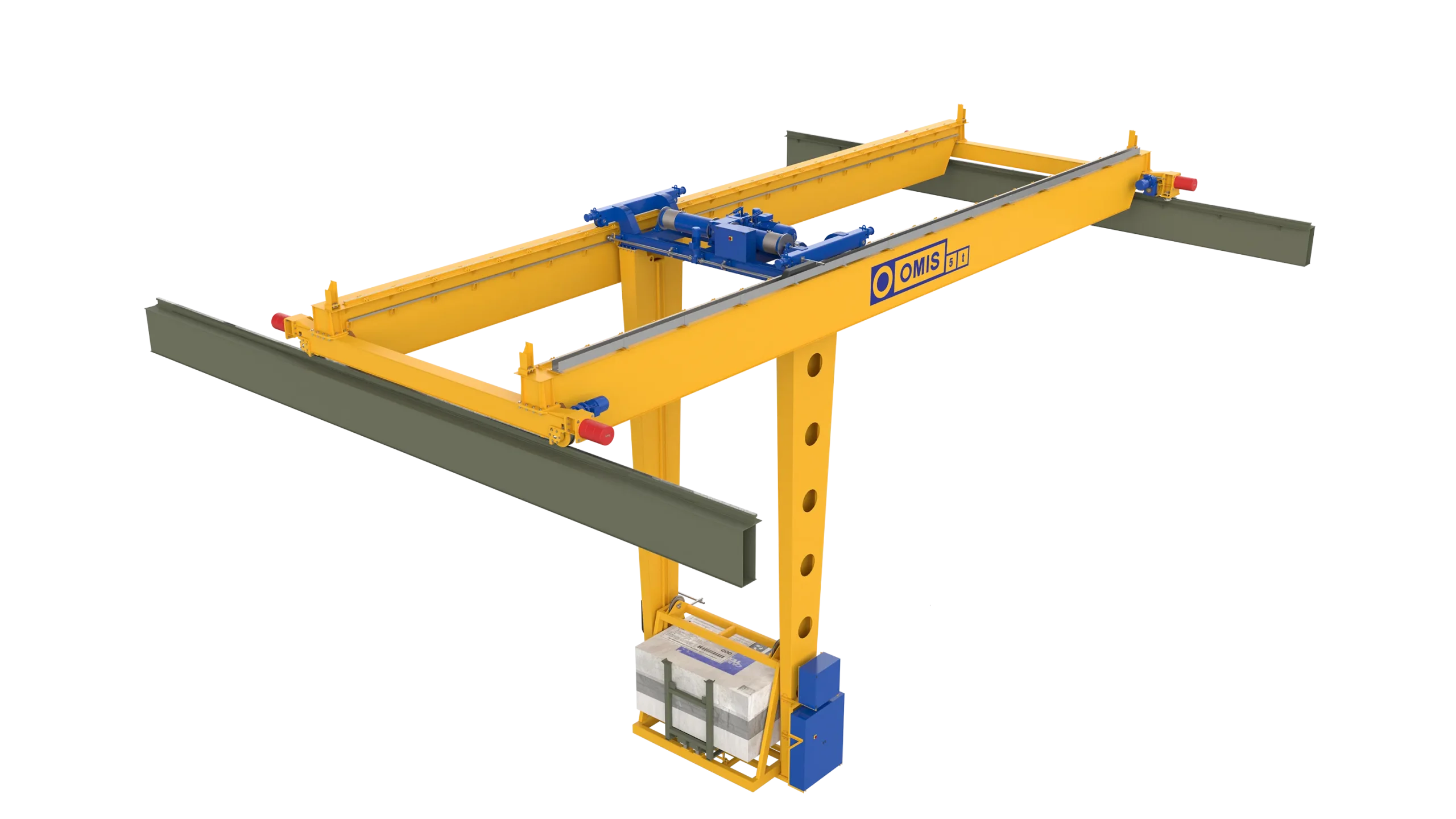

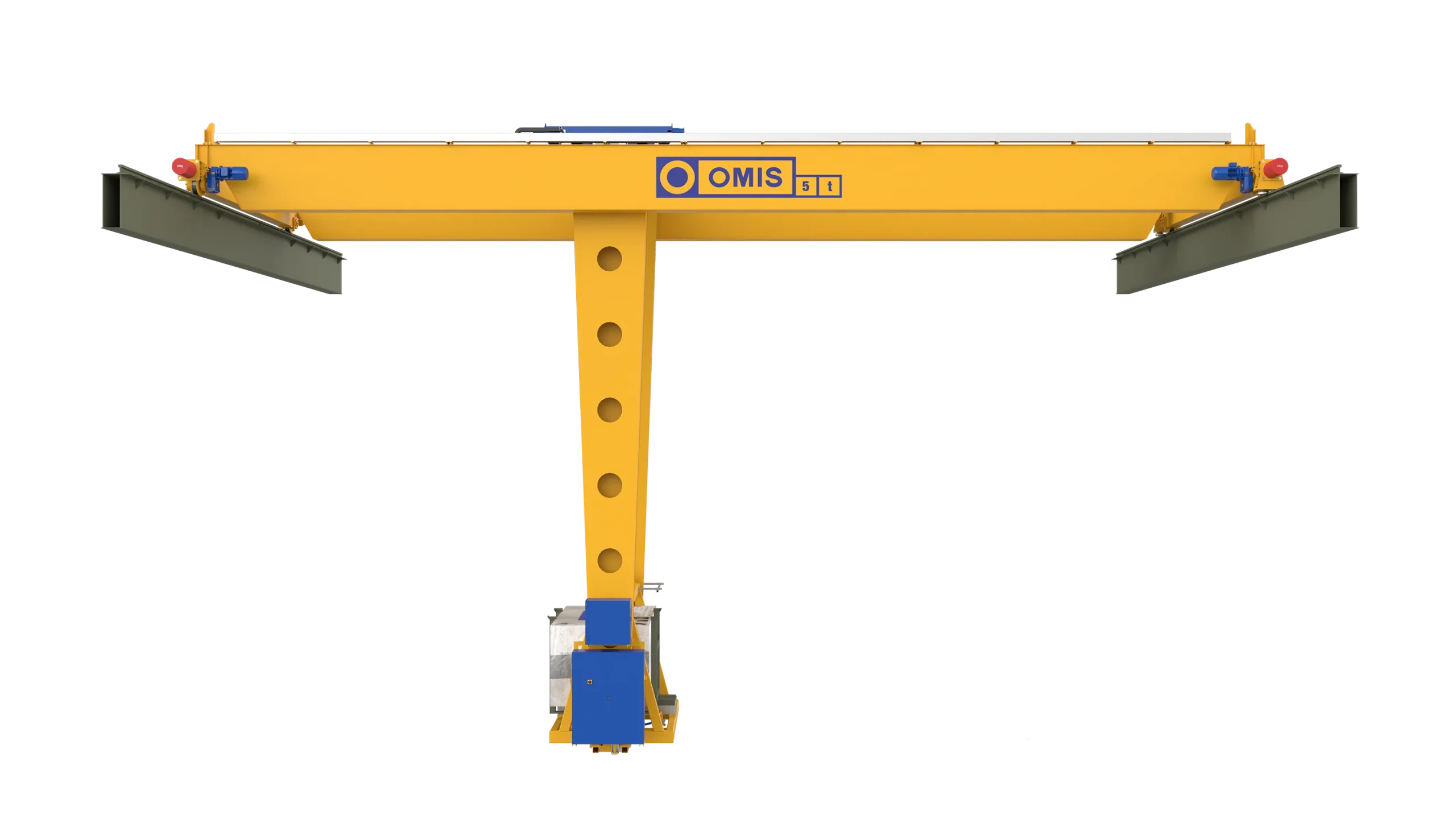

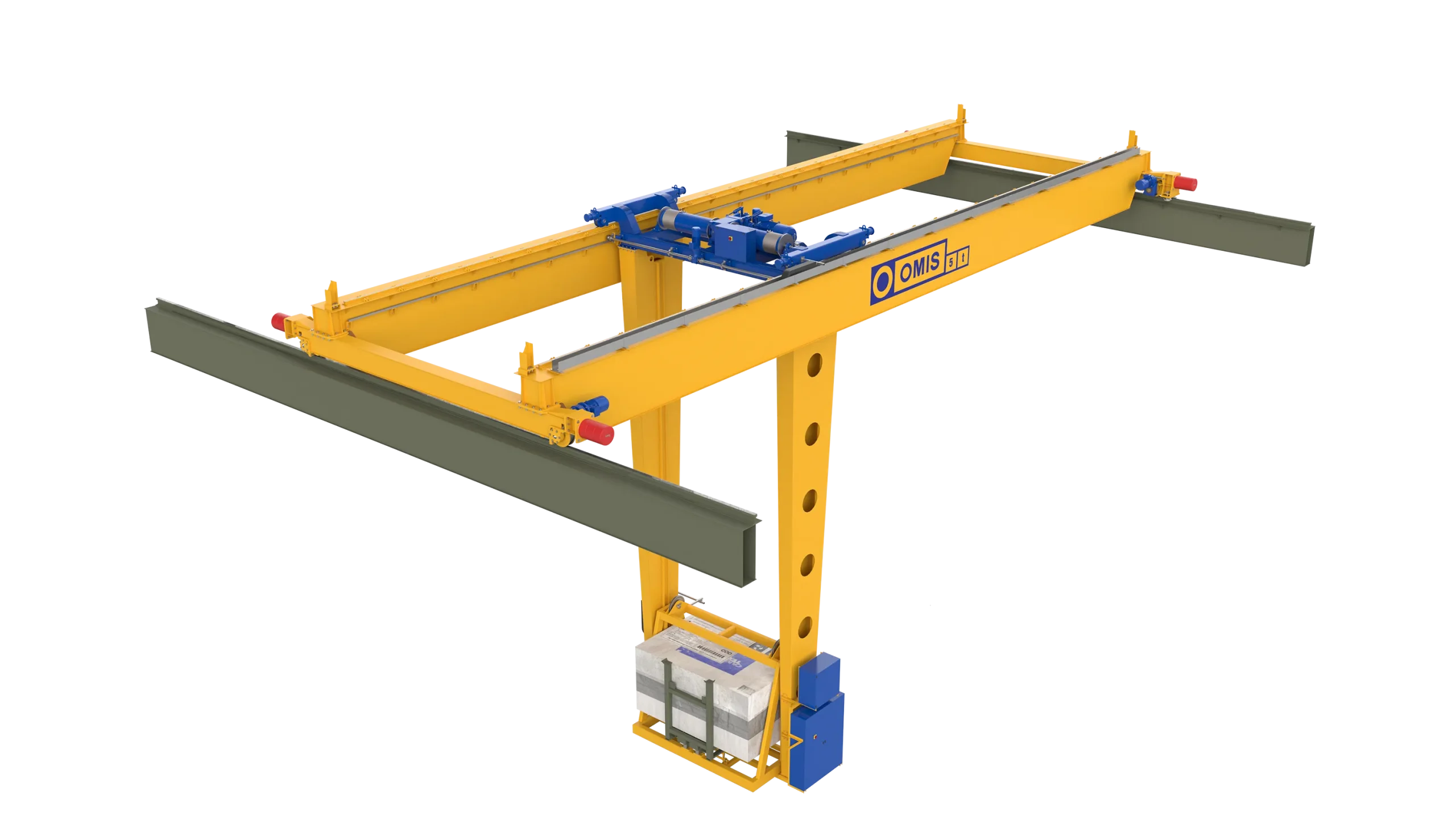

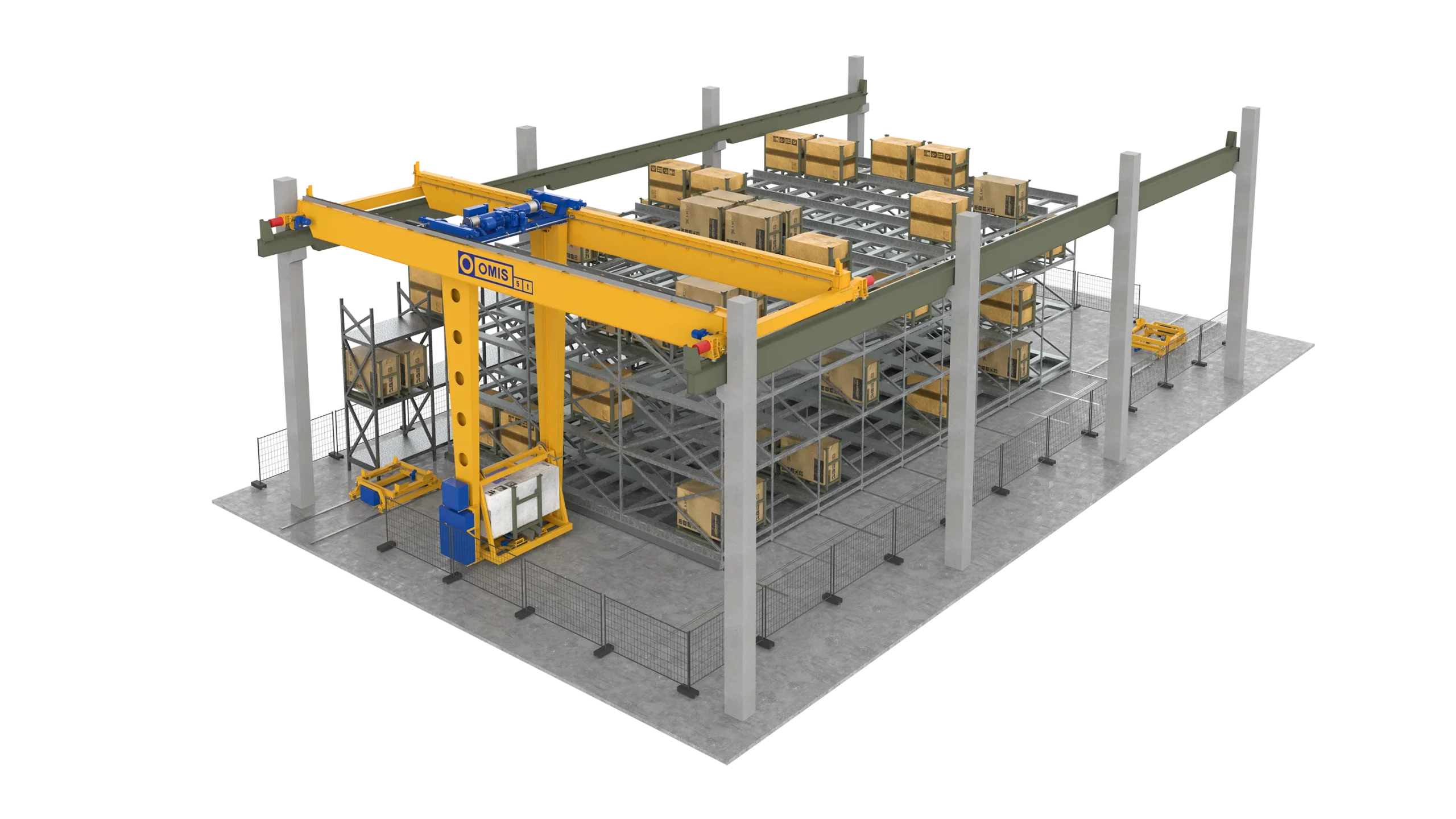

Automatic storage units equipped with overhead cranes are an advanced solution to the problems dictated by space and internal company logistics. Unique, fully customised systems, tailored to the real needs of the customer: a strategically optimised space with a segregated configuration and stacked storage units for maximum efficiency. Our range of automatic solutions is designed and manufactured in-house to meet the needs of companies in different sectors, operate in a continuous cycle and guarantee performance and safety.

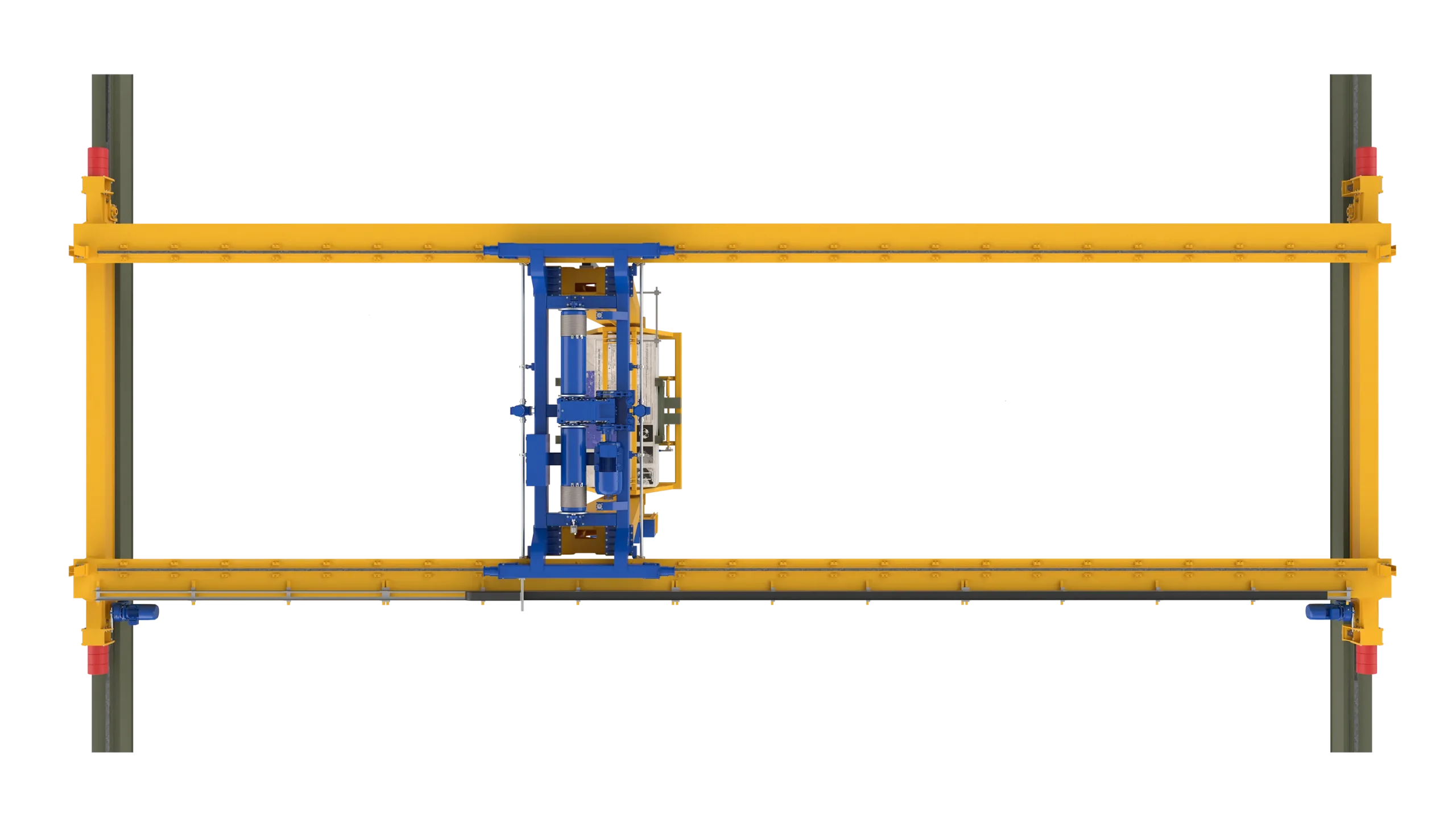

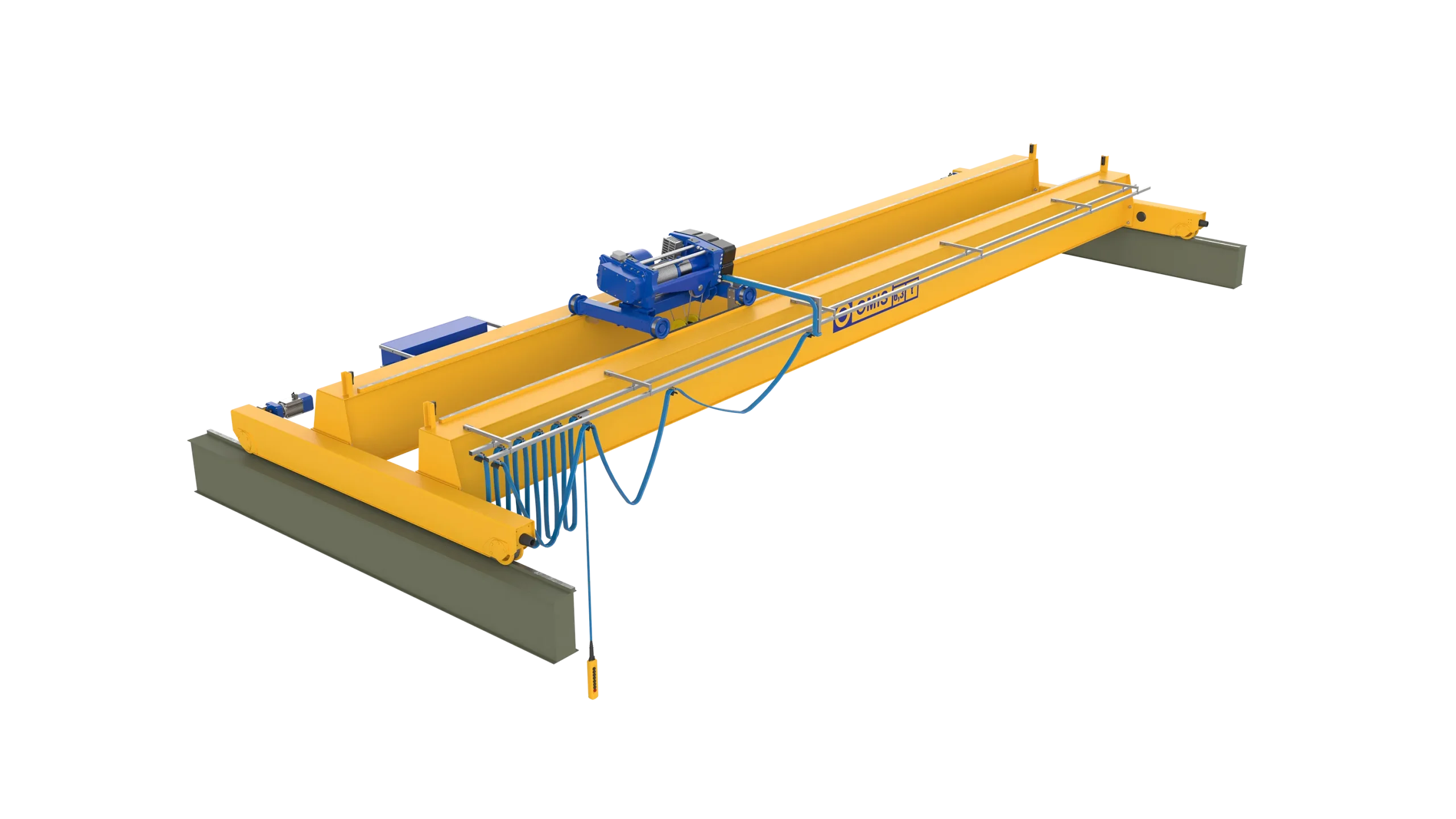

Gripping units, such as grippers or special tools, are custom-designed for the type of load to be moved. These can be electromagnets (for metal loads), vacuum tools (for paper reels), grippers (for special loads) or other specific variants. OMIS automatic storage units are a key asset for enhancing warehouse efficiency and internal logistics in various manufacturing sectors. From pantograph overhead cranes to those with automatic forks, the handling of goods is carefully planned and tracked at every stage of the production cycle, strategically optimising the storage and handling of materials of various weights and sizes and maximising the use of available space.

The introduction of automatic overhead cranes combined with mobile racking is a winning choice, allowing space to be fully and rationally utilised and making picking operations more accurate. Objects are identified using vision systems, sensors and optical readers that accurately recognise the type and quantity of parts to be moved. The addition of shuttles interconnected to the system allows the loading and unloading of material within departments in a strategic and fully automated manner. Thanks to specific gripping systems, the stacker cranes are able to handle and store various types of loading units, from small parts and pallets to bars and sheets, pipes and steel profiles. The management software makes it possible to control not only the automatic storage unit but the entire logic of the system, including the ground areas and crossing span shuttles during preparation or unloading of material. This way everything is ready and available at the right time for the production lines.

Right from the phase of analysing logistical needs and the specificities of the products to be stored, our staff works hand in hand with the customer to ensure maximum satisfaction.