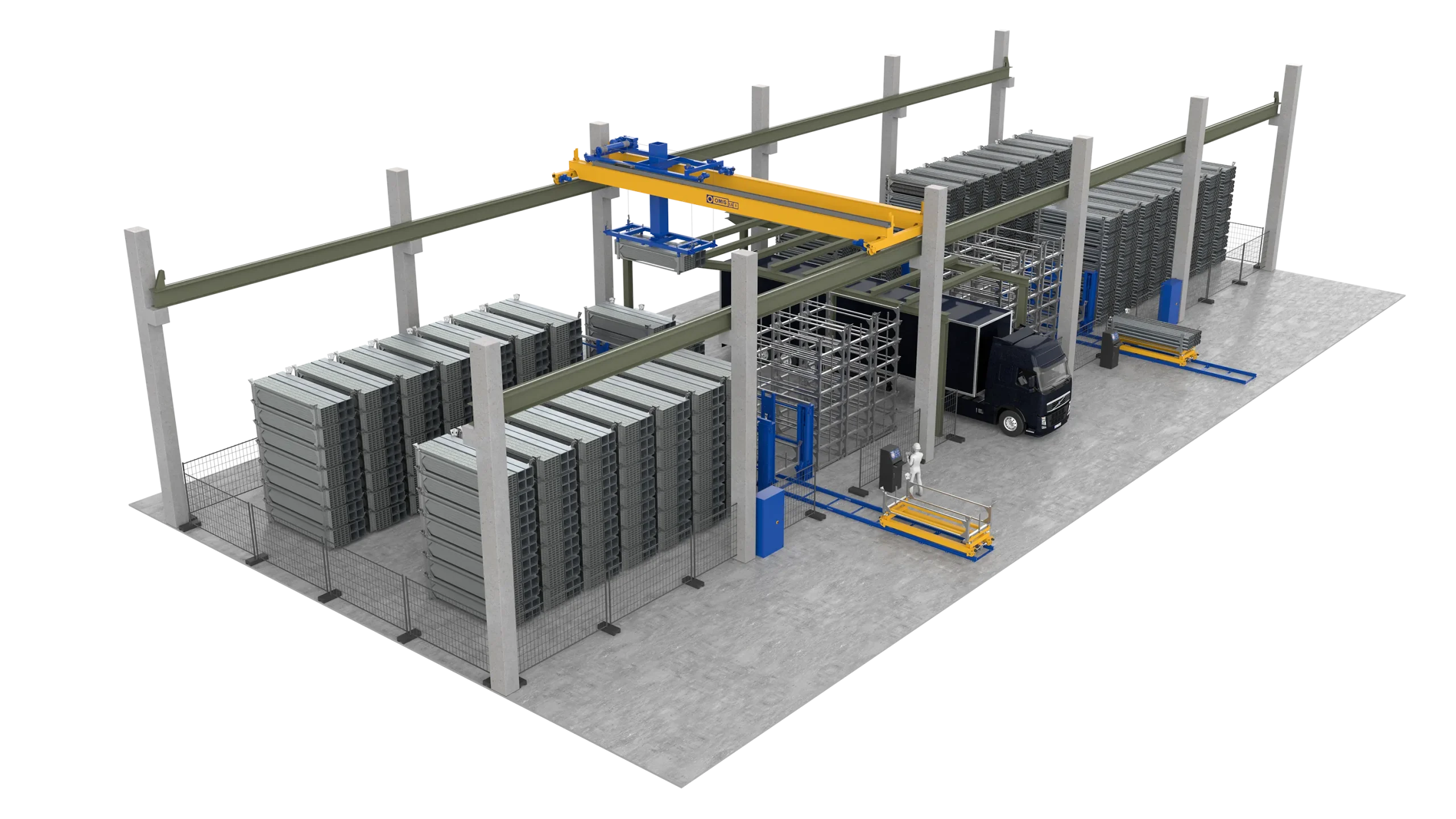

The automatic storage unit preserves all the advantages of the manual logistics system, utilising all available space and keeping errors to a minimum. Active in the distribution of iron and steel products, the Gruppo Commerciale Siderurgica Bresciana has been a customer of OMIS for many years, for lifting and handling solutions. In particular, the Lombardy-based company relied on OMIS for…

Designed to optimise production processes.

OMIS offers its expertise to the industry to develop solutions aimed at optimising production and thus reducing manpower costs.

Applicable in both waste management plants and coil storage areas, as well as in the management of vertical warehouses for billets or pallets, our software experts are able to maximise the excellent mechanical characteristics of this category of bridge cranes, allowing a significant reduction in handling times.

The use of automatic overhead cranes not only improves safety conditions, but is also recommended in environments with high personnel risk.

Our designers’ technical choices, based on the characteristics of the environment, aim for the maximum reliability of each component. These lifting systems allow large loads to be handled with precision and reliability. Managed by PLC, they allow complete or partial autonomy in handling loads for repetitive actions, guaranteeing reliability at constant work speeds. They contribute to the optimisation of production processes, improving handling times and rationalising the use of resources. In fact, the automatic movement of loads reduces downtime caused by incorrect handling operations.

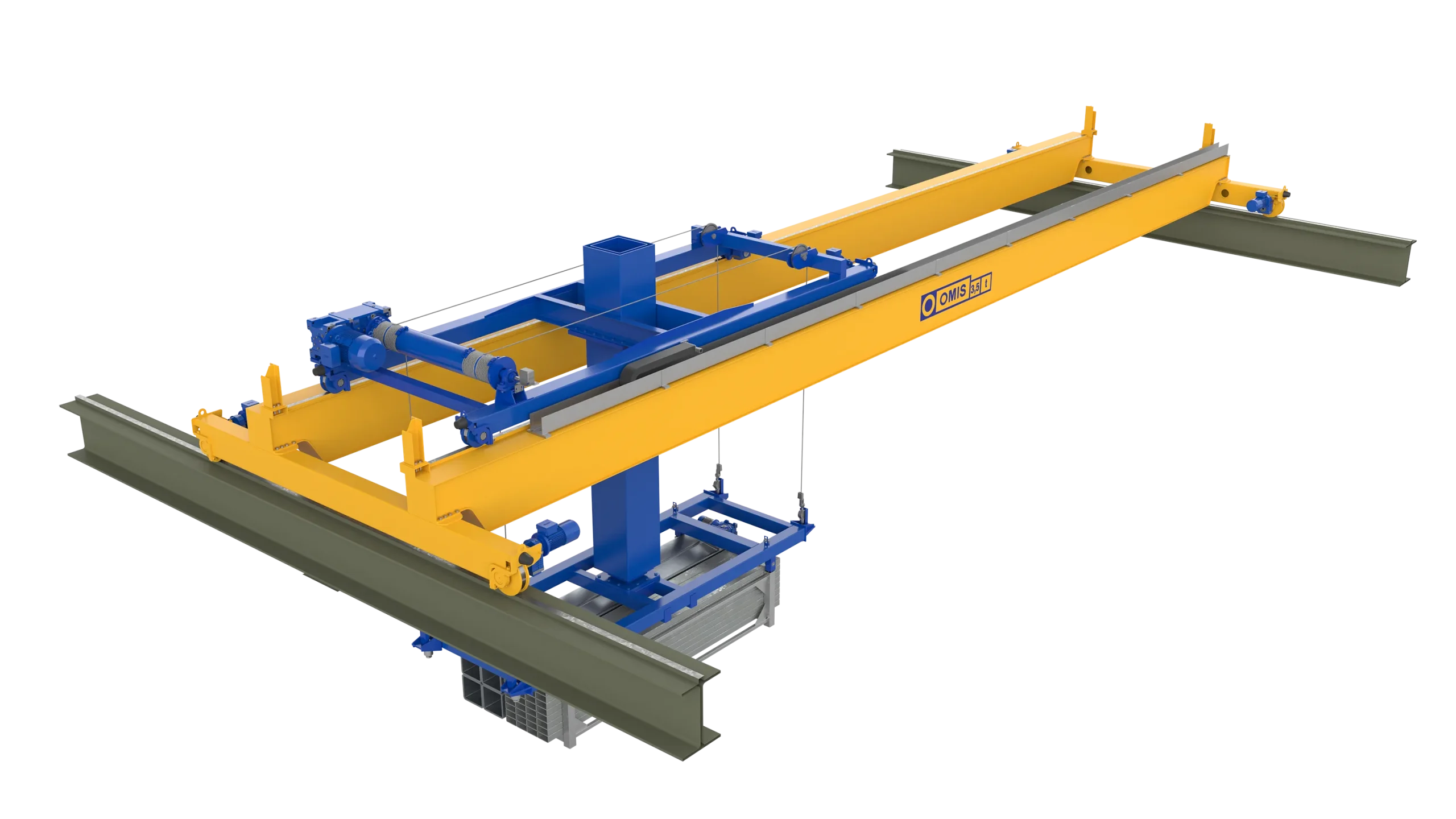

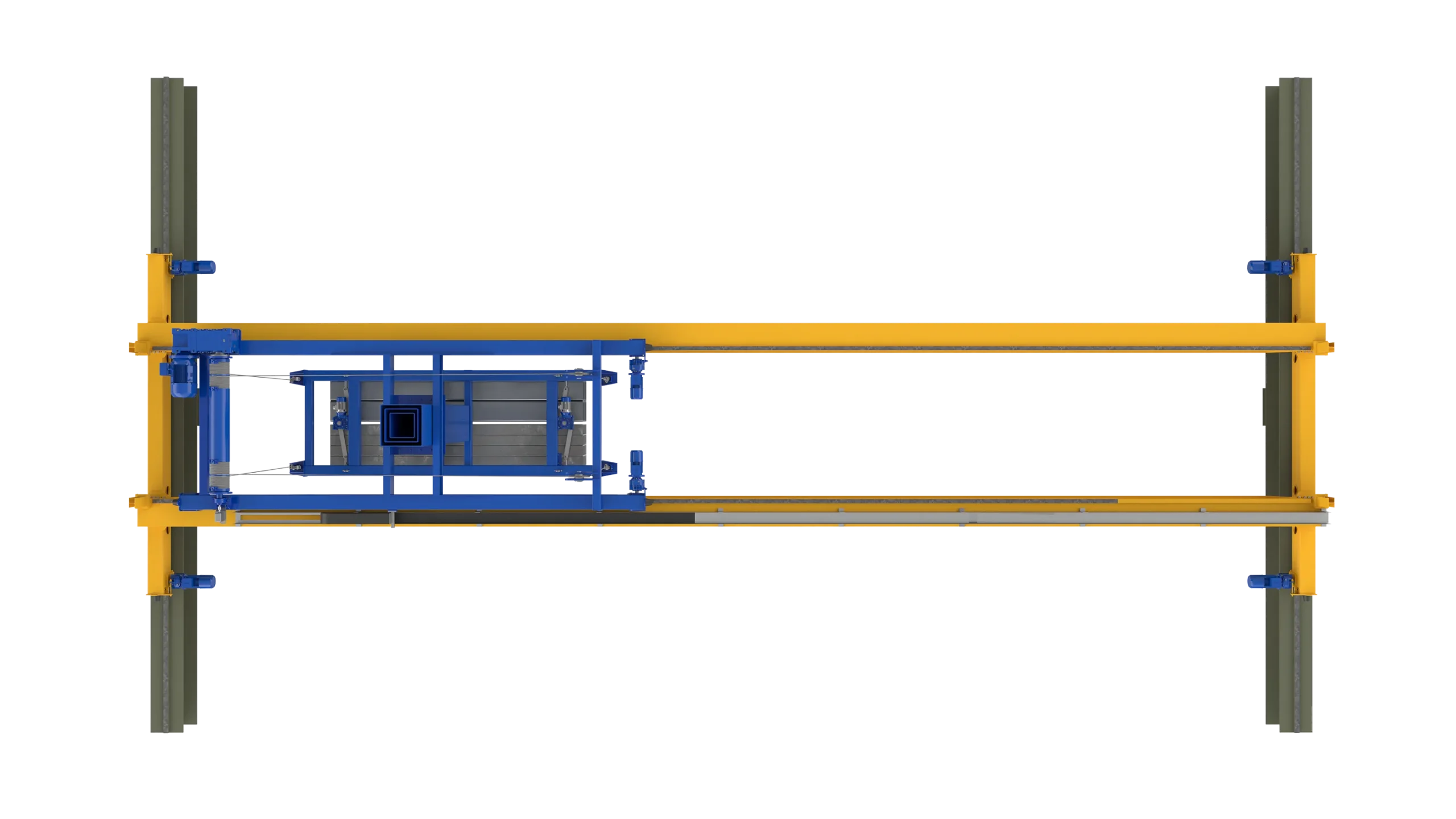

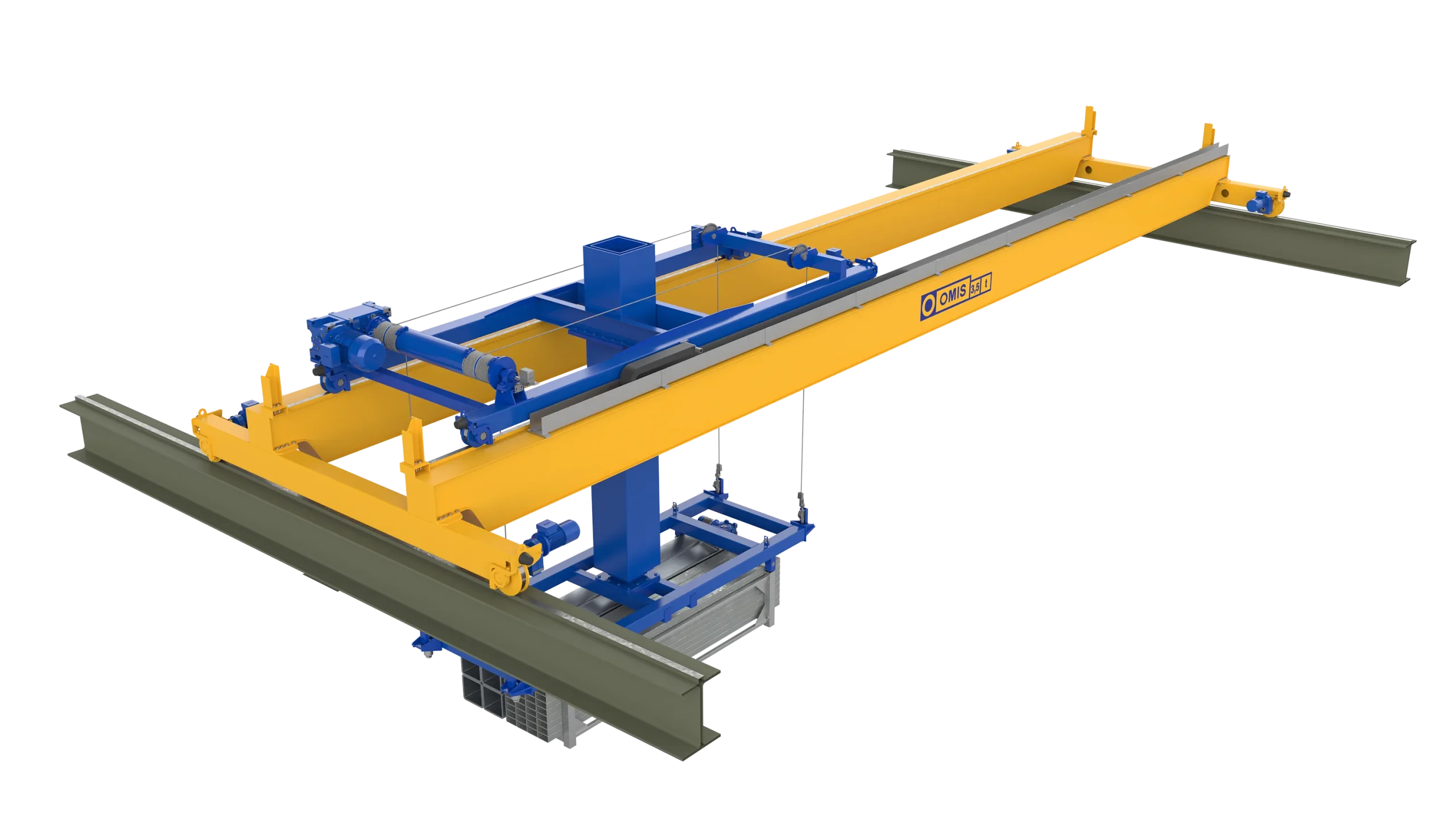

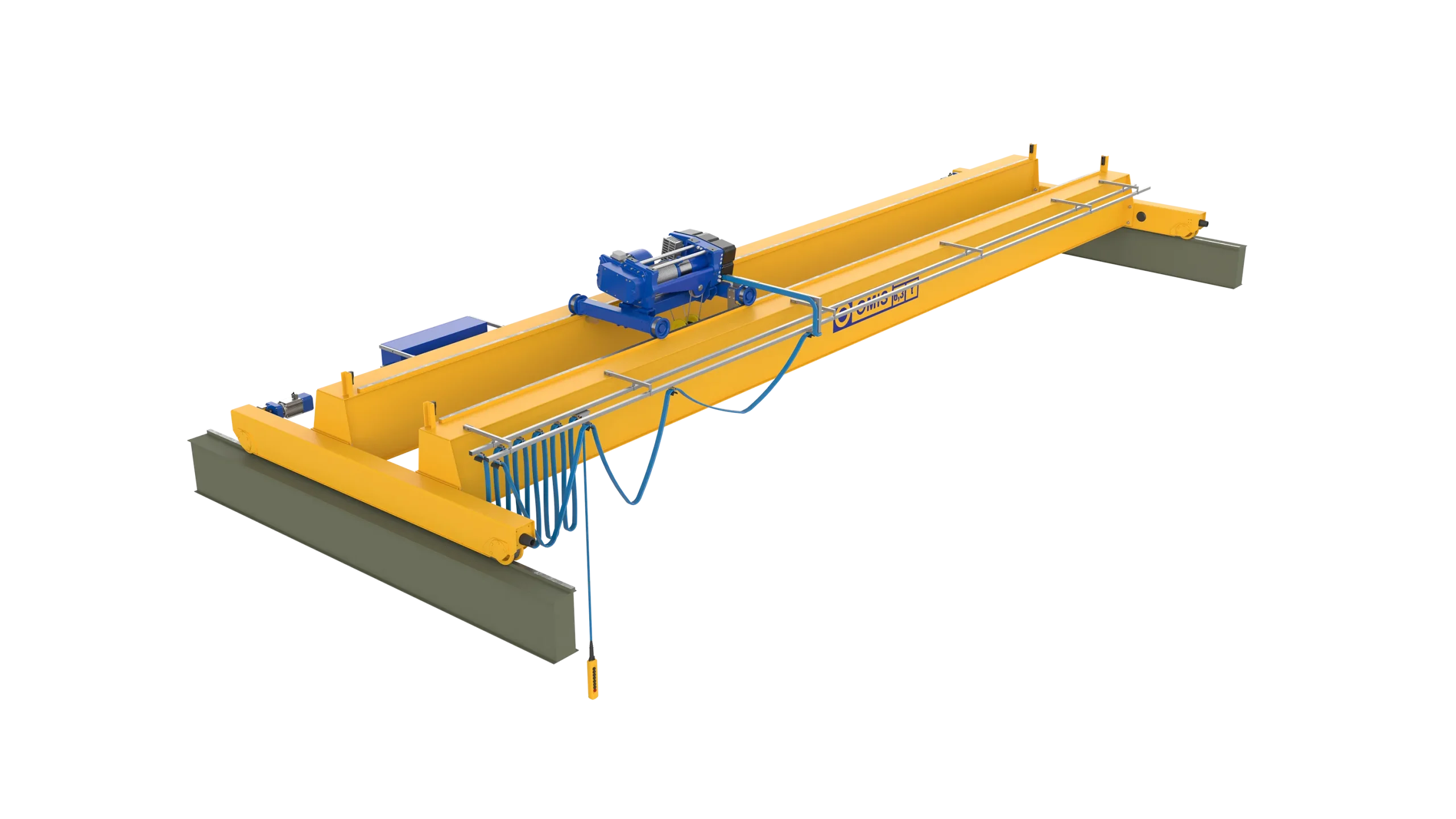

Automatic storage units equipped with overhead cranes provide an advanced solution characterised by a segregated configuration within a strategically optimised area, with units stored in a stacked manner. Gripping units, such as grippers, crossbars with magnets or suction cups, forks or other purpose-built devices, are custom-designed for the type of load to be moved. OMIS automatic overhead cranes are a key asset for enhancing warehouse efficiency and internal logistics in various manufacturing sectors. From the use of pantograph overhead cranes to those with telescopic guides, the handling of goods is carefully planned and tracked at every stage of the production cycle, strategically optimising the storage and handling of materials of various weights and sizes and maximising the use of available space.

Optimising the management of handling activities is crucial to avoid loss of time, damage and unnecessary handling, allowing significant savings in terms of manpower, space and handling time.

The implementation of dedicated automation systems for handling and storage management allows complete production tracking.

Our range is designed to handle the entire production process in different sectors, including storage and shipping, by adapting customised solutions to the specific needs of each application in the production process. The solutions used are subject to constant updates, so as to guarantee maximum suitability for all requirements that may arise from interaction with production facilities.

Right from the phase of analysing logistical needs and the specificities of the products to be stored, our staff works with the customer to ensure maximum satisfaction.

Benefits

Picture Gallery

Born to innovate.

Raised to increase values.

OMIS is a manufacturer of excellence, a safe and reliable partner, a group that seeks and practices responsibility and sustainability. Technology, dialogue, sound principles and a forward-looking outlook fuel strategies, industrial approach and environmental awareness.