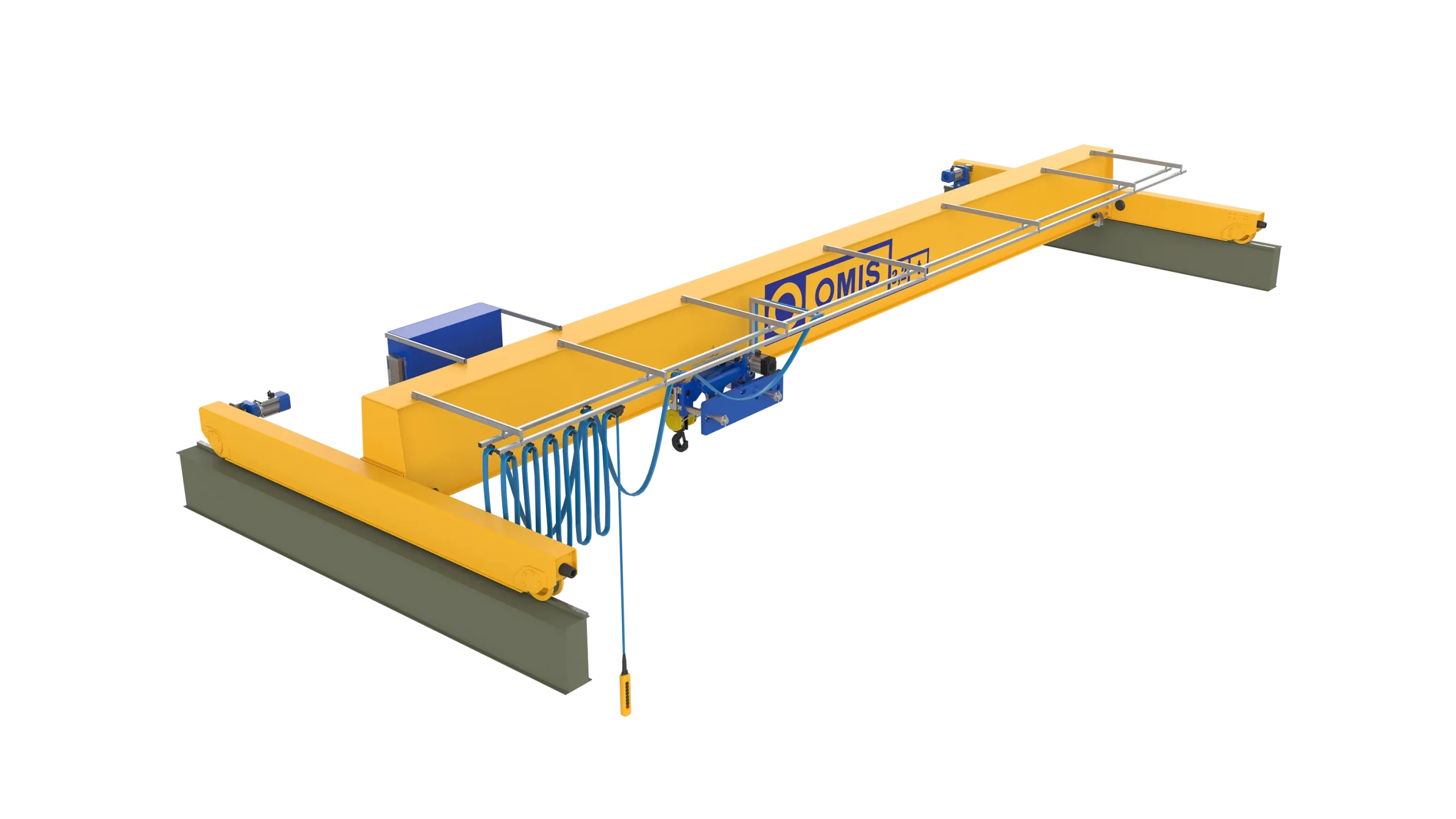

The paint colour can be customised to meet specific needs, design or branding requirements.

150t

32m

A8/M8

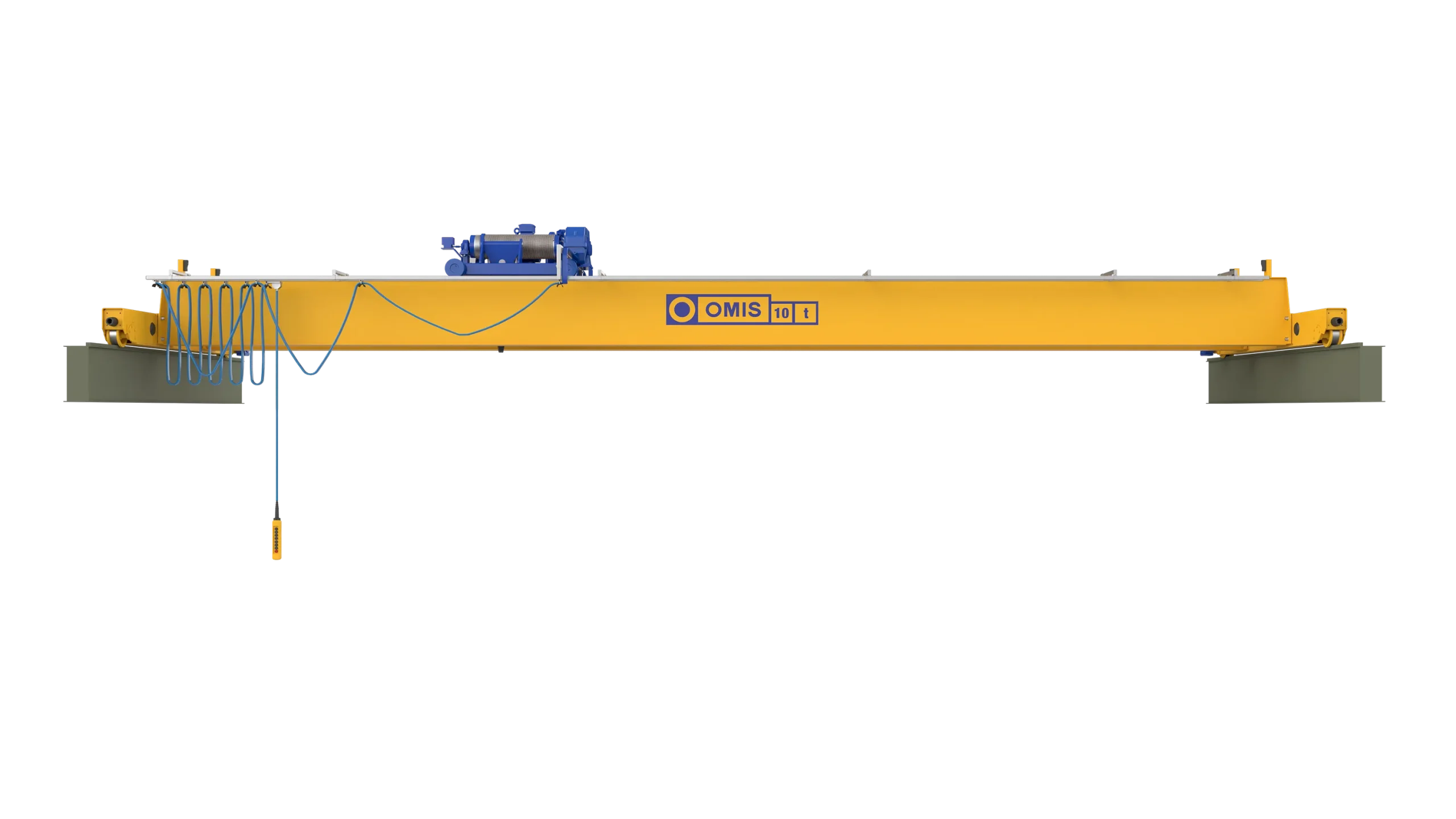

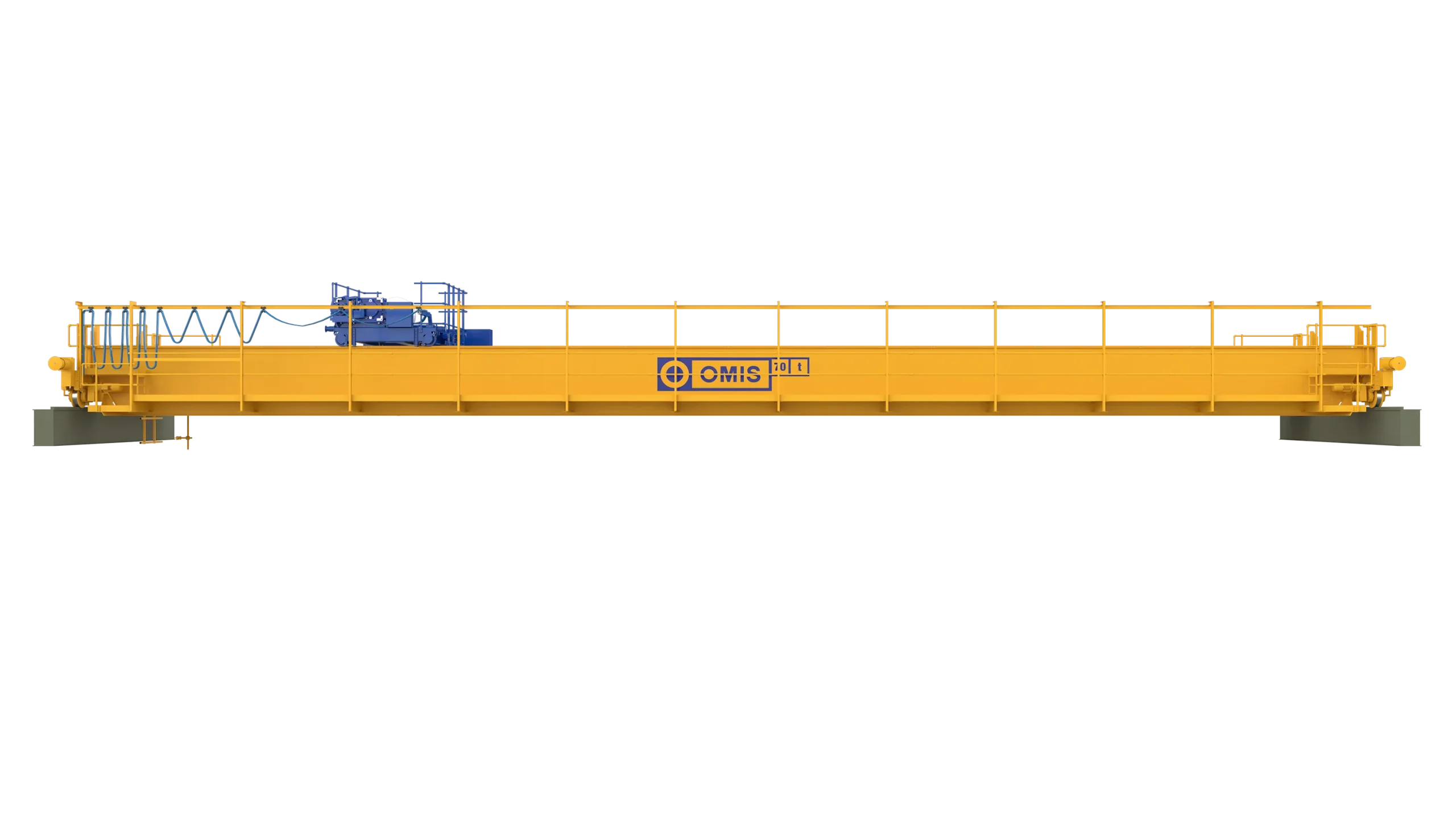

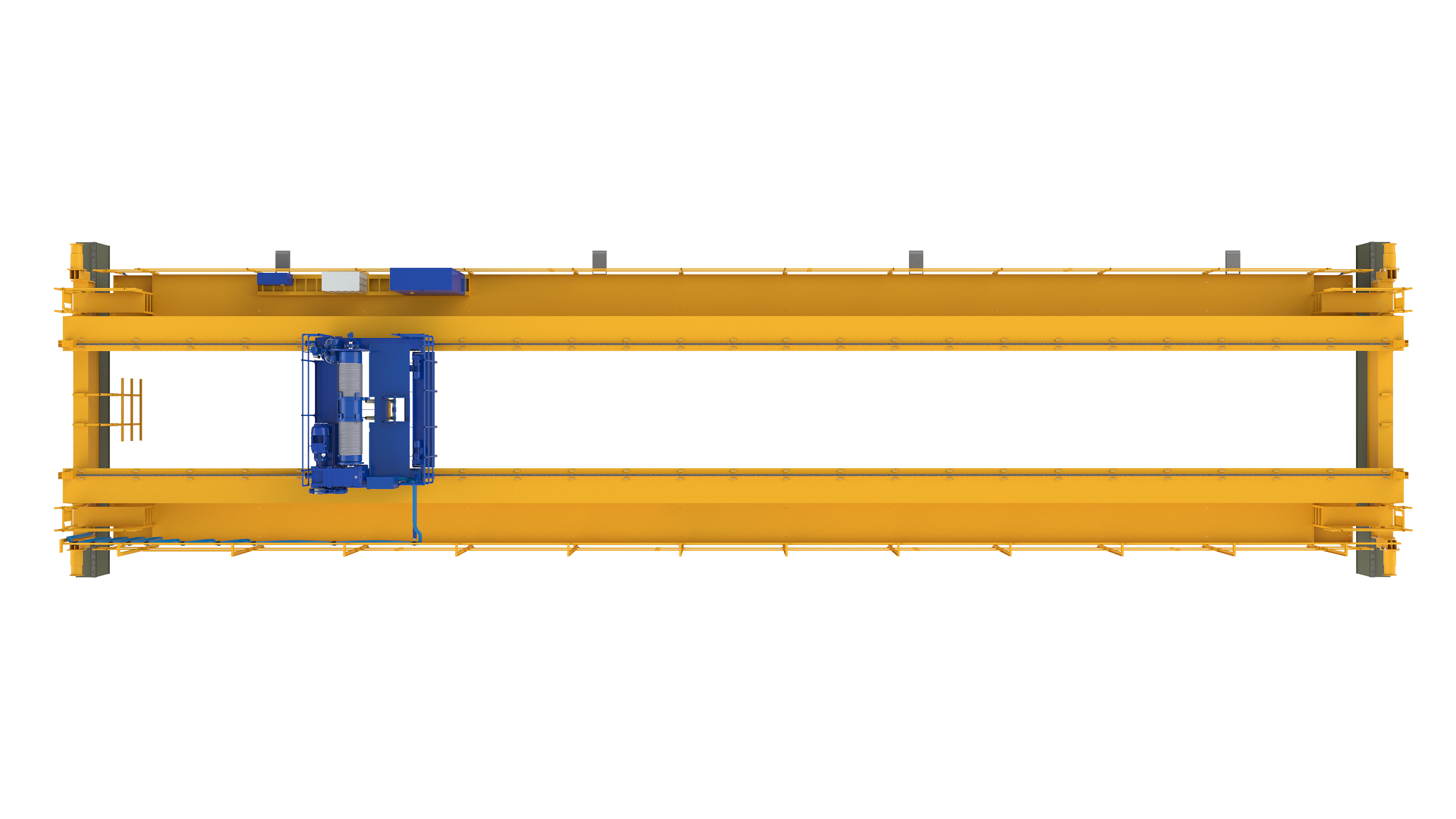

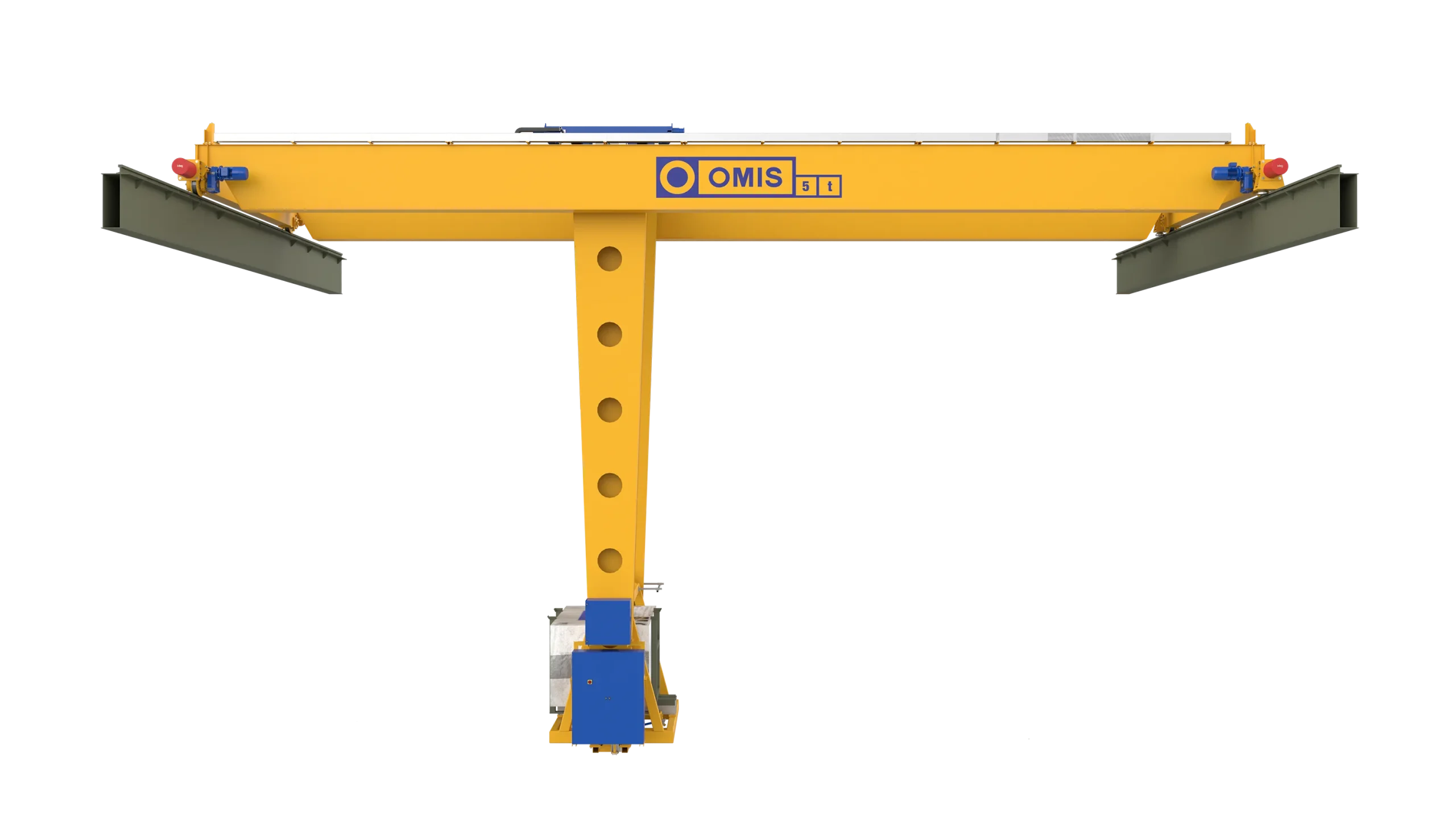

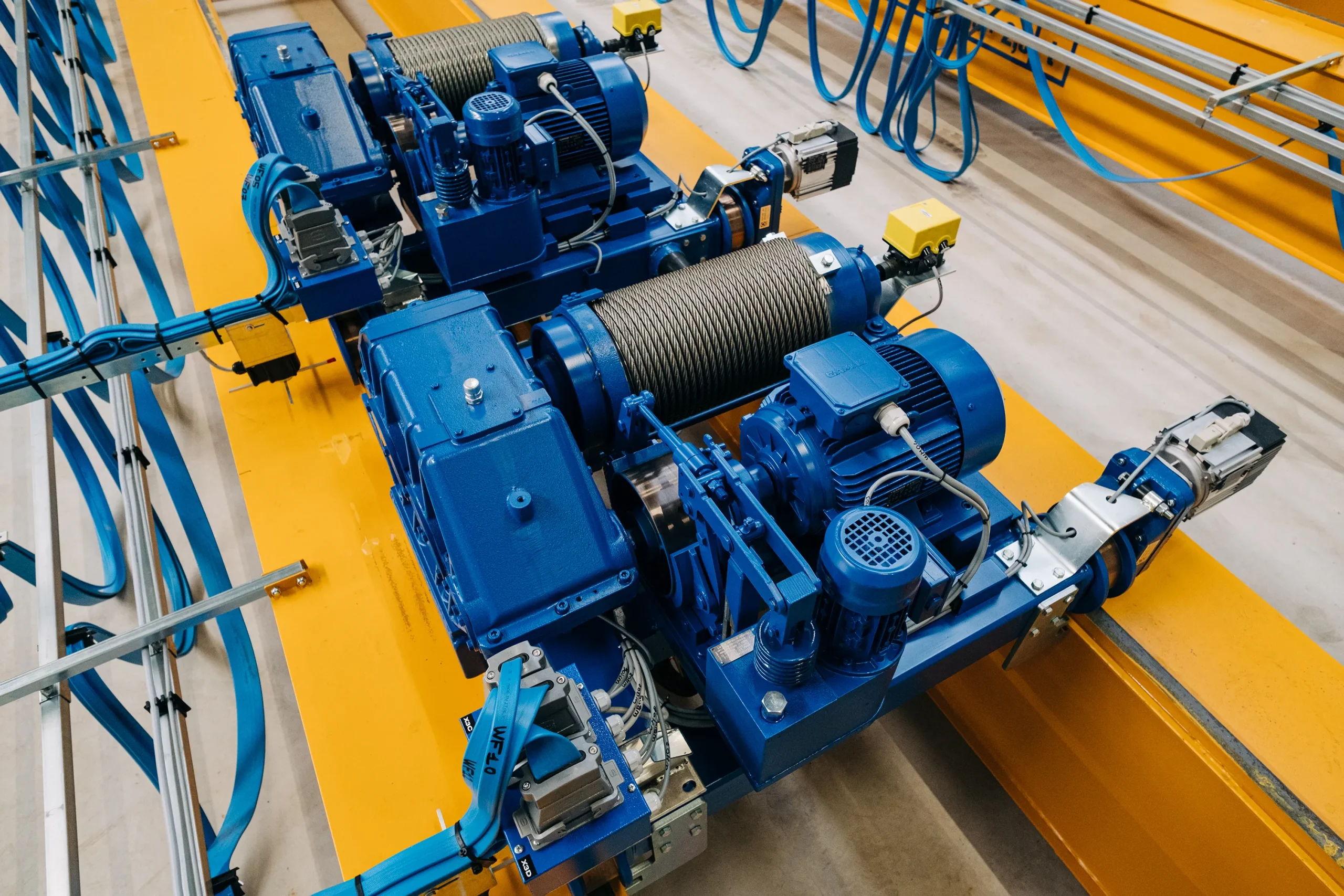

Double-girder overhead crane with capacity up to 150 t

The OMIS double-girder overhead crane is the ideal tool to meet all capacity, span and speed requirements, in every environment and sector, including the most demanding in terms of structure and performance.

The crane comes with a wide range of accessories and variable configurations, enabling optimal lifting heights, limiting hook loss, and leading to a high degree of automation.

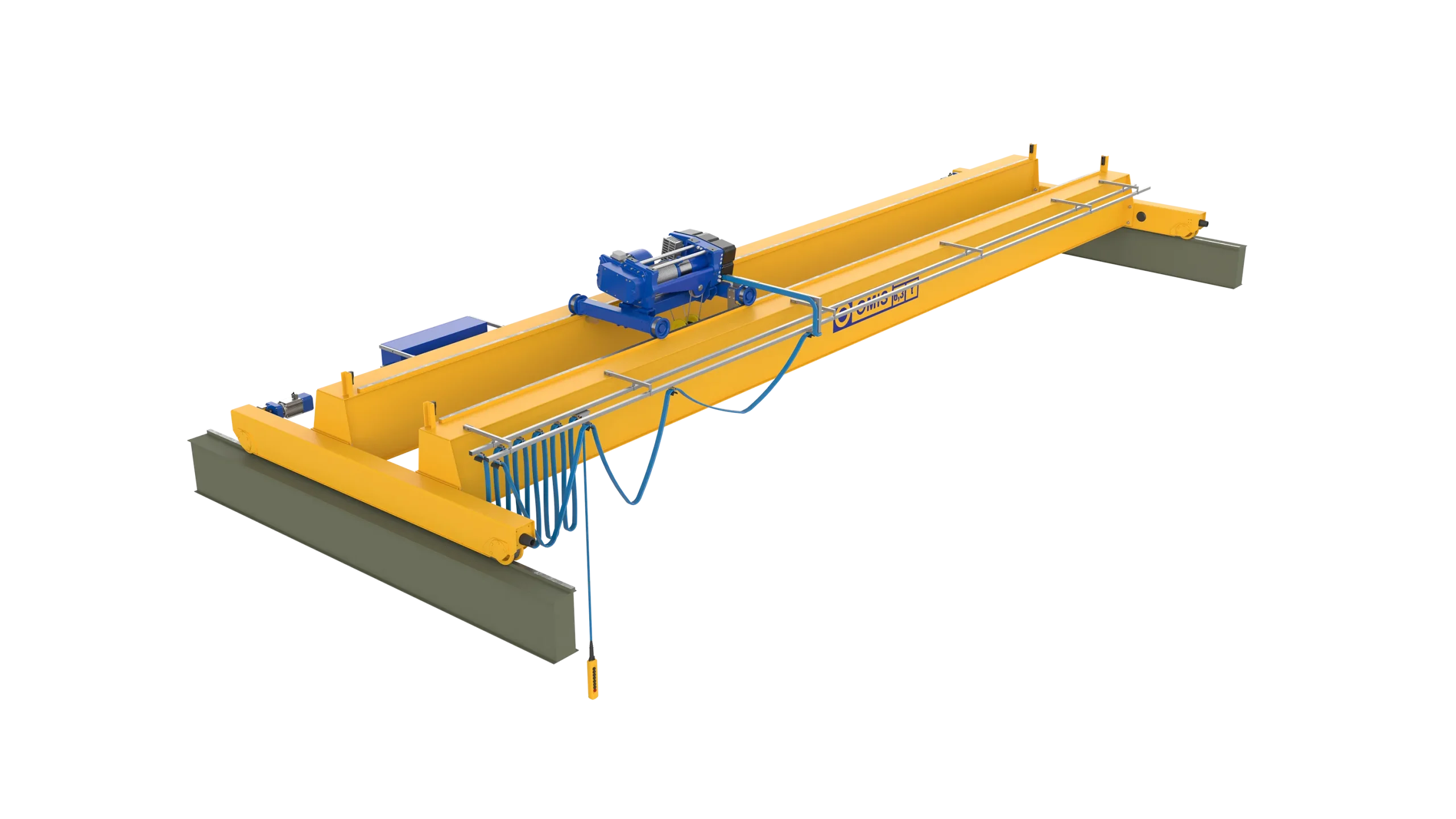

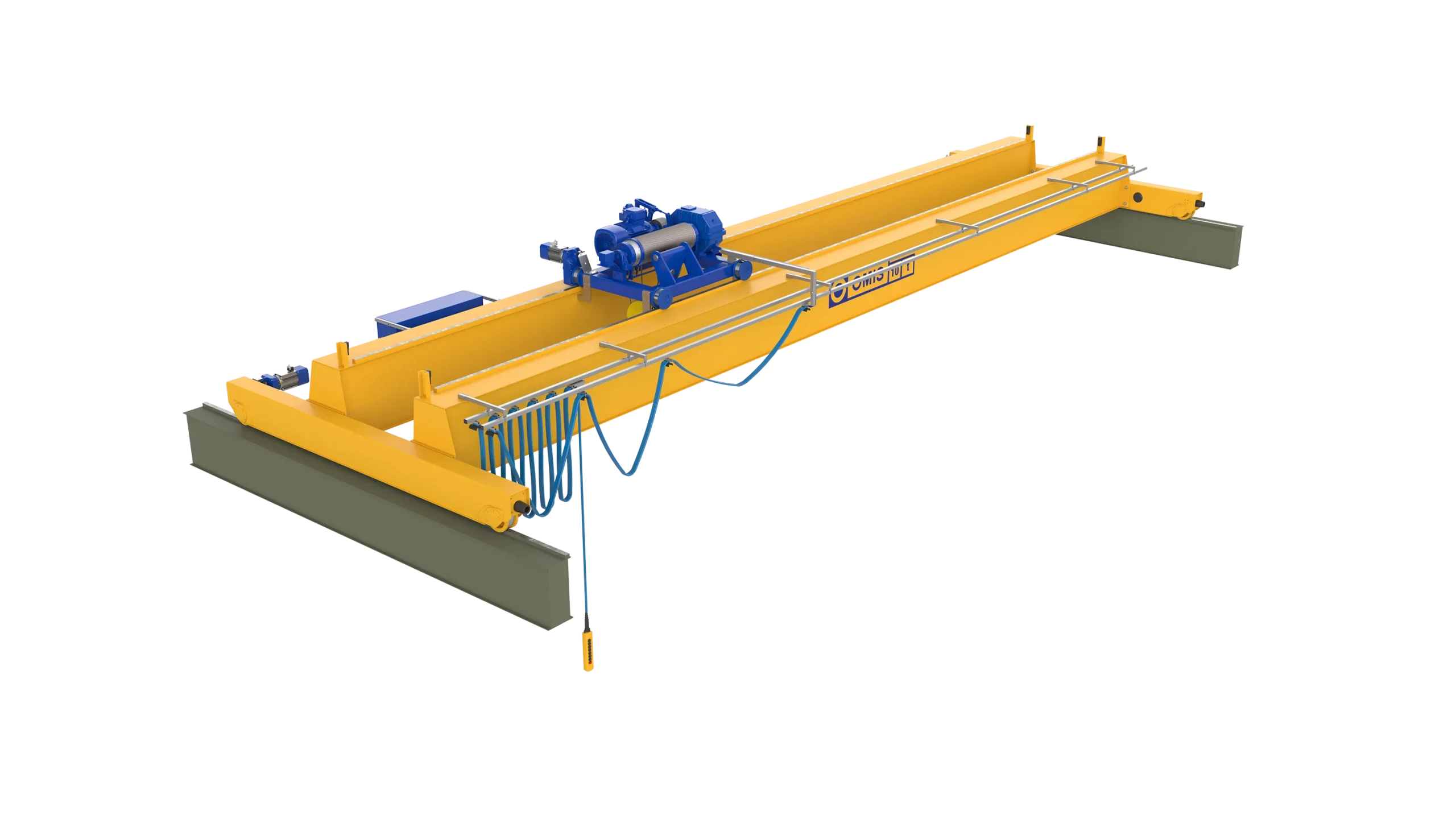

The standard double-girder overhead cranes have a load capacity of up to 150 tons and a span of up to 32 m. For a load capacity of up to 12.5 tons, OMIS double-girder overhead cranes can be fitted with a hoist or open barrel hoist. The cranes use inverters, though double-speed motors are also made available on request. OMIS is the first company of its kind in Italy to make extensive use of inverter technology, as it ensures smooth movement and minimal maintenance of all the mechanical and electromechanical parts. For special requirements, the girders can be supplied with bolted joints, which makes it possible to transport them by land and sea in containers. Standard double-girder overhead cranes are A5/M5 classified according to the FEM standards, but are also available with A6/M6 classification, or higher on request.

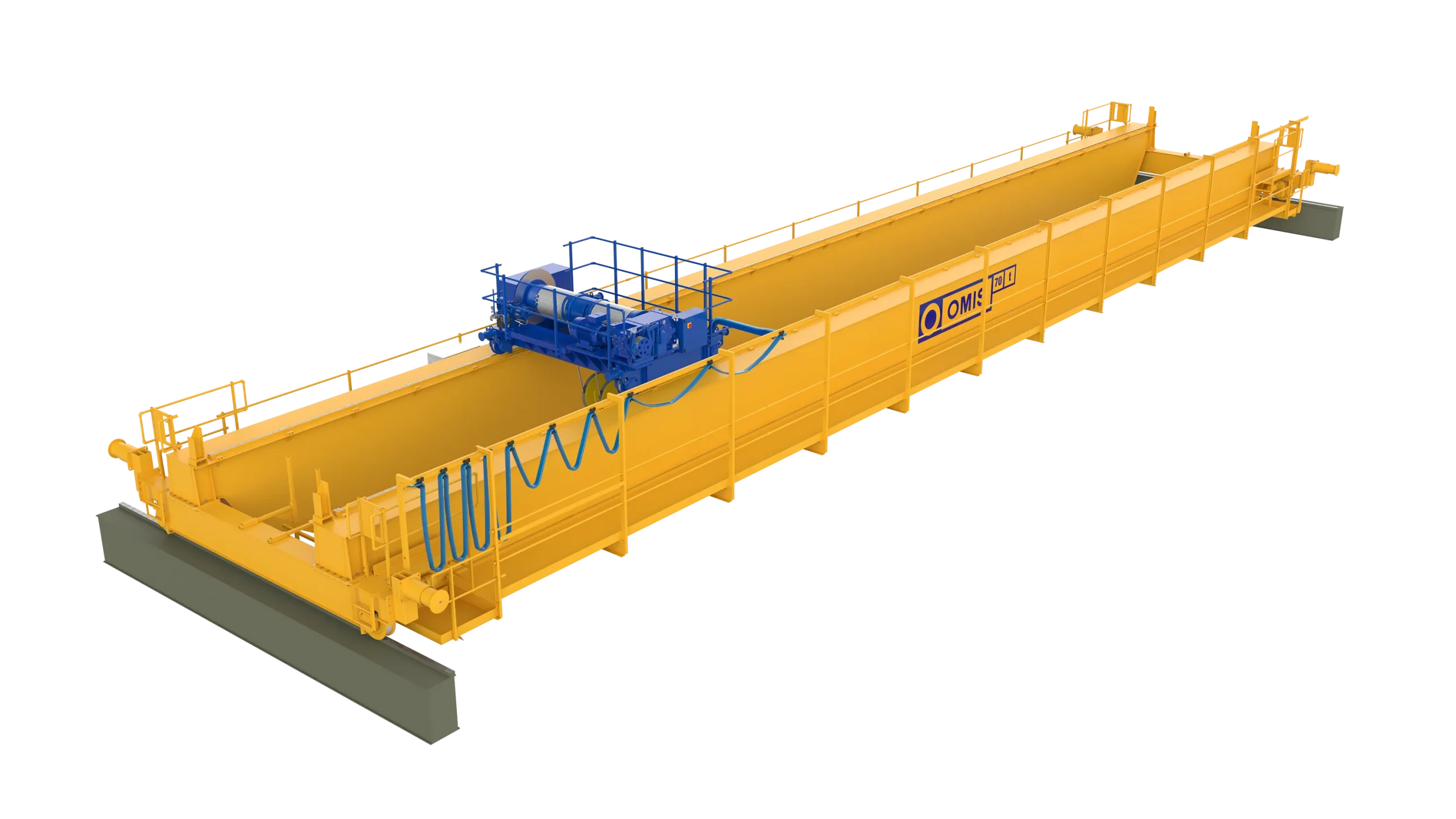

In larger cranes, used in industries such as steel mills, generator production, power plants, forges, mould making, redundant components are frequently integrated to prevent unplanned downtime. At the same time, appropriate maintenance programmes are agreed with the customer to ensure optimum performance.

Advantages of the double-girder overhead crane

Custom paintwork

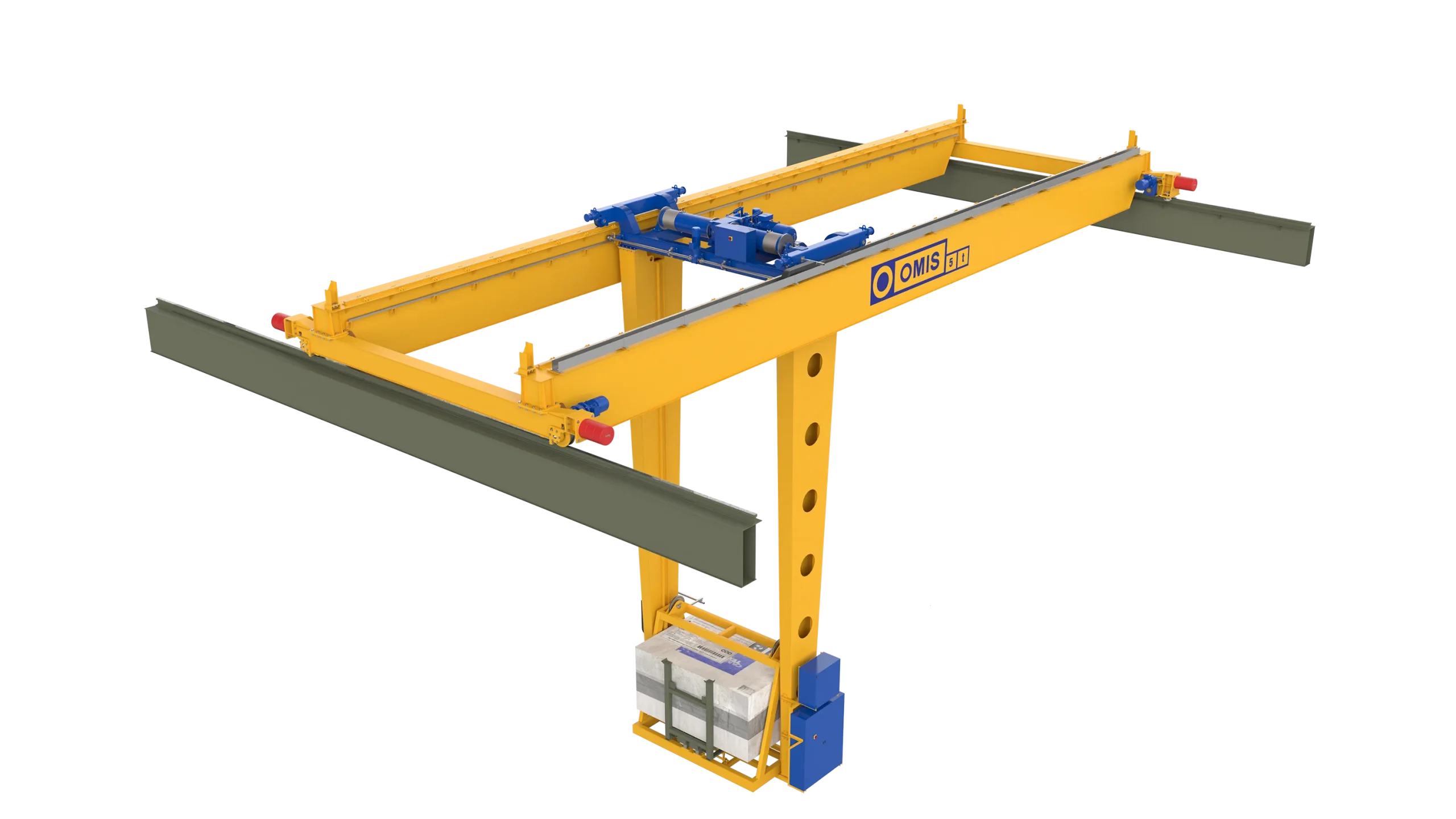

Lowered trolleys for maximum flexibility in confined spaces

Lowered trolleys allow the use of double-girder bridge cranes even in environments with limited space above the runway. Opting for a lowered trolley can offer a considerable advantage, especially when transporting bulky machinery or large containers.

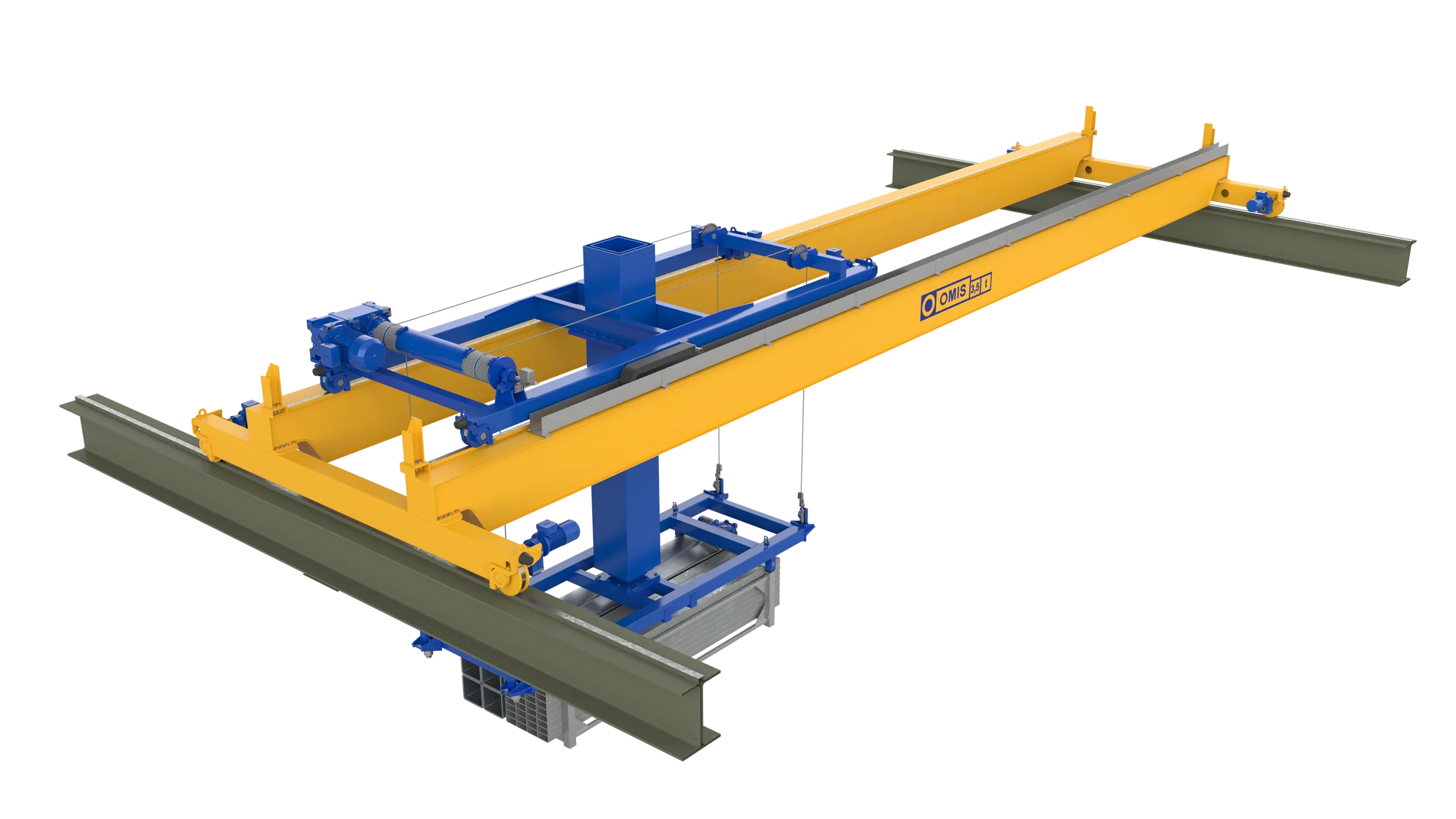

Synchronisation for handling long loads

When transporting long and bulky goods, the use of two adjacent cranes with master-slave synchronisation ensures risk-free parallel movement of the load. This approach not only increases safety, but also improves efficiency when lifting very large loads.

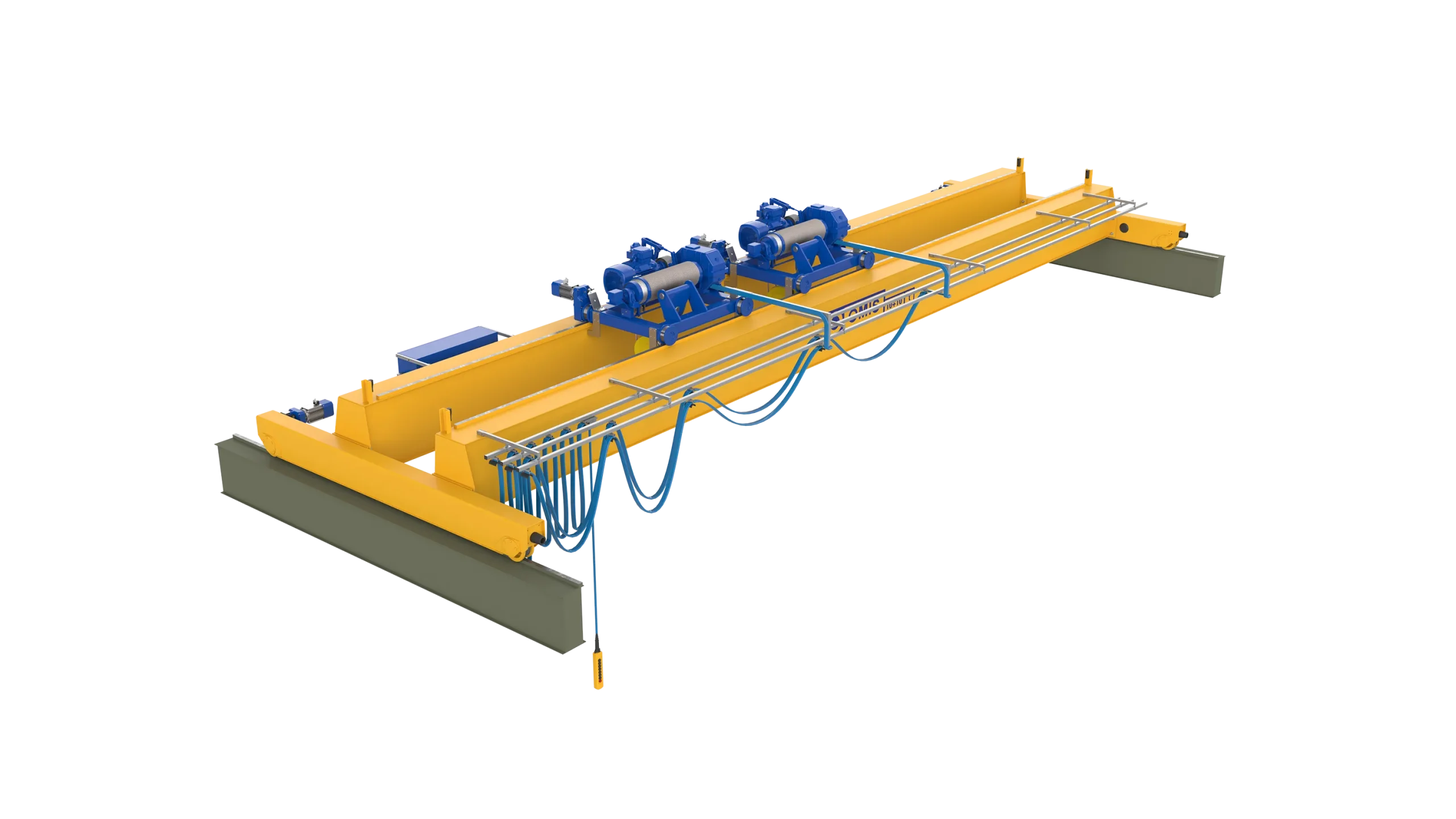

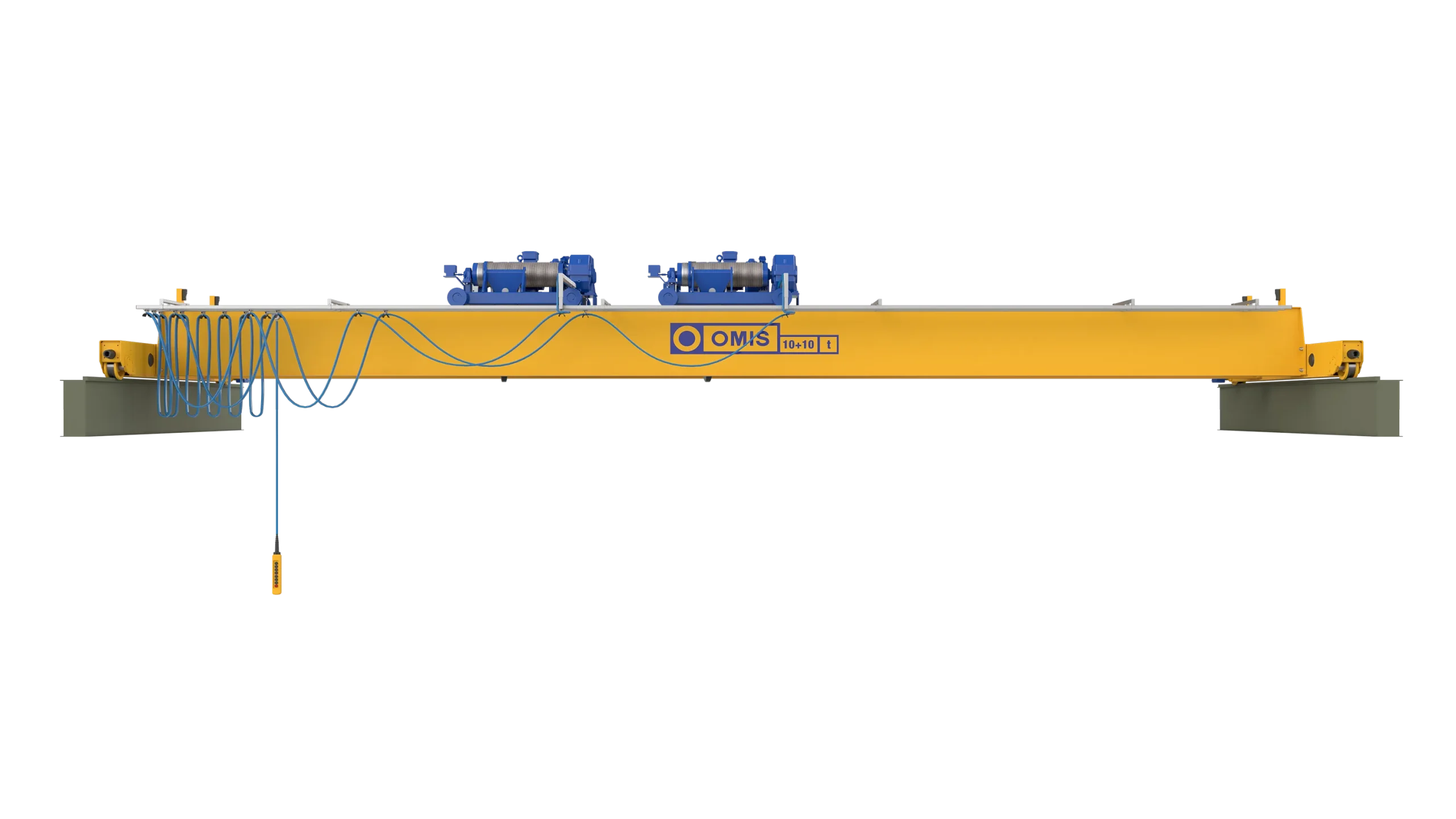

Double lifting for heavy loads

The optional installation of the twin hoist allows the easy transport of particularly bulky loads. This option offers advanced control, allowing rope hoists to be operated individually or in pairs, ensuring performance, safety and reliability during transport.

LED lamps for lighting the work area

The integration of LED lamps in the crane offers several advantages that help improve visibility and reduce shadows in the work area.

Weighing system

Weight indicators are integrated to accurately monitor the weight of the lifted load. The crane can be integrated with a weighing hook block and/or a display for easy and intuitive viewing of the weight of the lifted load.

System for detecting prohibited areas

This is a device designed to monitor and identify areas that are considered prohibited or dangerous. This type of system is often used in industrial environments, production areas, or places where it is necessary to track movement and prevent unauthorised access to certain sensitive areas.

Oscillation control

limits load oscillation by controlling the acceleration and deceleration of the bridge and trolley. The oscillation control allows faster load handling and more precise positioning. This feature also reduces the risk of damage to the load, the crane and the surrounding area.

End carriages with eight wheels for greater load capacity

The sliding head, consisting of eight wheels, ensures a load distribution that places less strain on the structure of the building. This allows heavier loads to be transported using the same runways, avoiding the need to reinforce existing buildings and optimising the efficiency and flexibility of lifting operations.

Easier maintenance

Equipping cranes with a maintenance walkway provides excellent accessibility to all components, bringing significant advantages, especially during maintenance activities. This simplifies inspection and maintenance operations, helping personnel to carry out work with greater ease and precision.

Runways and structures for crane operation

On request, custom metal support structures or custom solutions can be designed, ensuring that each specific requirement is met with precision and quality.

Picture Gallery

OMIS Service

Emergency response and scheduled maintenance. Repairs, upgrades, modifications and checks aimed at assessing residual life.

Born to innovate.

Raised to increase values.

OMIS is a manufacturer of excellence, a safe and reliable partner, a group that seeks and practices responsibility and sustainability. Technology, dialogue, sound principles and a forward-looking outlook fuel strategies, industrial approach and environmental awareness.