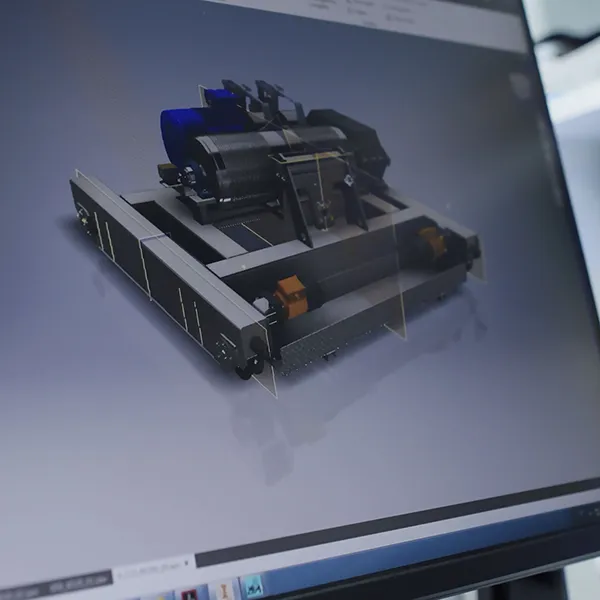

Select a product and identify version, style and optional extras to configure the OMIS system that best suits your needs.

Collaborative workstation systems. Reliable, innovative and for every application

Lifting and handling systems for workstations or light lifting equipment are essential to ensure efficiency, safety and productivity in various industrial and manufacturing sectors. Among them, jib cranes, portable gantry cranes, monorail cranes and suspended installations provide versatile solutions that can be adapted to different operational requirements.

Stemming from an in-depth knowledge of a wide variety of applications, the light lifting systems offer a complete range of solutions for handling loads of up to 10,000 kg. Production using industrialised processes enables the manufacture of reliable, technically innovative cranes with an excellent price/performance ratio. The quality of the components used and the excellent finish of the structural work make it possible to offer a product of the highest standard, as well as to always meet the demands of standardised and special installations. Real collaborative process machines when used to integrate production centres, machine tools or workbenches.

Jib cranes are characterised by a rotating jib mounted on a column or fixed to a wall, and allow the lifting and handling of loads within a circular area. This type of crane is ideal for precision operations and lifting loads of moderate weight, thanks to its ease of installation and flexibility of use. Jib cranes are widely used in machine shops, warehouses and assembly lines.

Portable gantry cranes, on the other hand, consist of a portal-like structure under which the trolley and lifting hook slide. These cranes are particularly suitable for handling heavy and bulky loads, as they can cover large working areas. Thanks to their robust construction and the possibility of being mobile or stationary, portable gantry cranes are used in construction sites, assembly lines, large warehouses and logistics sectors.

Monorail cranes are an efficient solution for the lifting and linear handling of loads. Consisting of a single rail on which the trolley with the hook slides, these cranes are particularly suitable for predefined routes within production facilities. They offer high precision and speed of movement, making them ideal for applications that require continuity of operation following the production circuit.

Finally, suspended systems include a wide range of lifting systems that use suspended rails to move loads within a work area. These systems are extremely versatile and can be configured according to the specific requirements of the production process. They offer excellent coverage of work areas and allow loads to be moved with precision and safety.

OMIS Service

Emergency response and scheduled maintenance. Repairs, upgrades, modifications and checks aimed at assessing residual life.

Born to innovate.

Raised to increase values.

OMIS is a manufacturer of excellence, a safe and reliable partner, a group that seeks and practices responsibility and sustainability. Technology, dialogue, sound principles and a forward-looking outlook fuel strategies, industrial approach and environmental awareness.