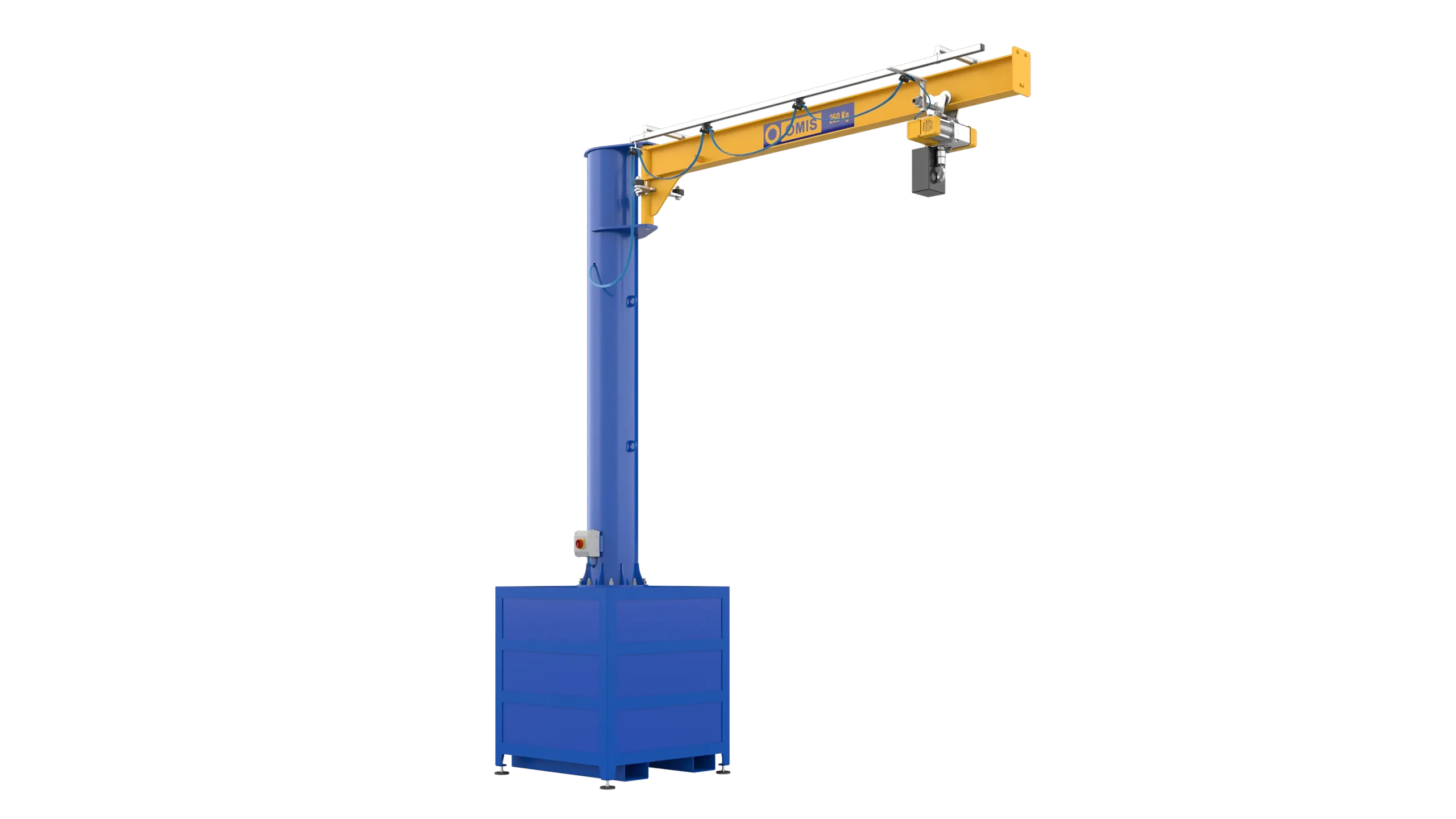

The paint colour can be customised to meet specific needs, design or branding requirements.

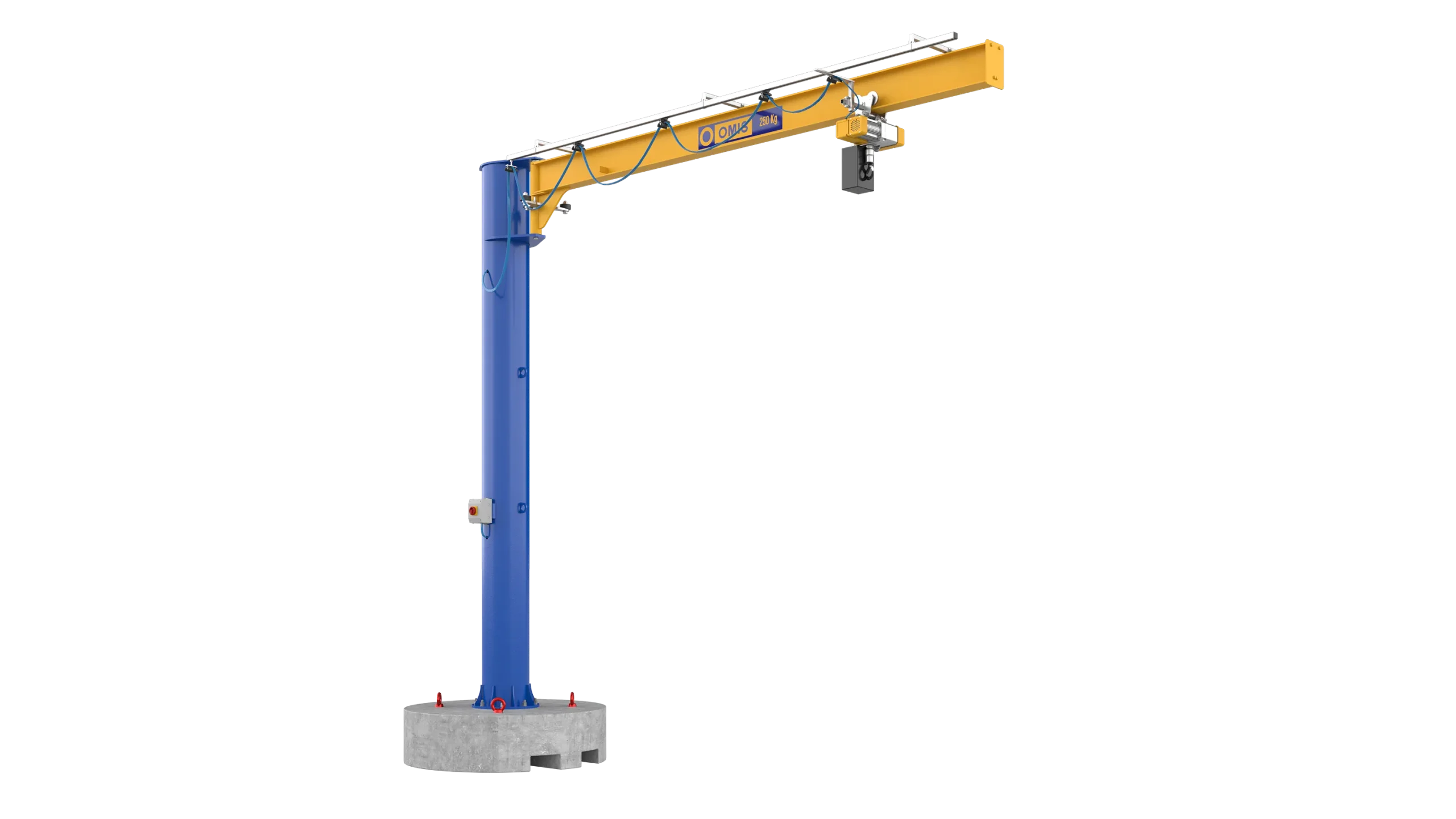

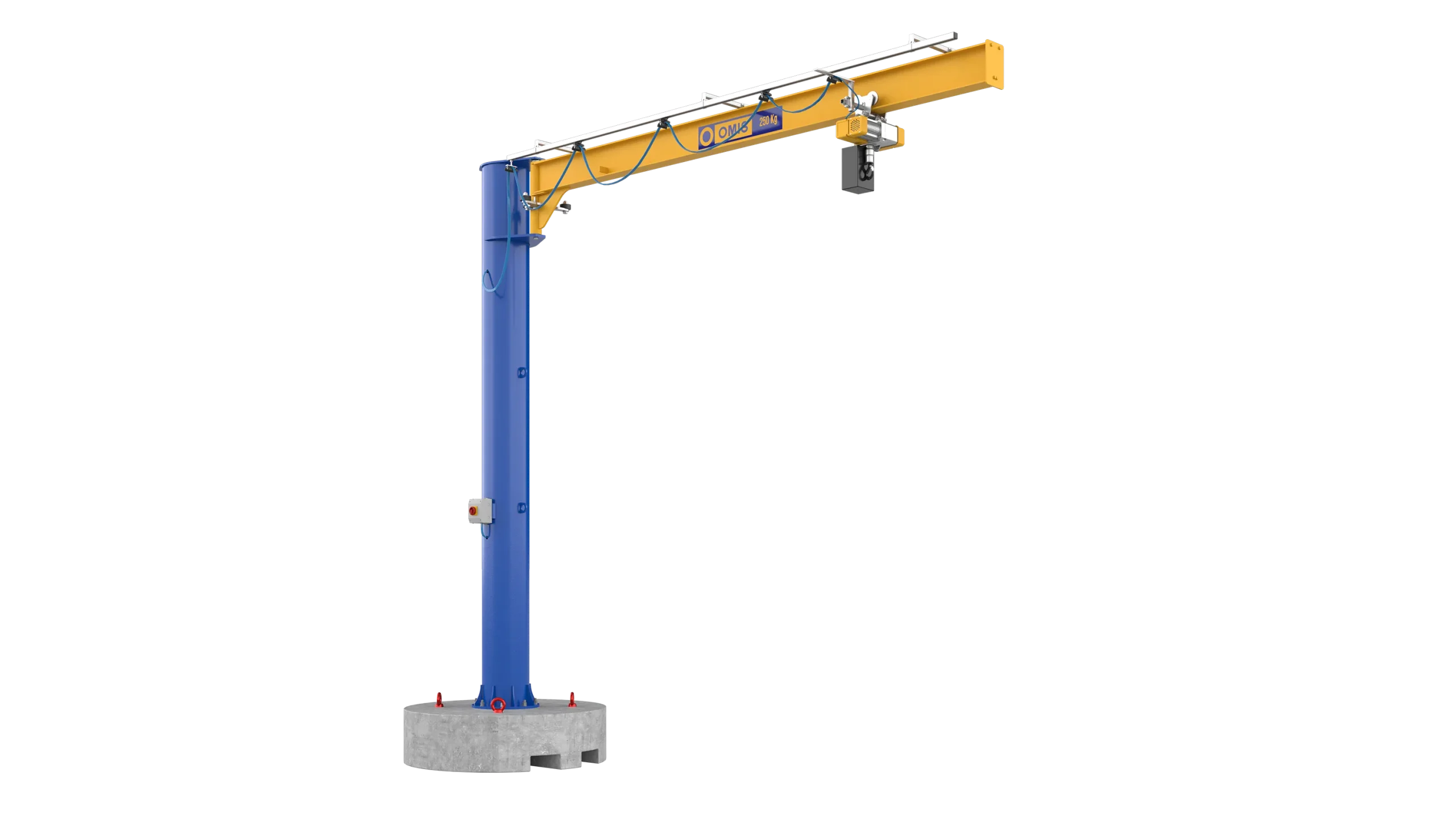

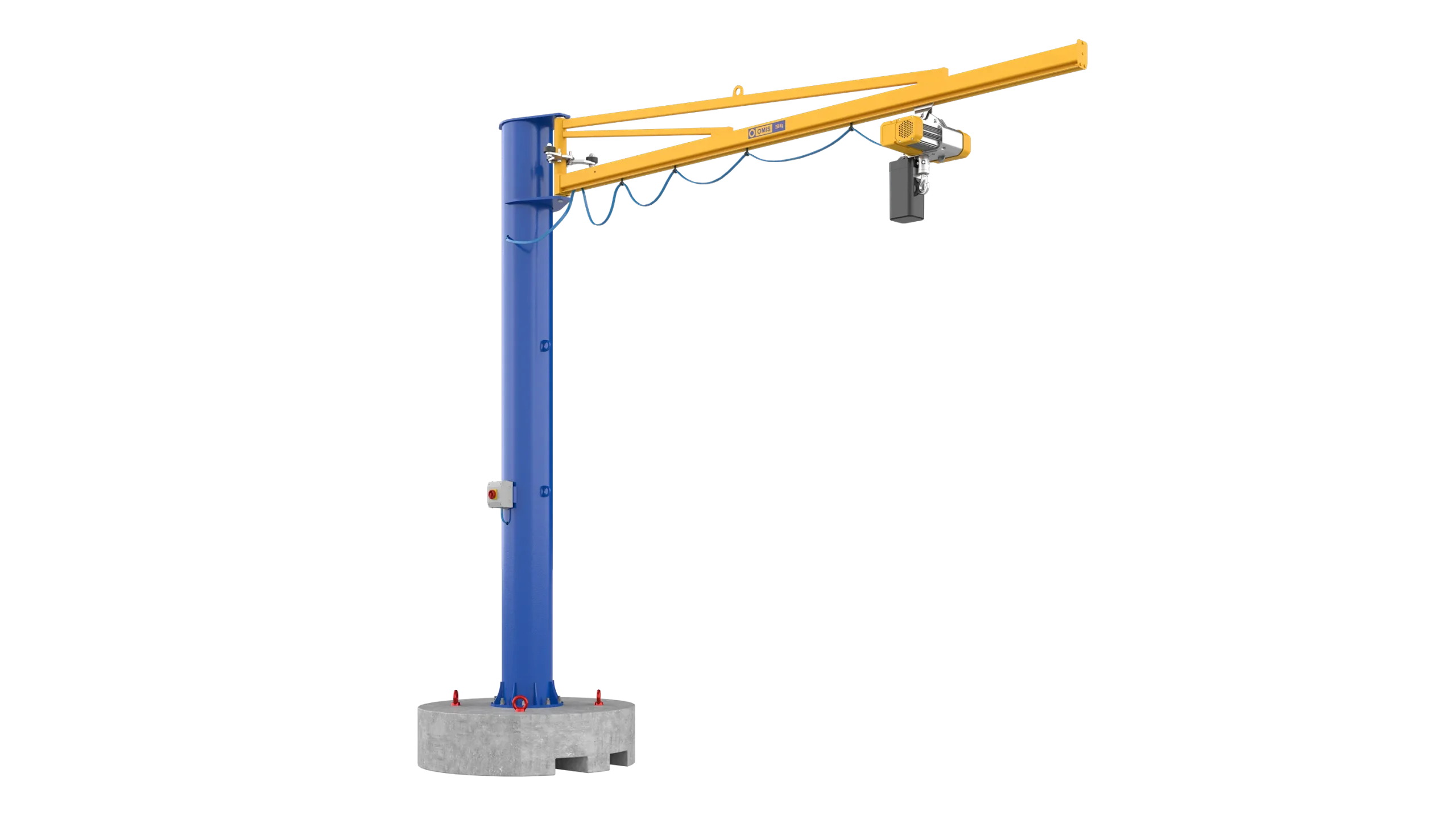

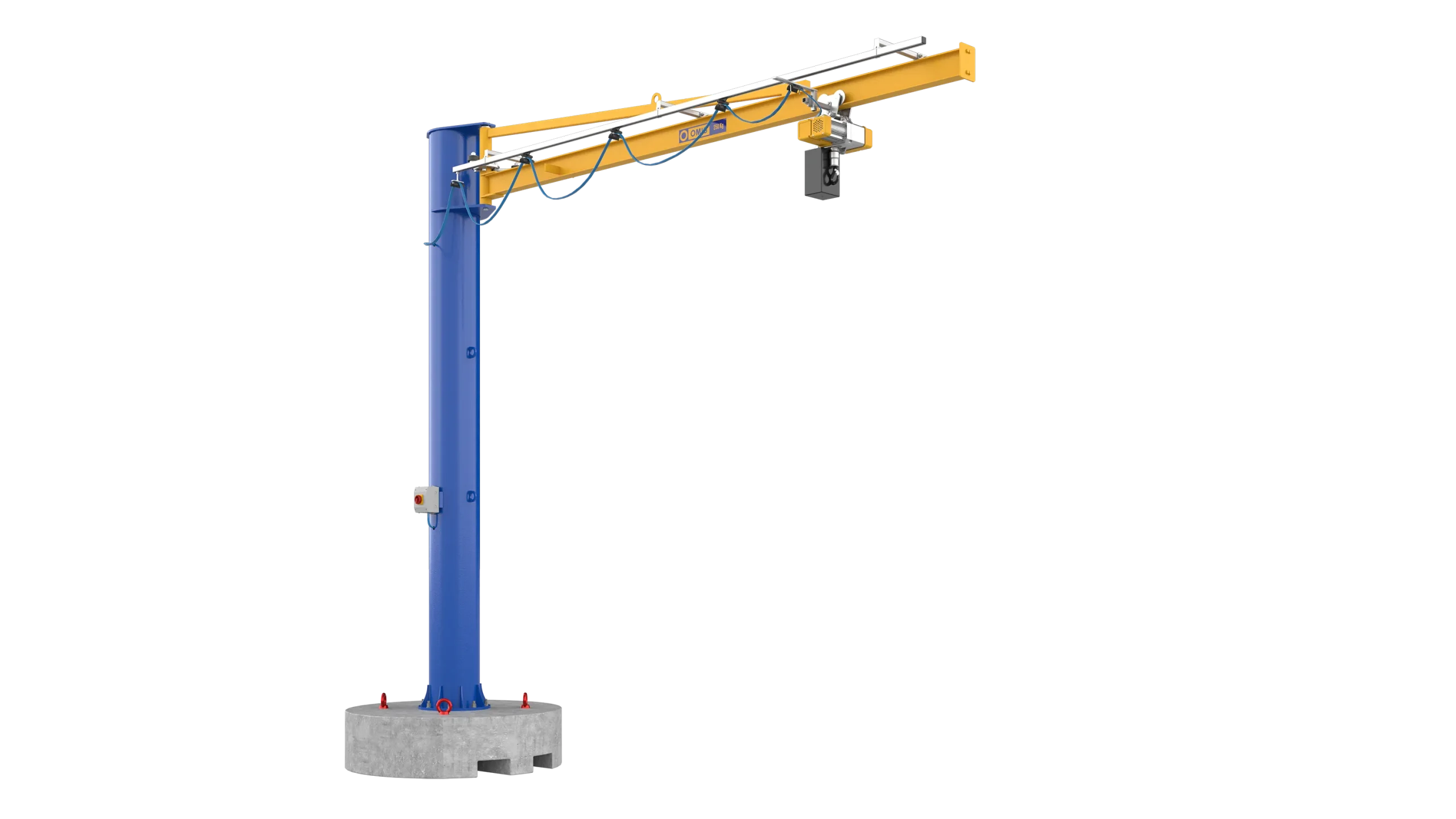

Pillar jib crane with cantilever girder boom and movable plinth with capacity up to 500 kg

The pillar jib crane with cantilever girder boom and movable plinth is ideal for handling anywhere in the work area using a forklift or overhead crane. It is a special solution that is not constrained by a permanent anchorage to the ground. A second specific advantage of this jib crane is the possibility of ensuring maximum use of the available height, with consequent increase of the available hook stroke.

All these features make it a highly versatile tool, as well as being easy to handle and highly economical, both in installation and in the day-to-day operation of the work area served The mobile jib crane, with self-supporting cantilever girder boom and without tie rods, is used for handling light loads in a variety of industrial applications, from small workshops to large assembly lines, food production plants or wine cellars.

Advantages of the pillar jib crane with cantilever girder boom and movable plinth

Capacity

125 kg - 500 kgExtension

Up to 6 m depending on capacityExtension profile

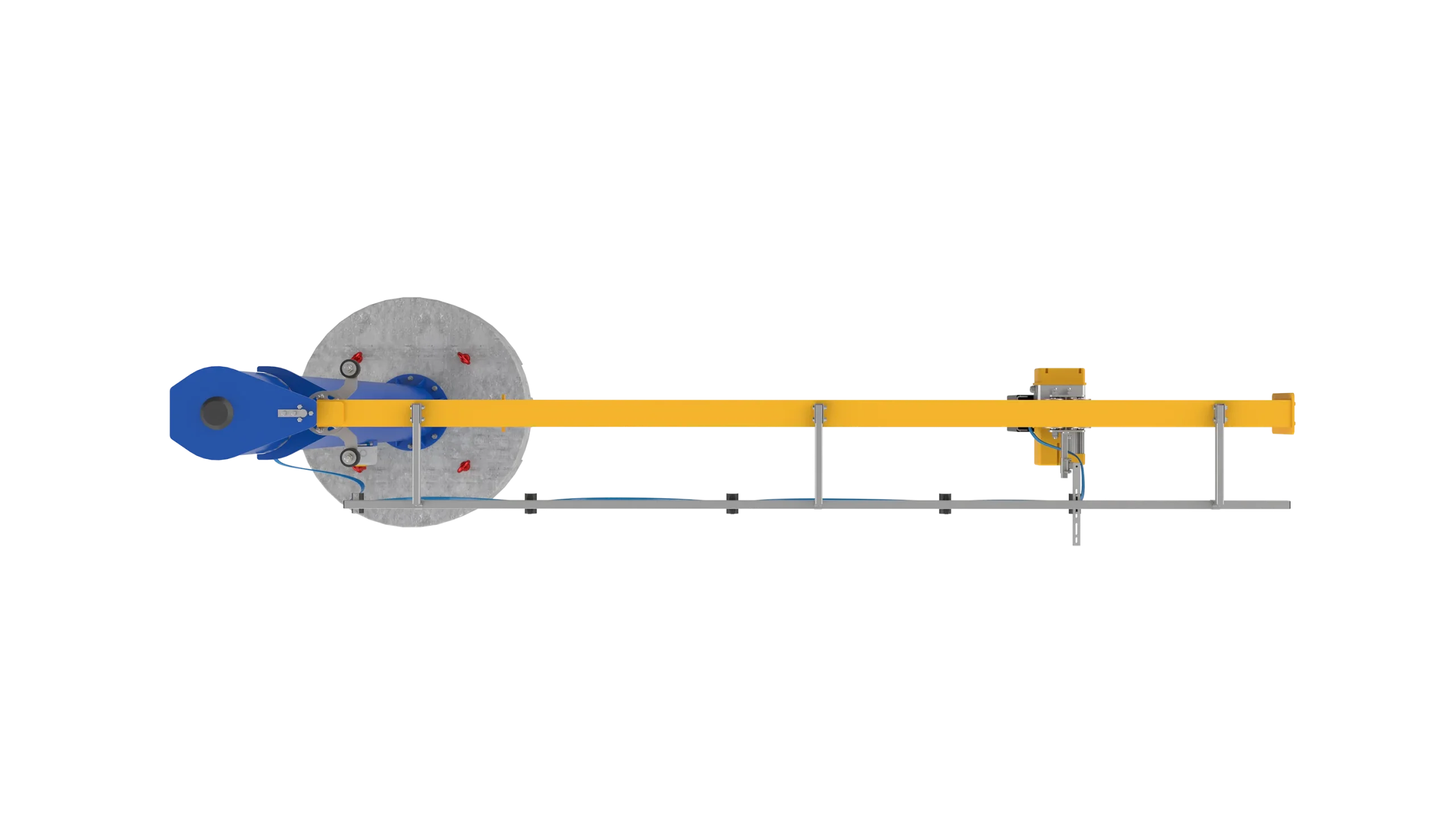

Profile with I beams without tie rodsRotation

270° with stop adjustable on site depending on architectural dimensionsPlinth

Movable round plinth in concrete or steel formwork with concrete fillingPillar

Circular-section tubular steel. At one end it has a perforated base plate for anchoring to the base using chemical anchors or anchor rods, and at the other end two plates, a head plate and an intermediate plate, for supporting the boom.Hoist

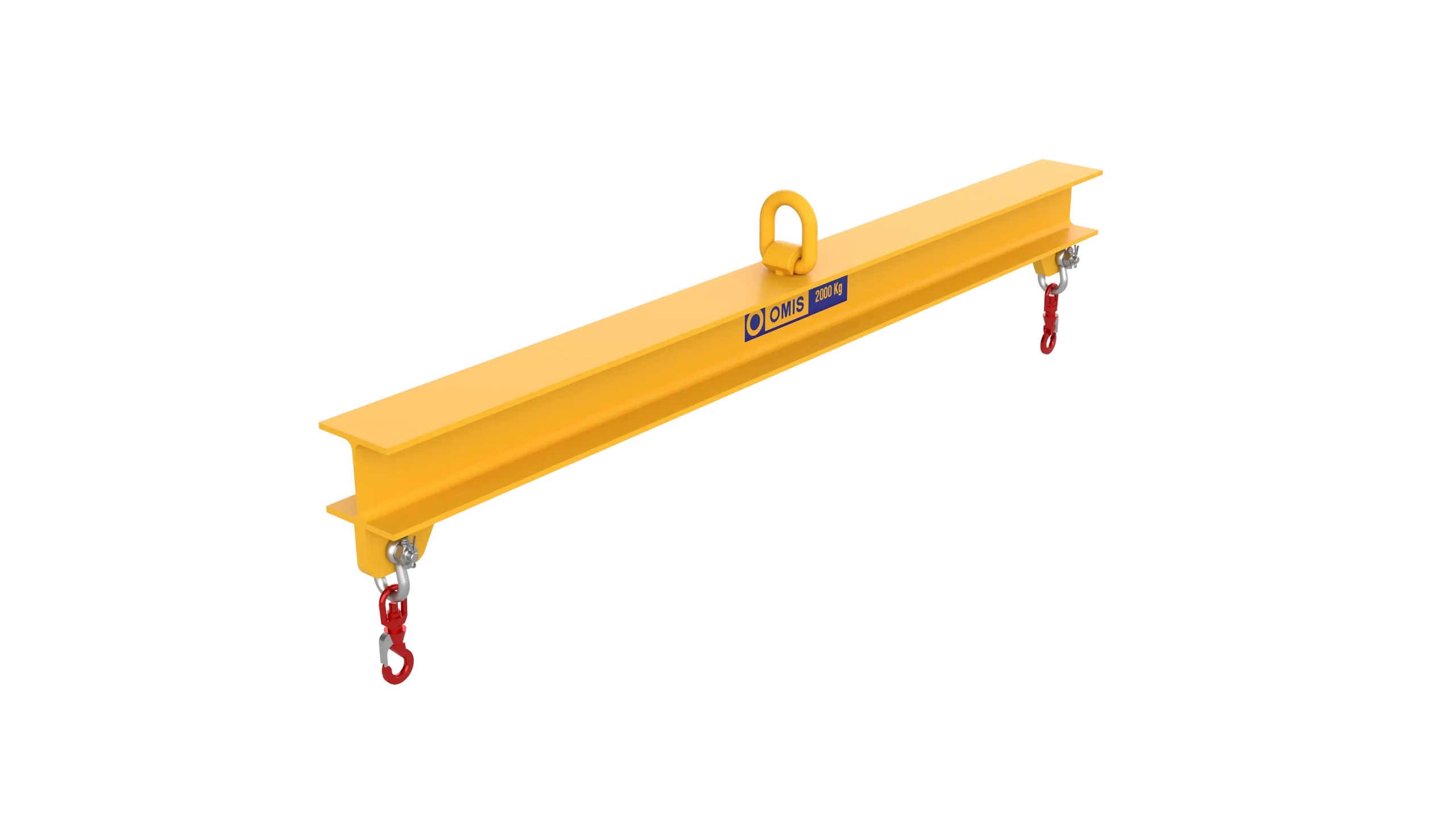

Chain or rope electric hoist for lifting the load, with one or two lifting speeds, with electric or push trolley.Braking device

This consists of a screw-adjustable clutch for the adjustment of the boom rotation effort and for ensuring its positioning stability.Custom paintwork

Emergency response and scheduled maintenance. Repairs, upgrades, modifications and checks aimed at assessing residual life.

Born to innovate.

Raised to increase values.

OMIS is a manufacturer of excellence, a safe and reliable partner, a group that seeks and practices responsibility and sustainability. Technology, dialogue, sound principles and a forward-looking outlook fuel strategies, industrial approach and environmental awareness.