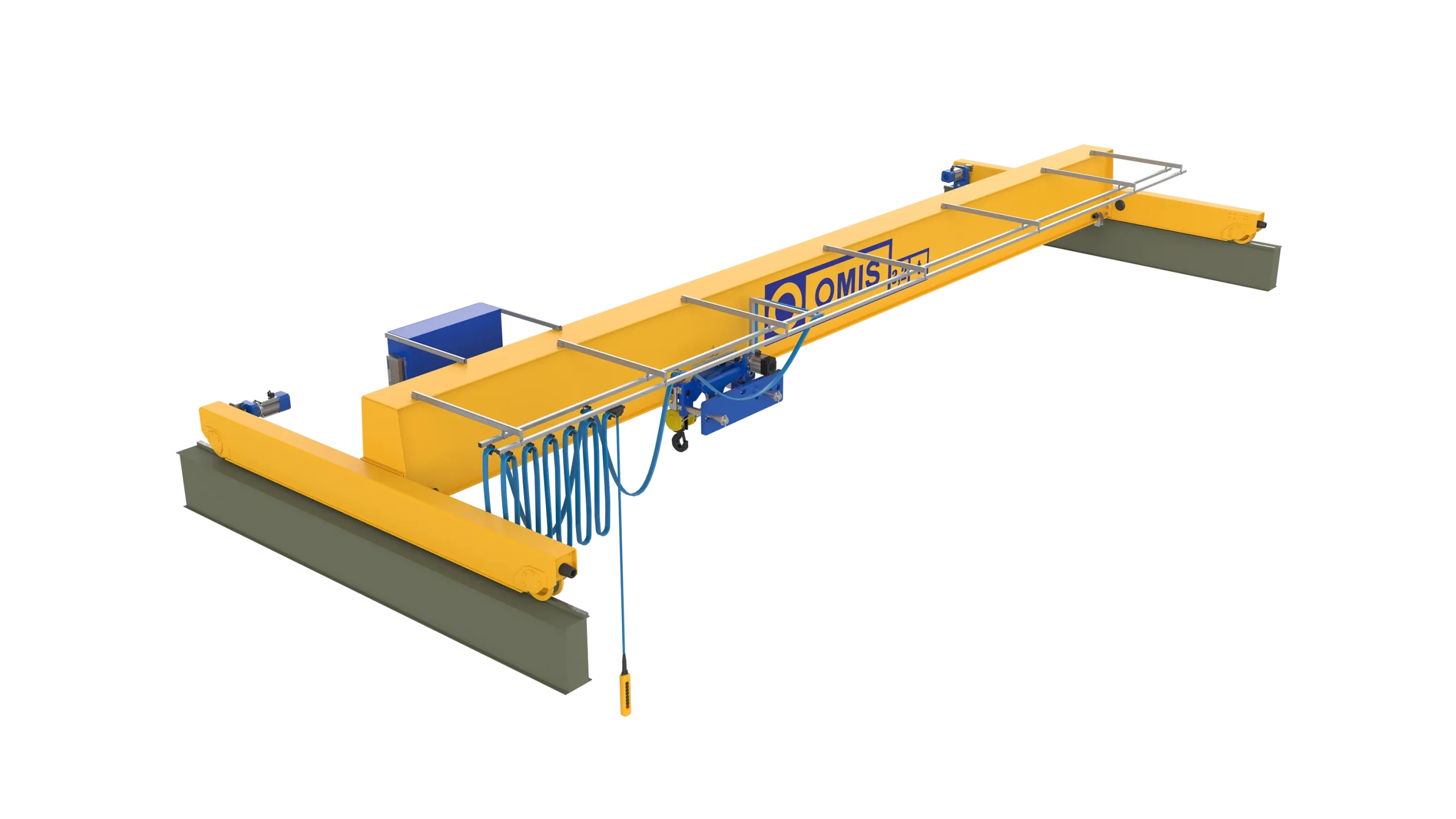

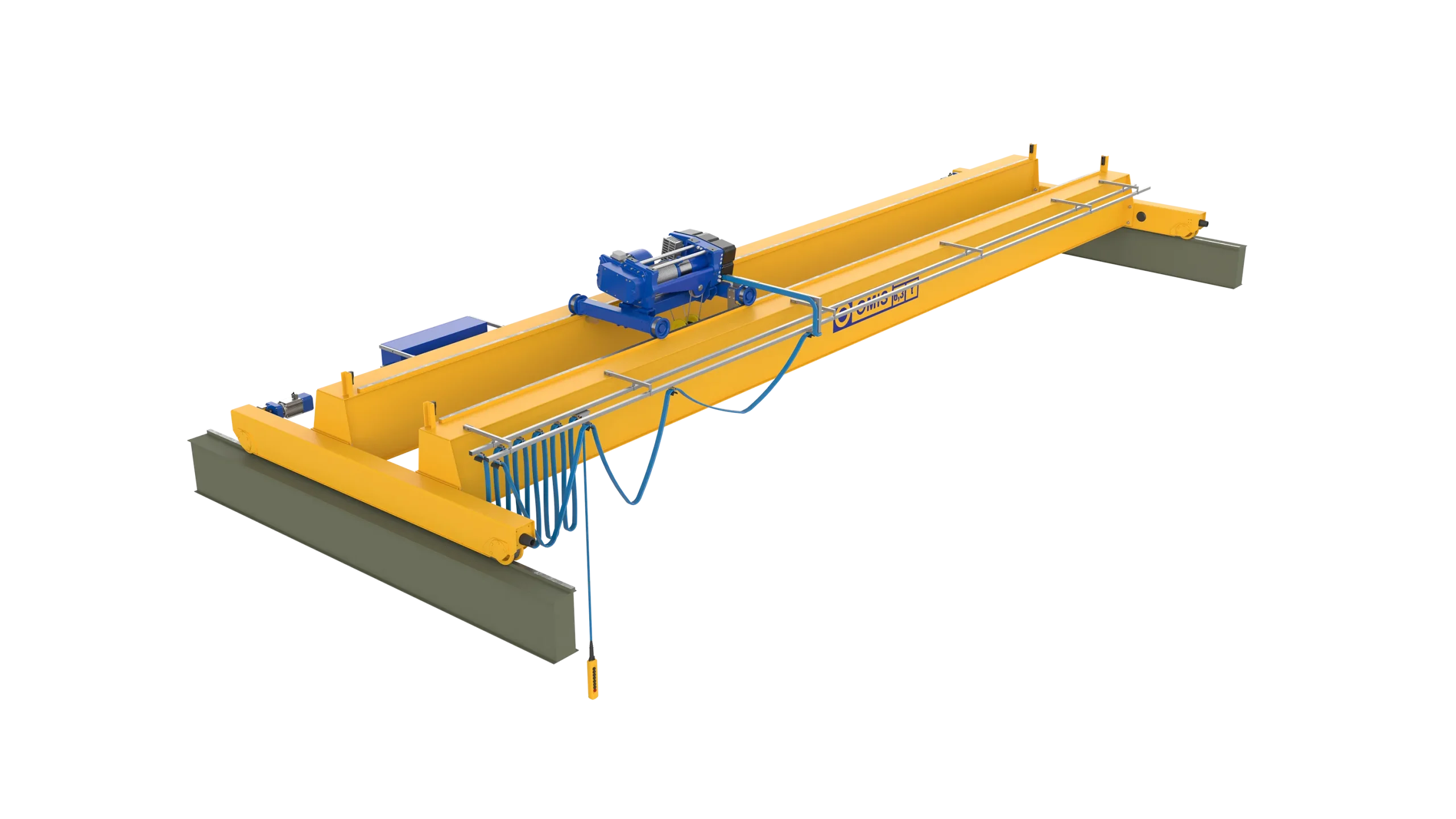

The H series electric hoists are one of the top products in the OMIS range and represent the most advanced and versatile response on the market to the industrial requirements for this type of equipment. Designed and manufactured by one of the world’s leaders in lifting solutions, they naturally integrate perfectly in complete and efficient systems with other OMIS solutions, enhancing their performance to the maximum.

With their trolleys and electrical panels, they are also able to operate and raise the total yield and quality even when applied to systems built by other manufacturers.

Designed to support loads from 1.25 to 12.5 tonnes, the H-series hoists are characterised by their robustness, reliability, versatility, ease of maintenance and excellent value for money.

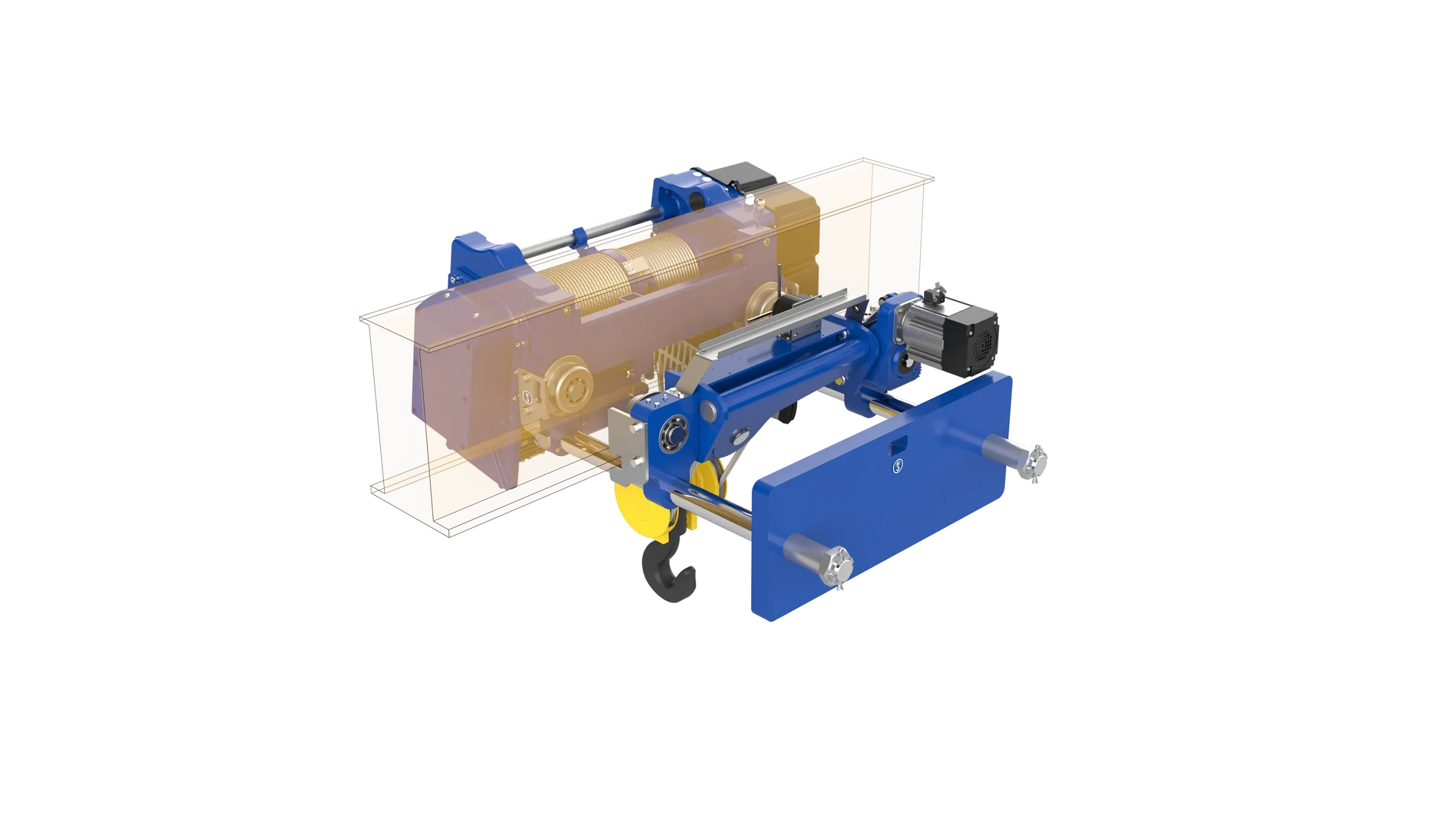

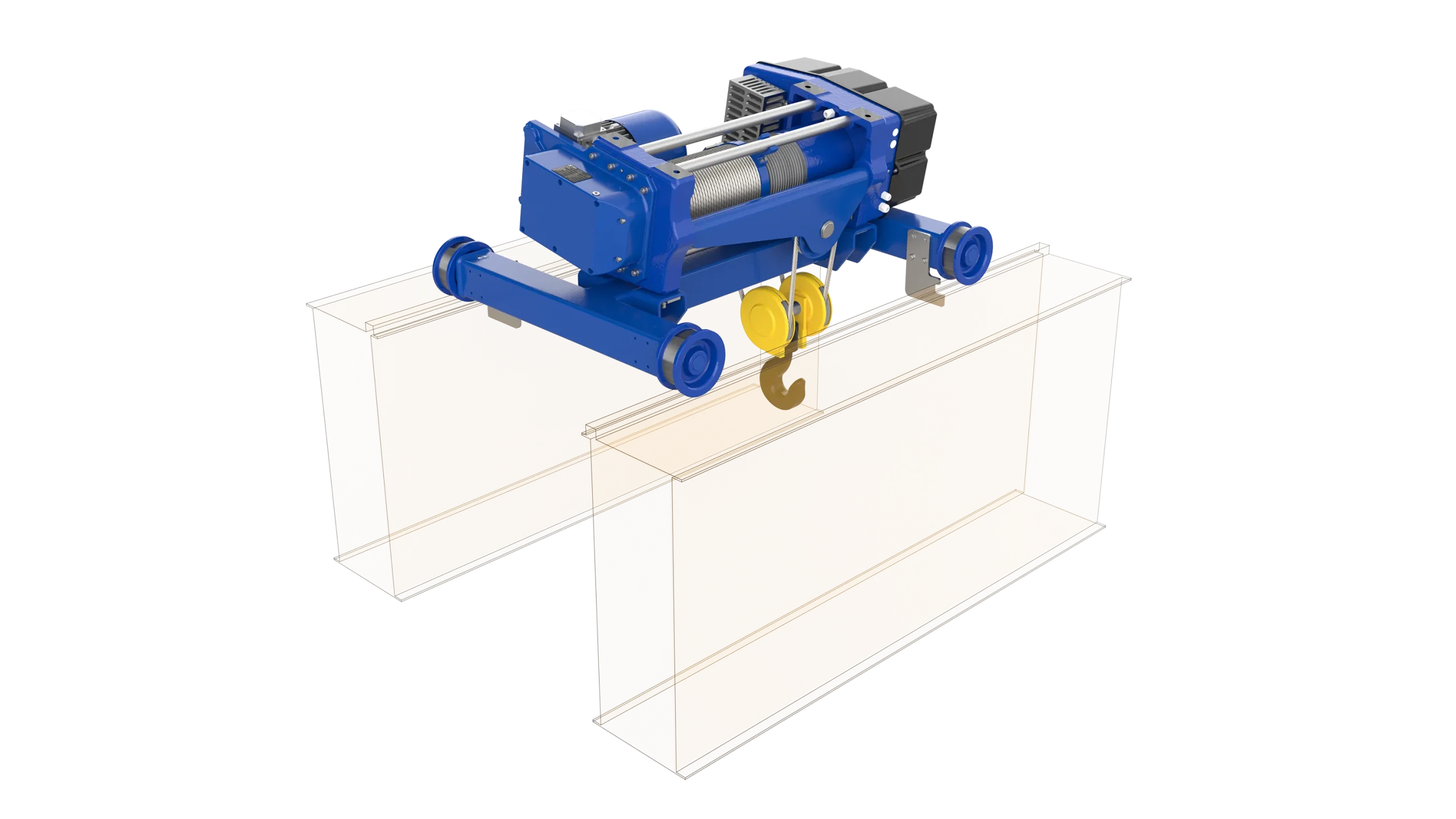

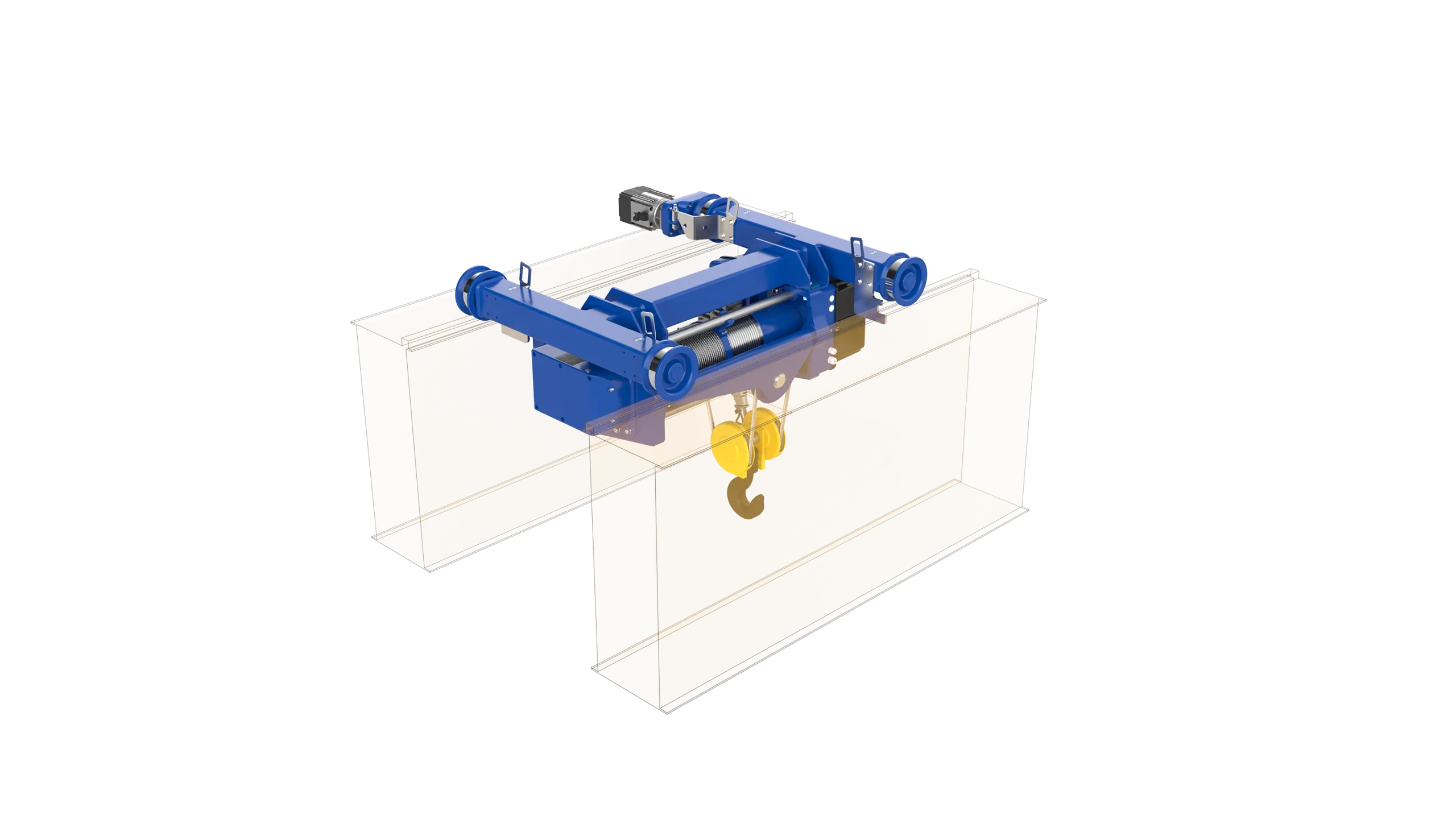

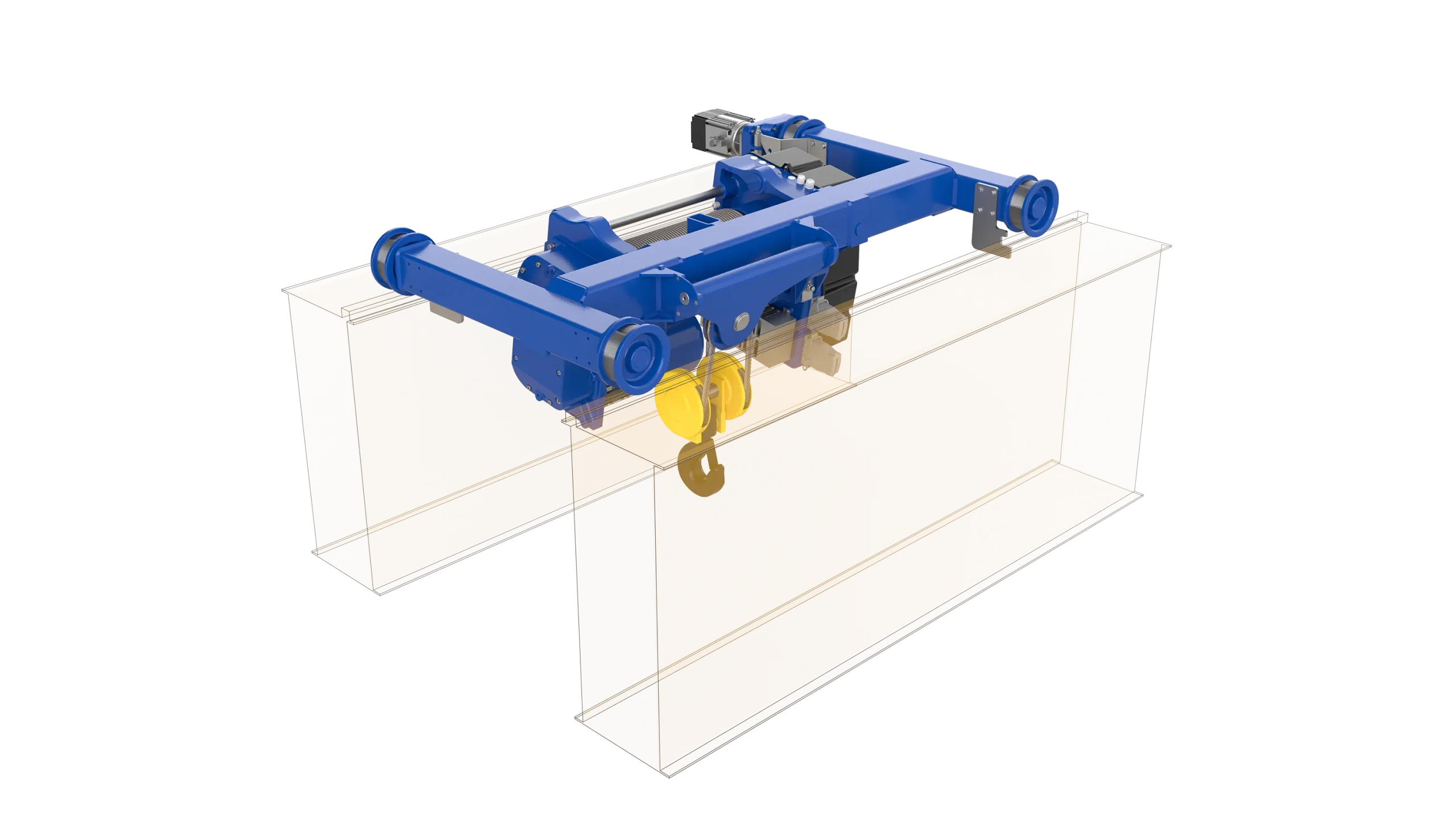

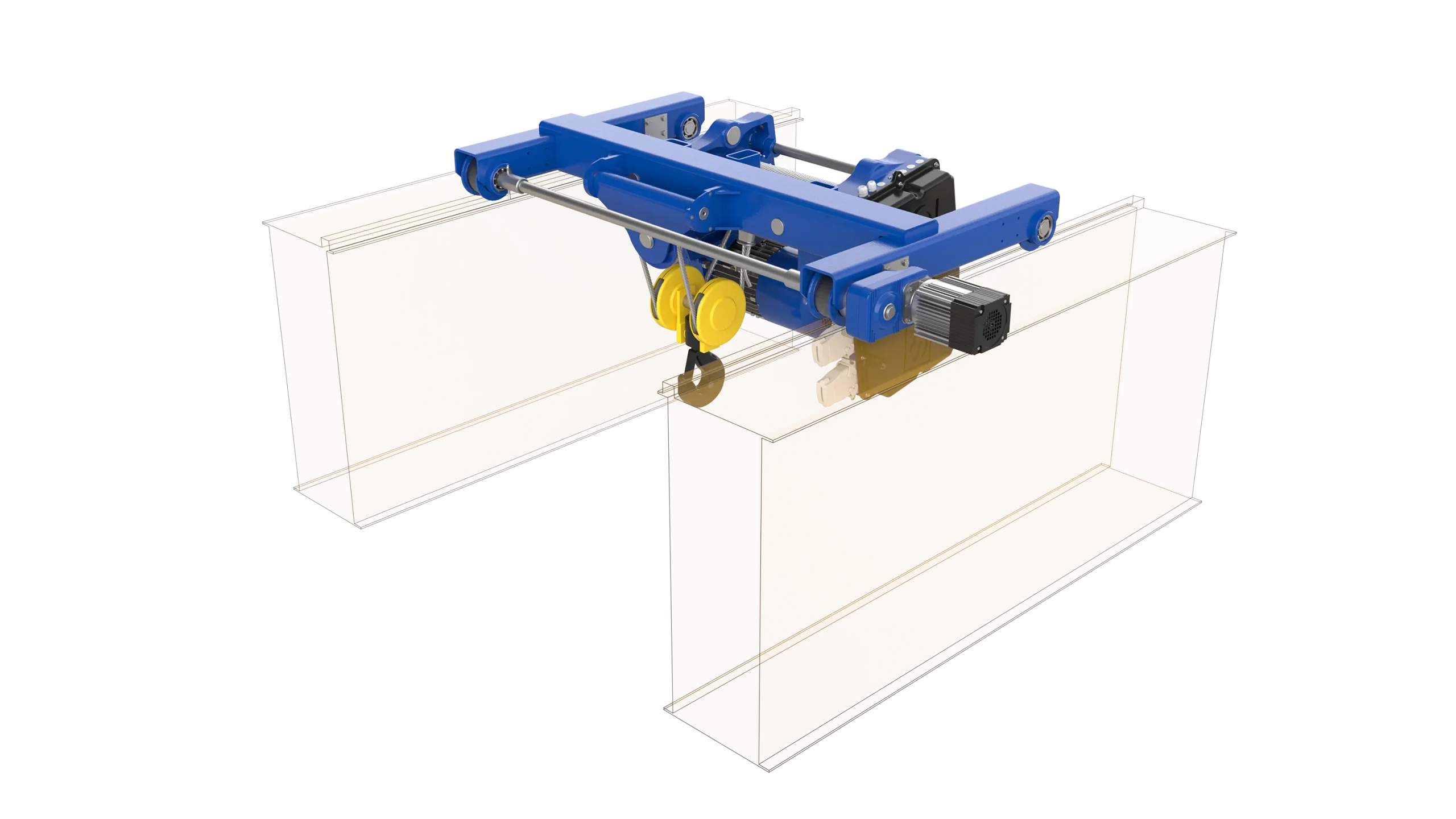

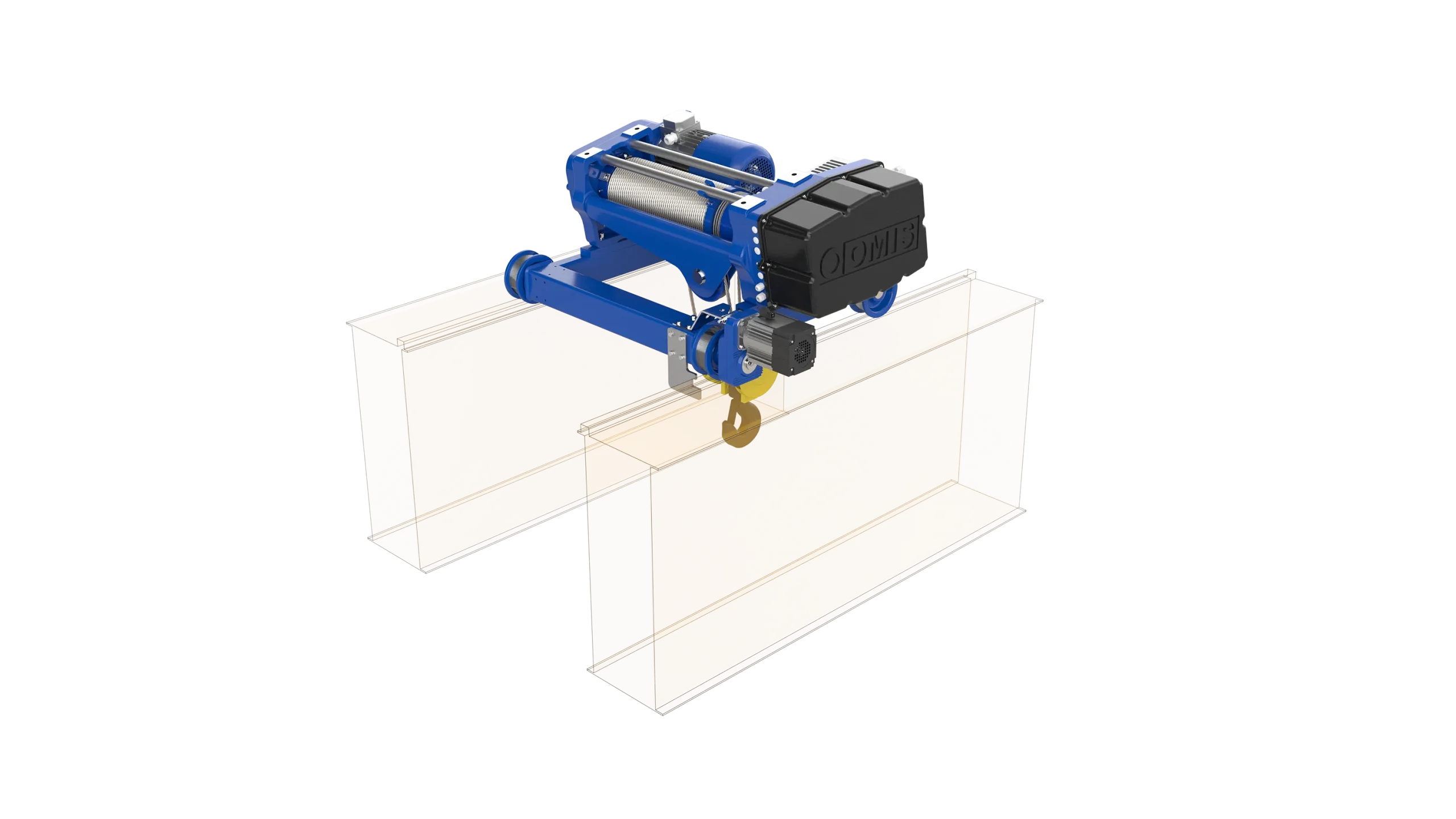

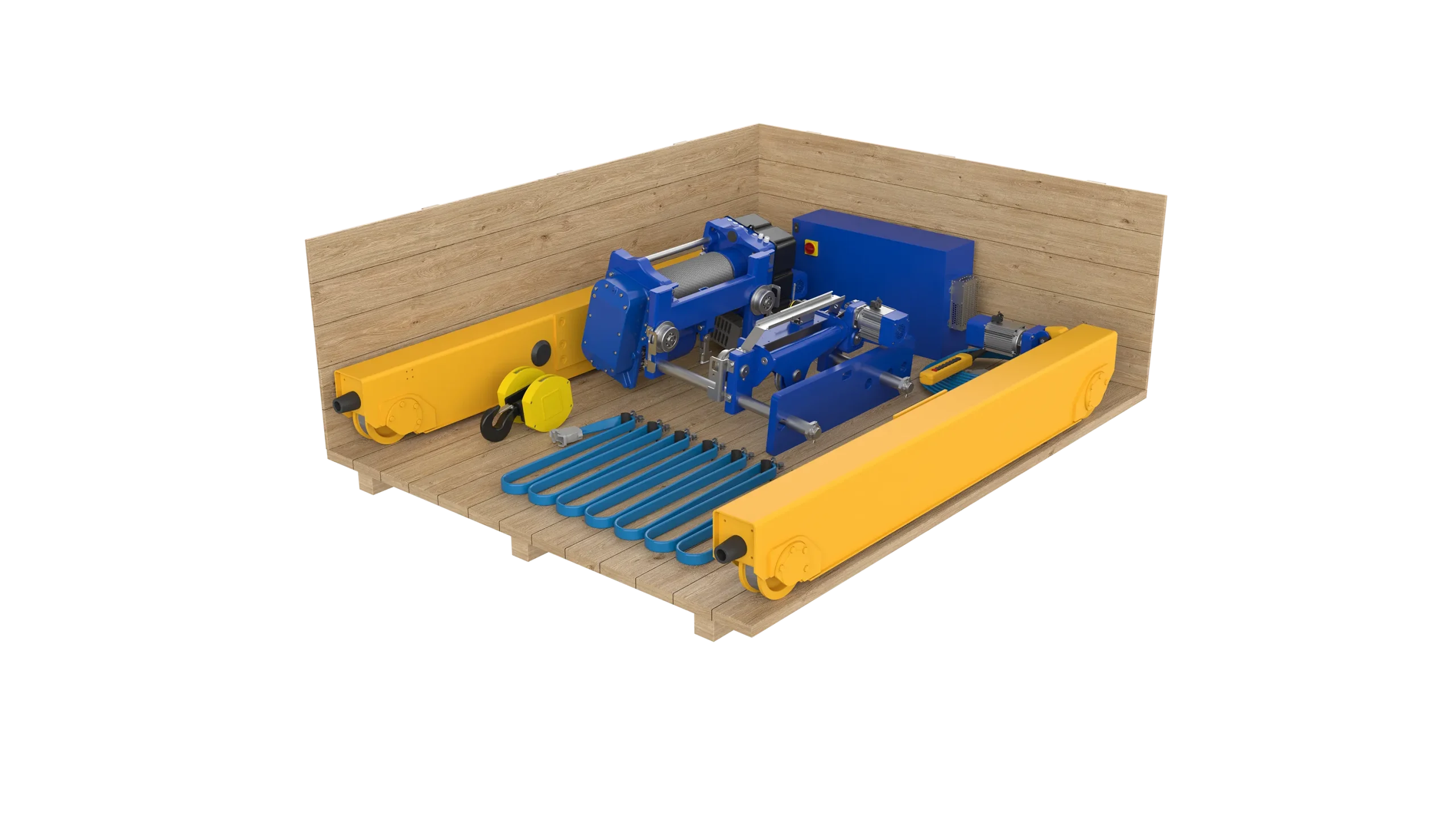

The strengths of H-Series hoists include their state-of-the-art design, small bulk, inverter-powered self-braking motors, OMIS gearboxes, fully integrated electrical panel and top-quality ropes. The many configurations of the OMIS hoists allow installation on various types of trolleys, single- and double-beam or fixed execution for maximum installation flexibility.

Each hoist is designed, tested and built entirely at the group’s facilities. Thanks to fifty years of experience and a tradition of ongoing research and innovation, OMIS can guarantee the highest standards of safety, component quality, equipment, technology and environmental compatibility for each configuration.