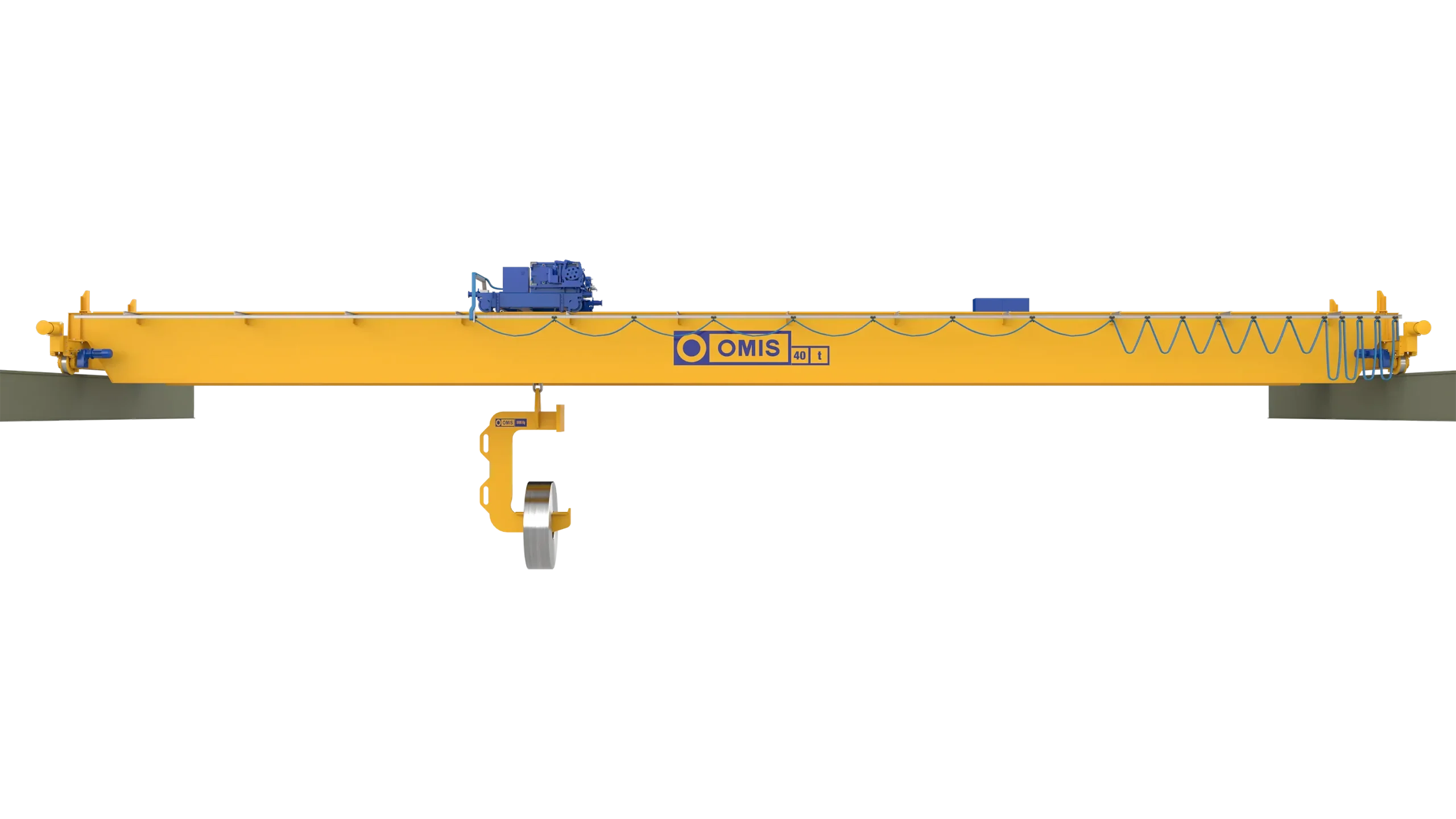

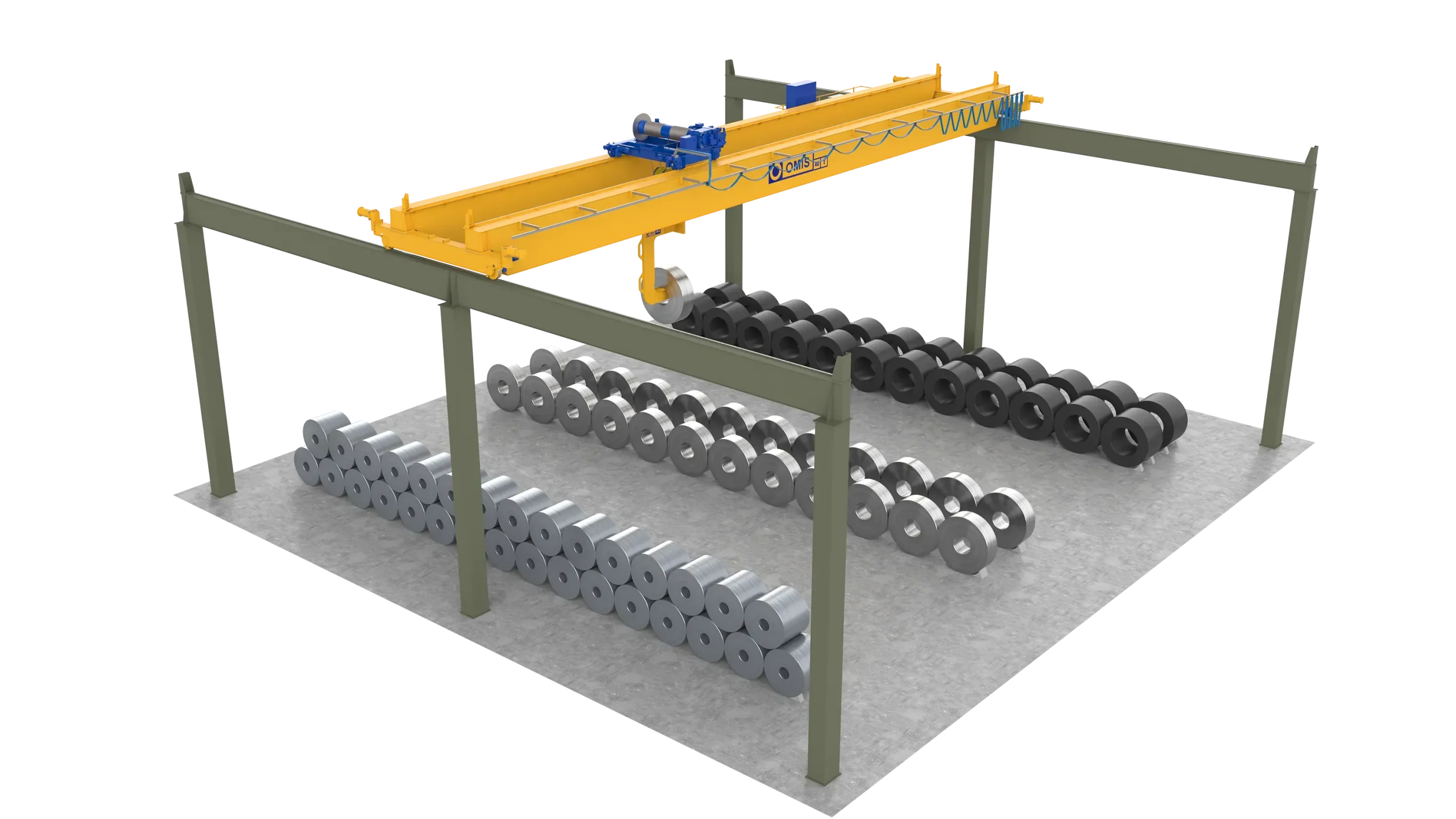

From 70 tonnes to capacities over 150 tonnes: large capacity overhead cranes, able to meet the most demanding requirements in terms of both structure and performance, ideal for the entire steel industry. OMIS has been designing and building them since its foundation, with hundreds of installations in various sectors of the steel industry, such as steel mills, generator production, power plants, forges and mould making. In addition, appropriate maintenance programmes are agreed with the customer to ensure optimum performance and a long service life for the machines.

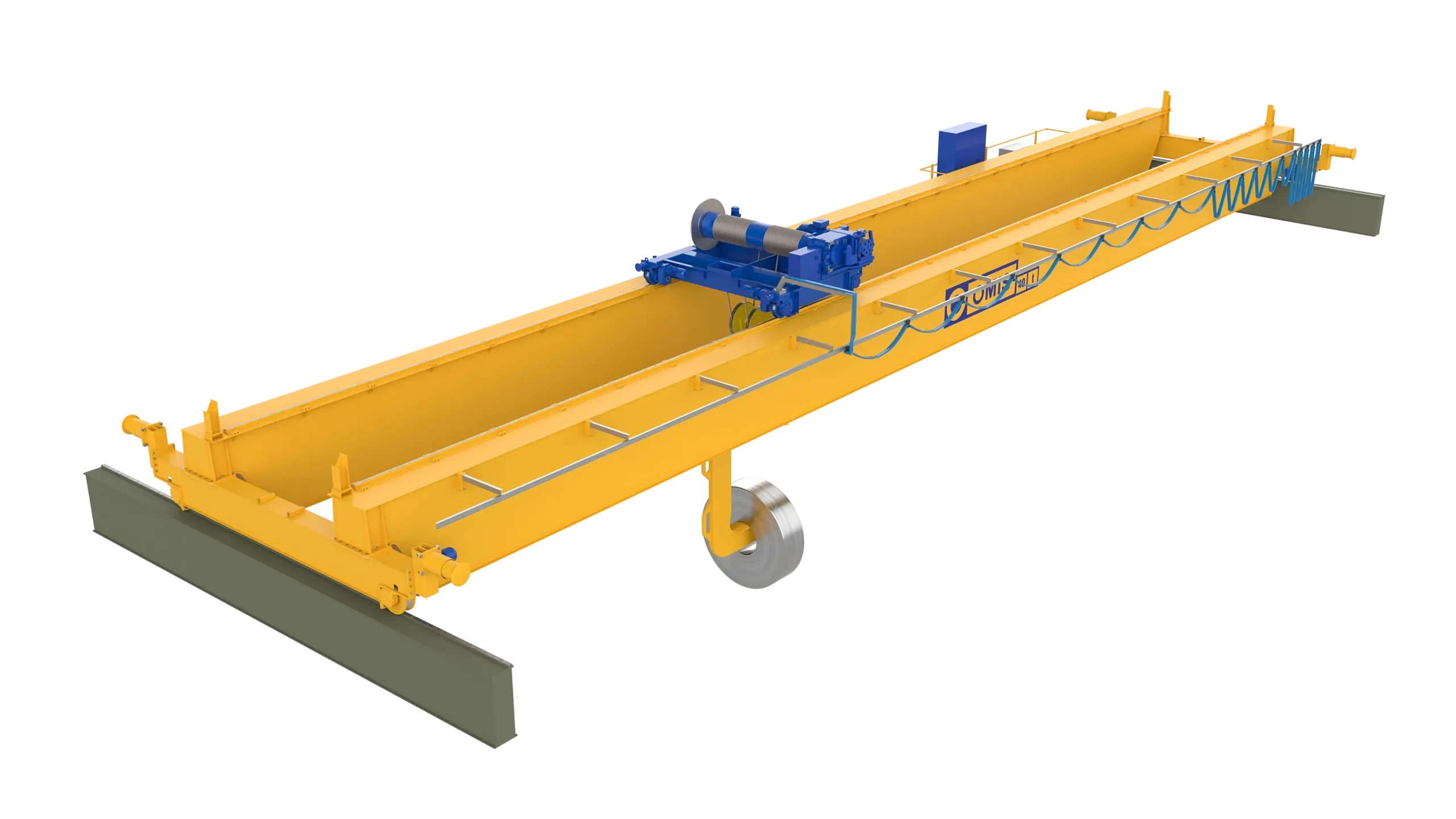

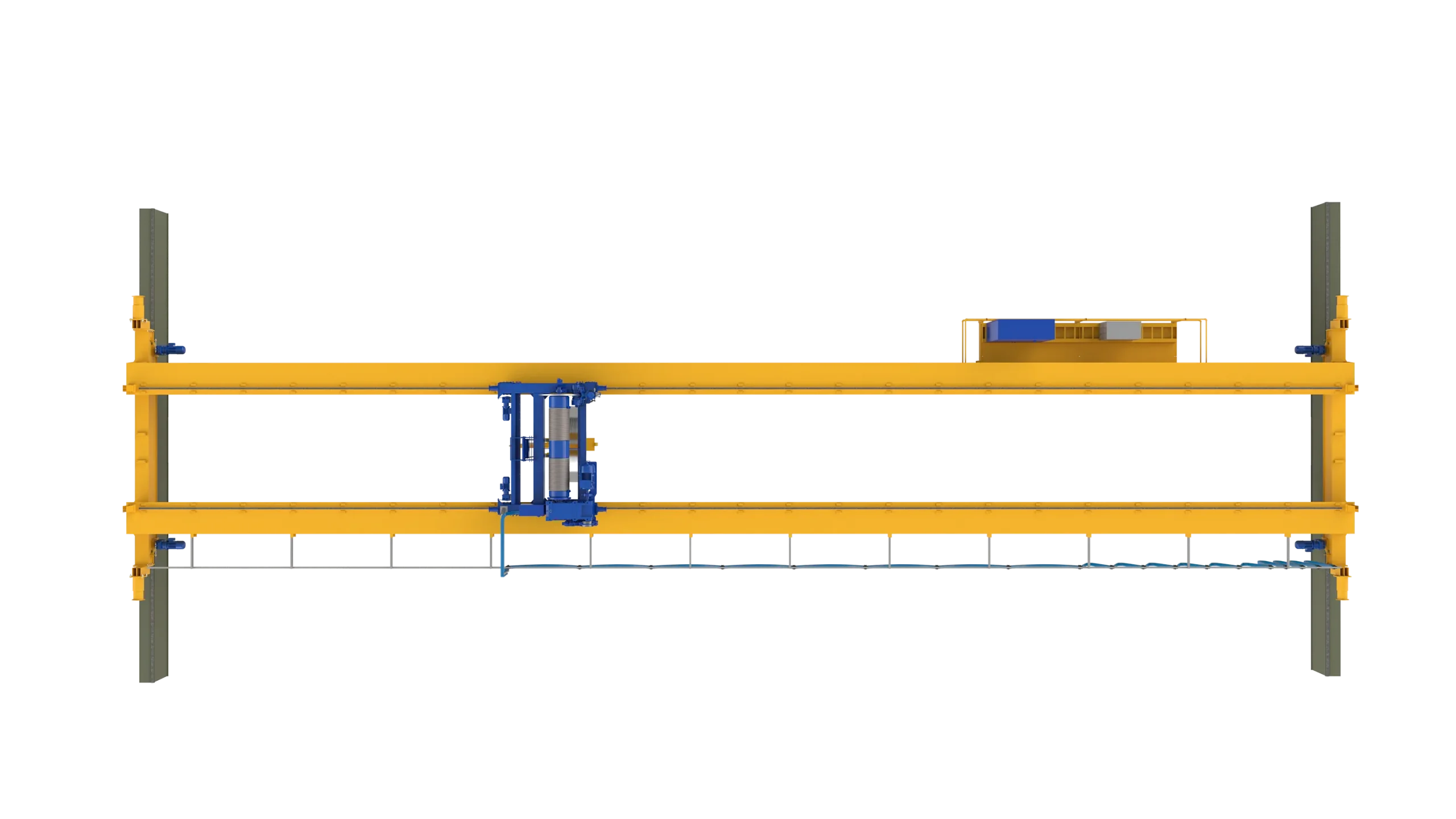

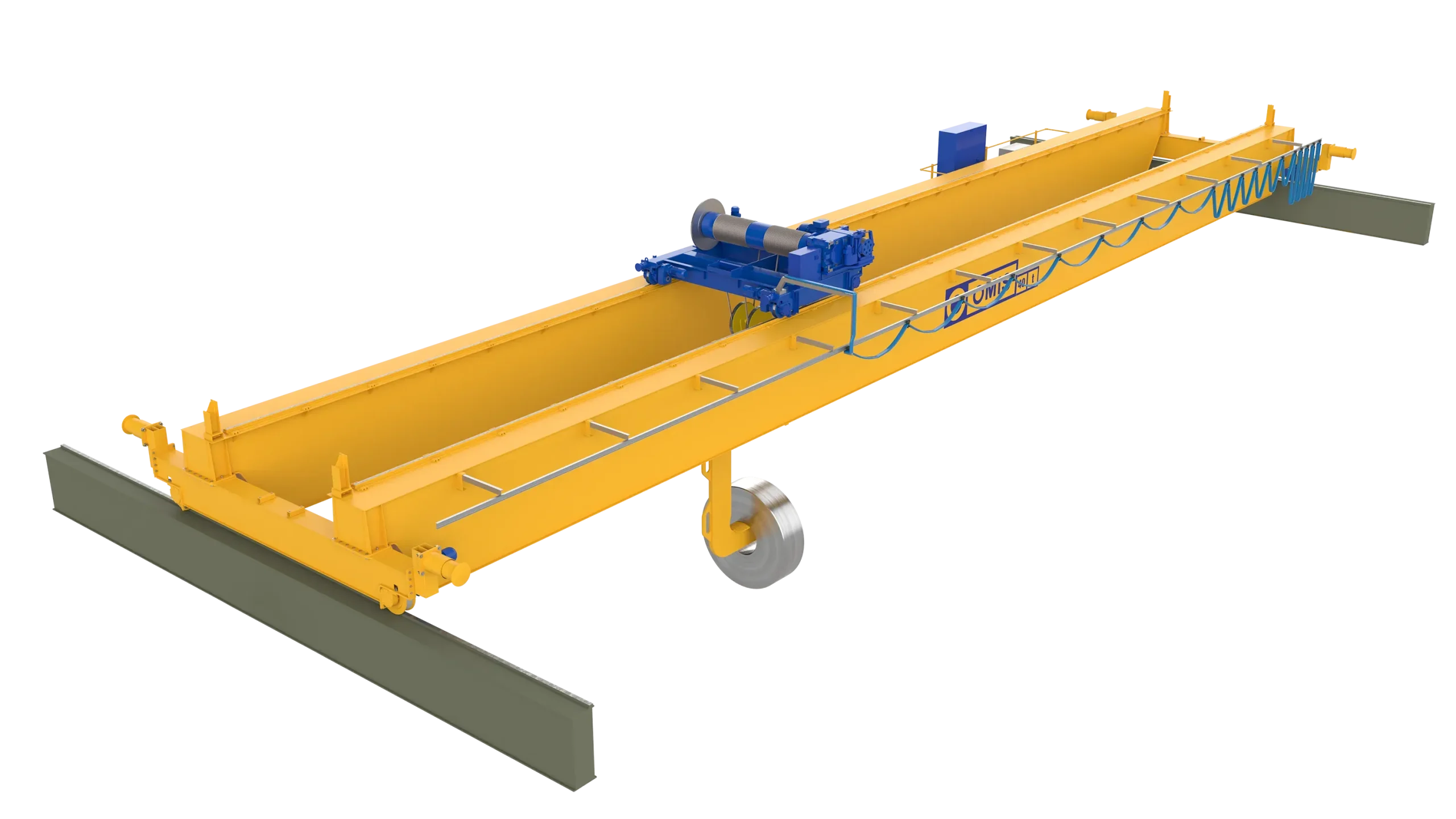

These cranes, like standard overhead cranes, are characterised by rationality and modularity in construction, ensuring high performance, high product reliability and ease of maintenance. OMIS overhead cranes for the steel industry are equipped with open barrel hoists designed and manufactured in our own factories, fitted with indirect action load limiting devices to guarantee safety and operational precision. Their presence over the entire working area guarantees safety, reliable performance and maximum lifting capacity. All movements are inverter-controlled, with the possibility of supplying solutions with dual-polarity motors on request. To meet the most stringent operational requirements of the steel industry, real A8/M8 class lifting and handling systems can be designed on request.

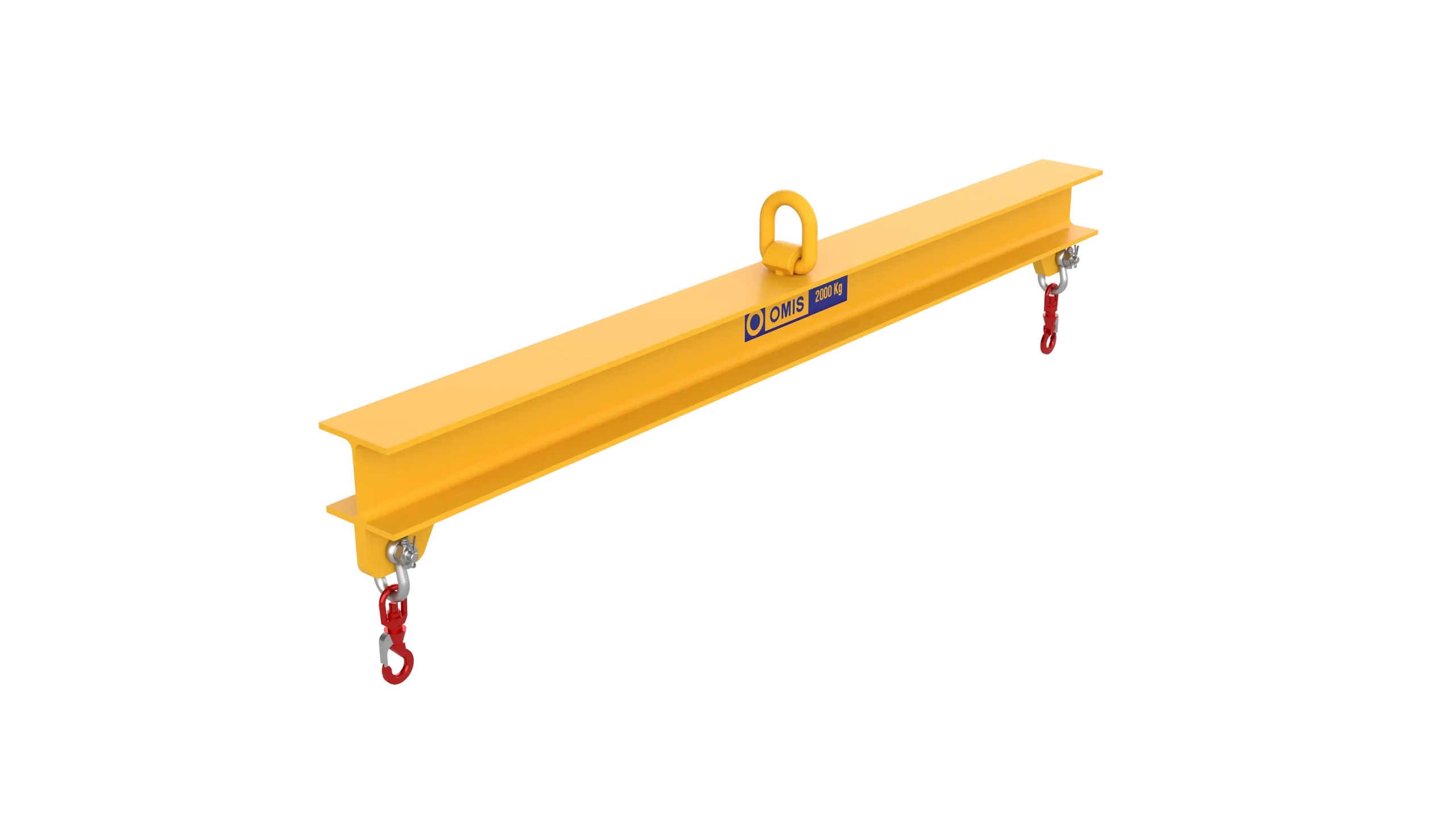

Among the most advanced optional features available for the double-girder bridge crane are the eight-wheel end carriages for increased load capacity, the electronic oscillation control system, the prohibited area detection system, work area lighting, weight indicators and synchronisation for handling long loads (master slave system). In cranes of this category, redundant components are often integrated to prevent unplanned downtime, which is critical in the steel industry where operational continuity is paramount. Bridge girders can be supplied with bolted joints, thus facilitating transport by container.

We are aware of the dangers and challenges in the metal production sector, such as intense heat, dangerous loads and the need for continuous production. Our advanced solutions, combined with modern and reliable service, help improve the safety and productivity of operations in every area of your plant. Thanks to our many years of experience and industry-specific expertise, our handling solutions are customised to meet every requirement of the steel process and meet the exacting demands of transport operations. We tackle challenging loads, ensuring reliable and versatile handling functions, even in high or extremely variable ambient temperatures.

Overhead cranes are used daily for loading and unloading heavy materials such as steel plates, coils, pipes and other goods. In some cases, overhead cranes can be used to easily handle and move reject materials, scrap or waste within the steel plant.

OMIS systems, in particular, can pick up hot slabs, billets or blooms and transport them safely within the shed, to the storage area, or load them directly onto goods trains. Our cranes for scrap yards are designed to work under continuous use, dealing with heavy loads and extremely demanding processes on a daily basis.

We pay special attention to the working environment for the crane operator, considering the high levels of dust, noise and vibration typical of the scrap yard environment.