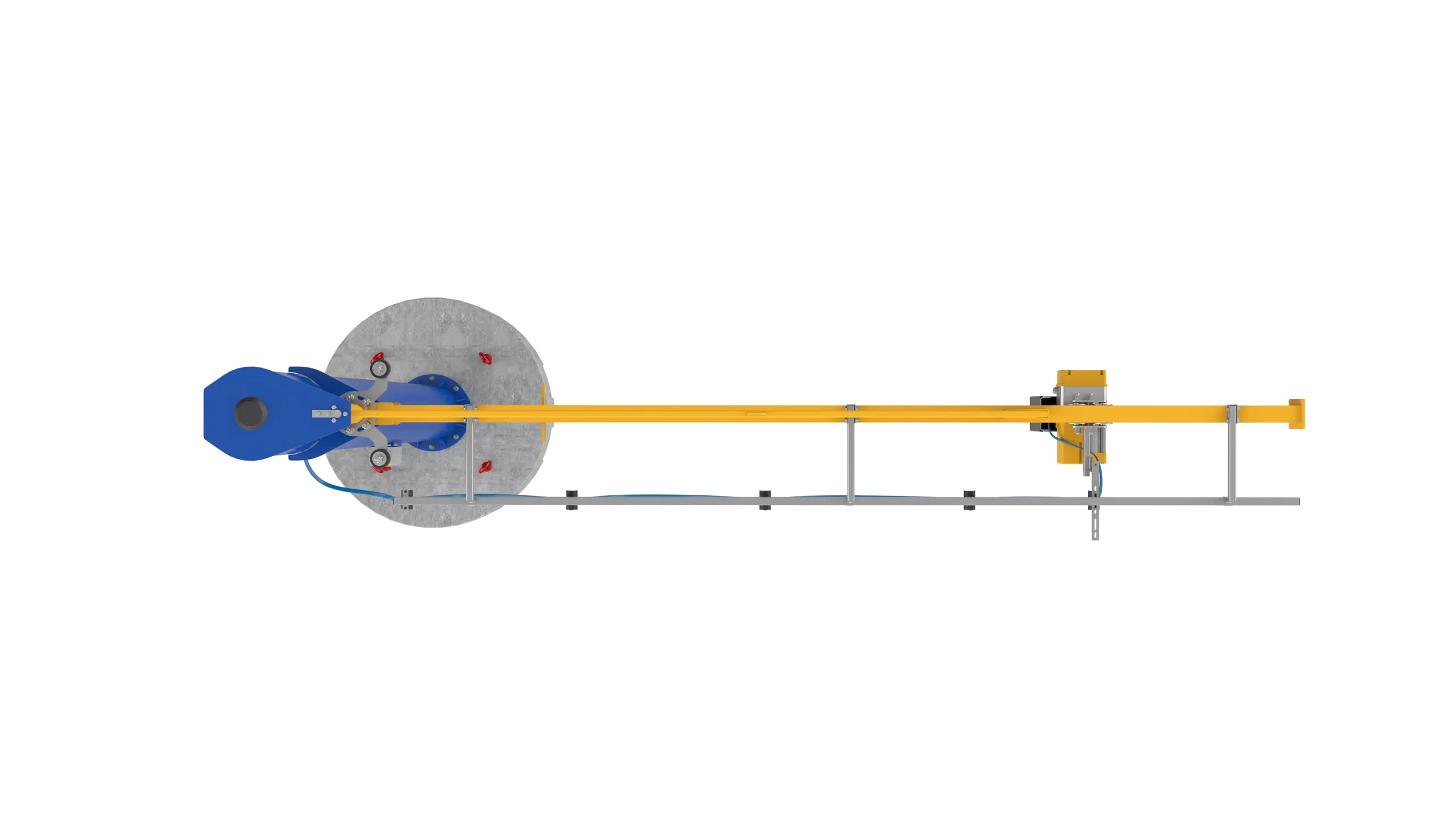

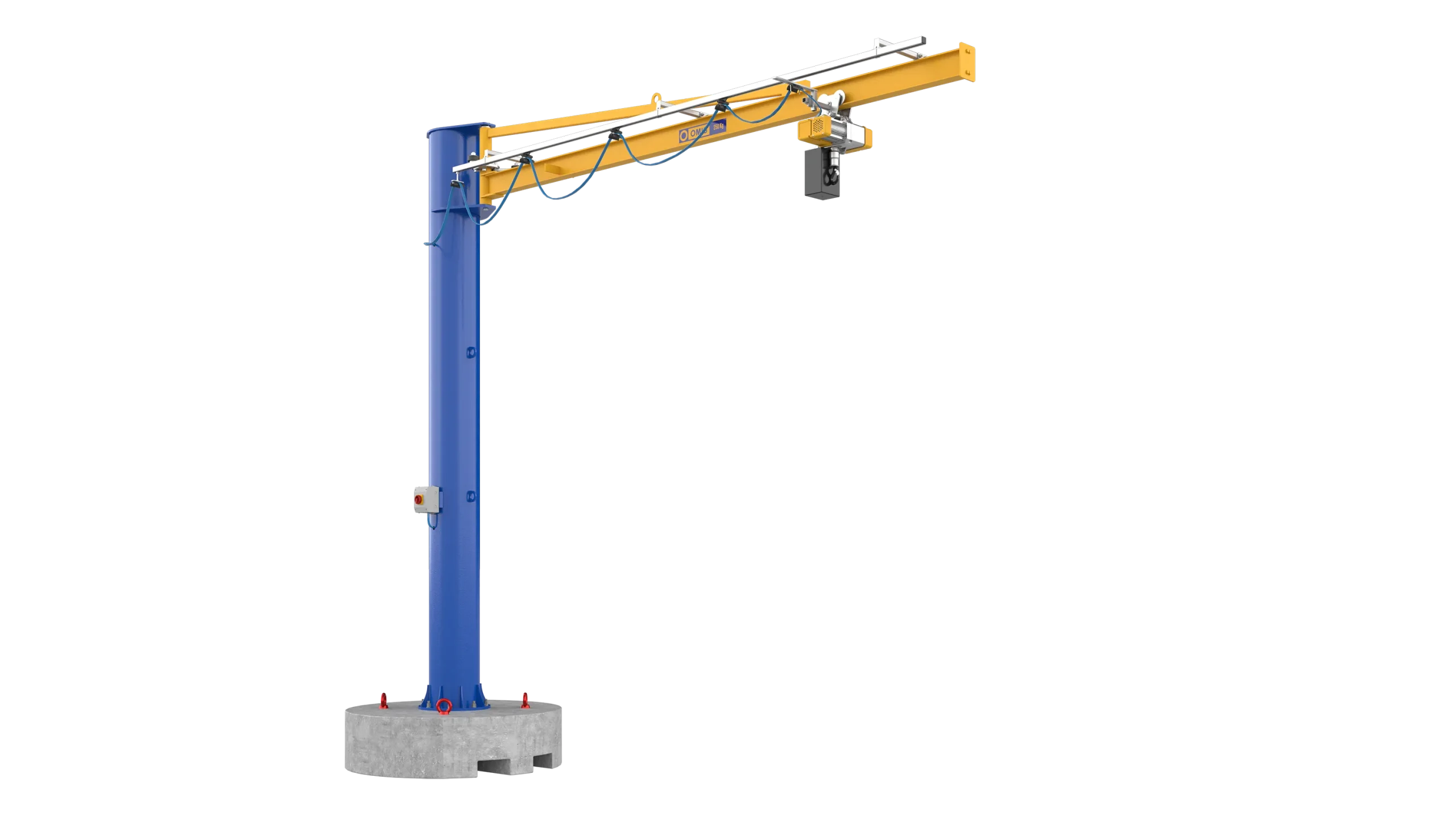

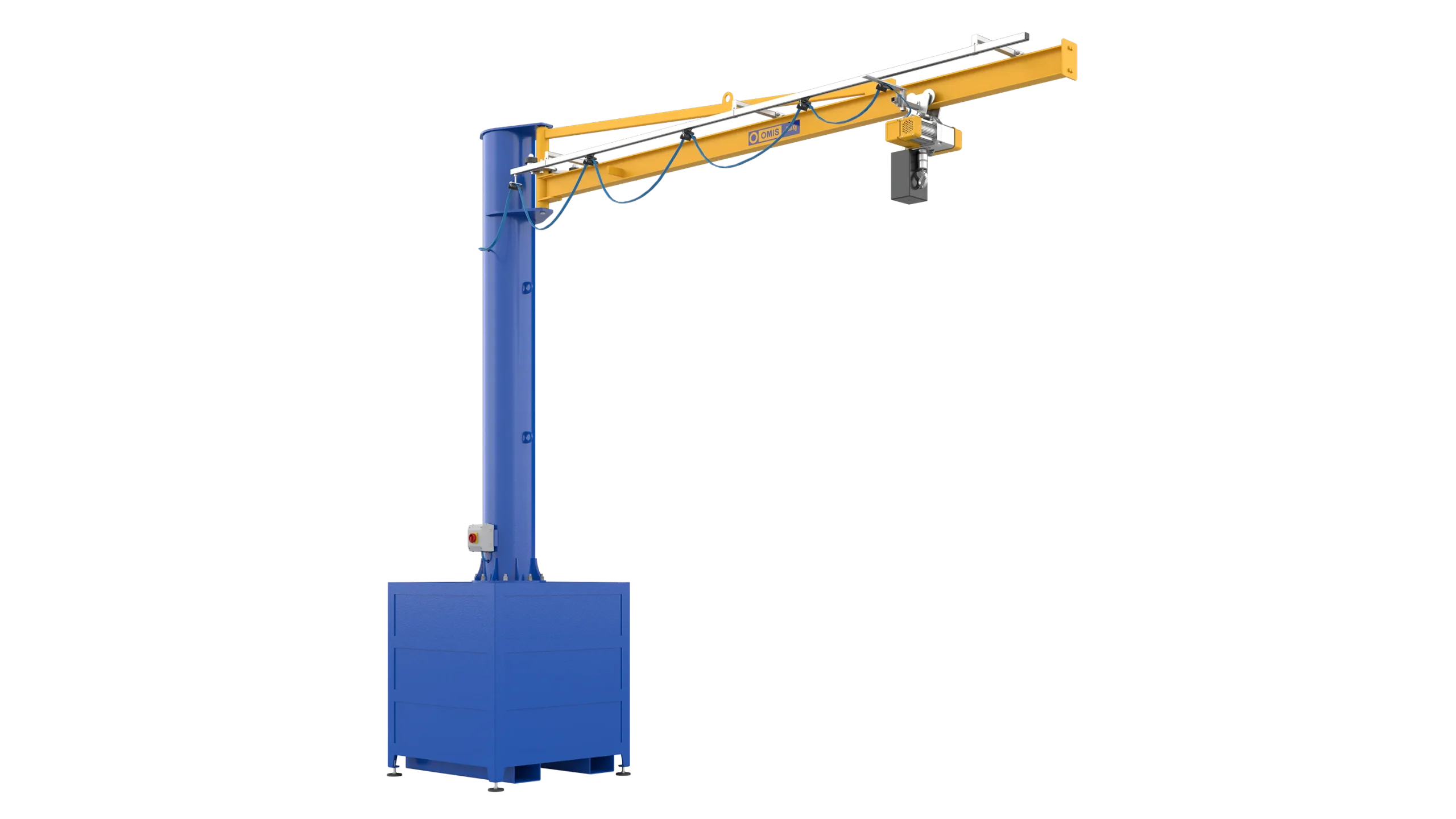

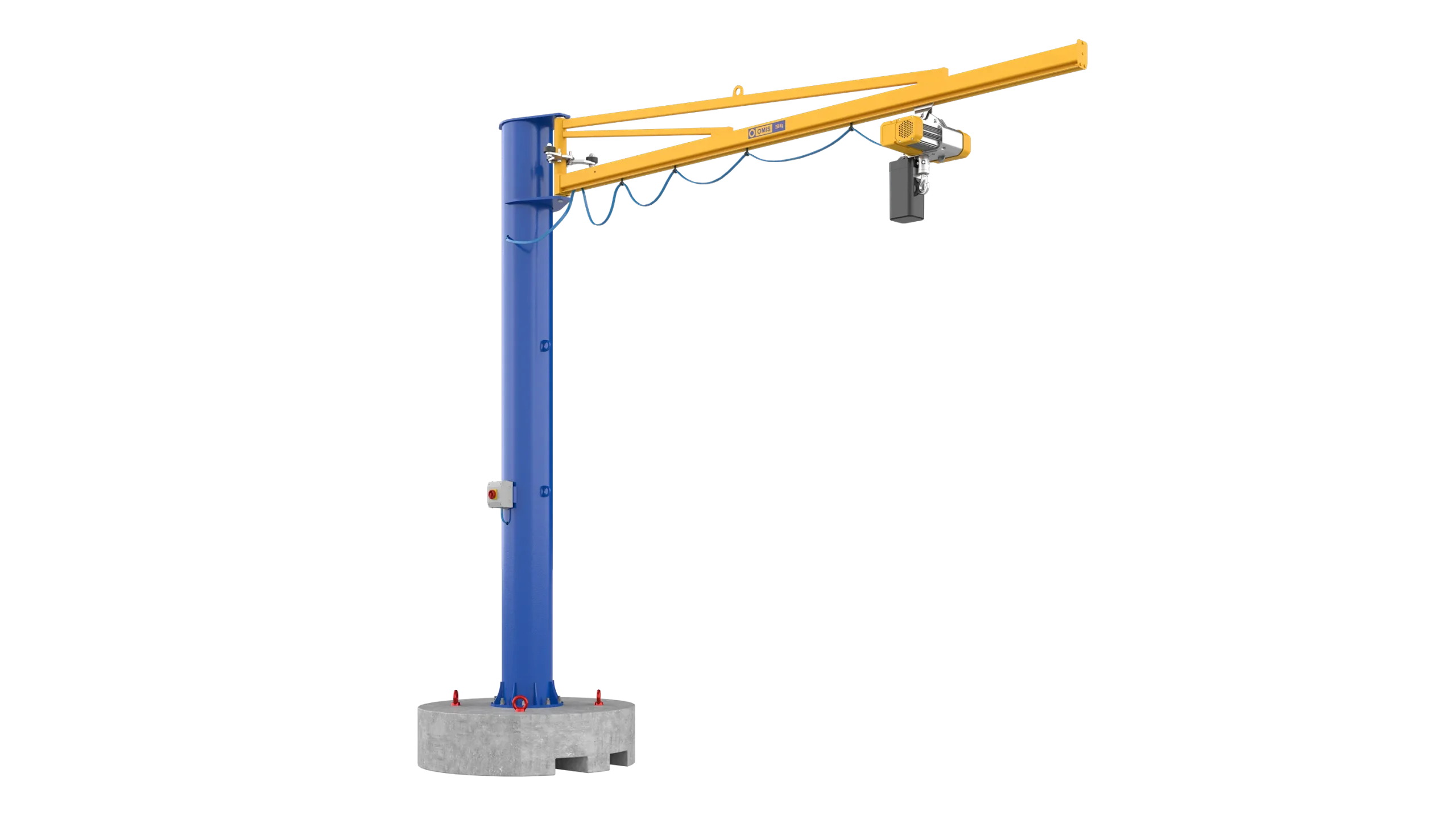

Pillar jib crane with girder boom and tie rods with capacity up to 500 kg

The jib crane on a movable plinth allows operators to shift the crane, using suitable lifting equipment, to more than one location in the factory or construction site, without the constraint of a permanent anchorage to the ground.

Extremely versatile, this type of jib crane combines ease of movement and positioning wherever needed in the working environment with the practicality and economy of use that are the added value of the entire category.

The pillar jib crane with girder boom with tie rods and movable plinth is a solution that, thanks to the use of tie rods, is particularly suitable for higher capacities and extensions, compared to the version with a cantilever girder. Easy to install, it is used for handling light loads in a great many industrial applications, from small workshops to large assembly lines, food production plants or wine cellars.

Advantages of the pillar jib crane with girder boom with tie rods and movable plinth

Custom paintwork

OMIS Service

Emergency response and scheduled maintenance. Repairs, upgrades, modifications and checks aimed at assessing residual life.

Born to innovate.

Raised to increase values.

OMIS is a manufacturer of excellence, a safe and reliable partner, a group that seeks and practices responsibility and sustainability. Technology, dialogue, sound principles and a forward-looking outlook fuel strategies, industrial approach and environmental awareness.